Steel Plate_Sheet Weight Grade A36_A516 Gr.60_Gr.70

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

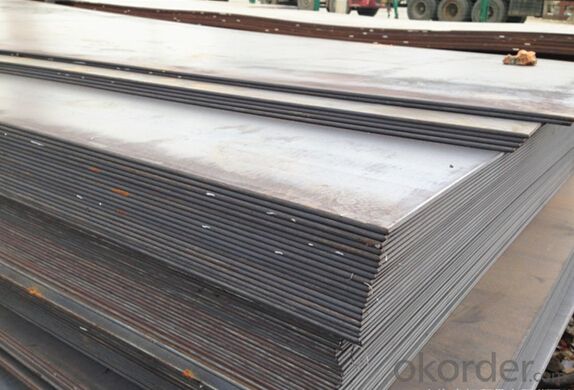

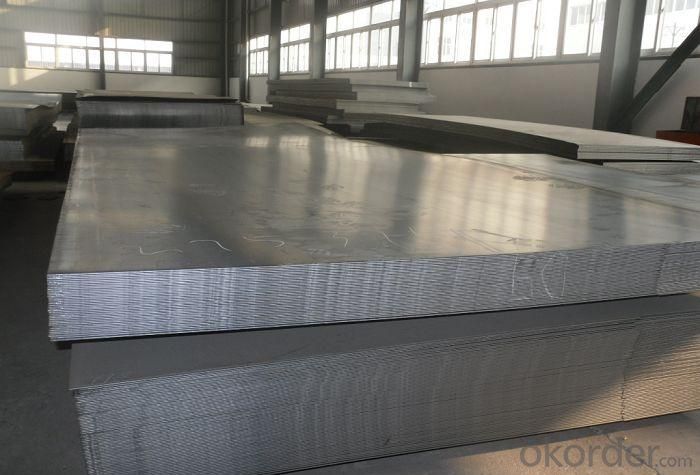

Steel Plate_Sheet Weight Grade A36_A516 Gr.60_Gr.70

Thickness:0.6-200mm

Width:1000-4000mm

MOQ: 1 ton

Certificate:ISO,SGS

Specification of Steel Plate_Sheet Weight Grade A36_A516 Gr.60_Gr.70

Commodity | Prime hot rolled carbon steel plate / sheet dimensions |

Thickness | 0.6-200mm |

Width | 1000-4000mm |

Length | as custom's request |

Technique | Cold rolled or hot rolled mild steel plate |

Surface treatment | Bare, galvanized coated or as customer's requirements. |

Standard | ASTM,EN,GB,JIS |

Material | A283Gr.D/A573Gr.65,A516Gr65,A516Gr70,A284Gr.D SS400,SS300,CCSB A36,A32,LRA32,LRB,Q235 SAE1010,SAE1020,SAE1045,Q195,Q235,Q345,SS400,ASTM A36,E235B mild steel plate |

Usage | the mild steel plate will used in home appliances construction, machinery manufacturing, container manufacturing, shipbuilding, bridges, etc. |

Terms of Payment | 30% T/T as deposit and 70% T/T balance againest B/L copy. |

Delivery Detail | Within 3-15 days after receipt of deposited for the mild steel plate |

CNBM Introduction of Steel Plate_Sheet Weight Grade A36_A516 Gr.60_Gr.70

CNBM International Corporation is the most import and export platform of CNBM group(China National Building Material Group Corporation) ,which is a state-owned enterprise, ranked in 270th of Fortune Global 500 in 2015.

With its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high quality series of refractories as well as technical consultancies and logistics solution.

After-sale service |

|

Advantages

|

|

Packaging & Delivery of Steel Plate_Sheet Weight Grade A36_A516 Gr.60_Gr.70

Packaging Detail | Sea worthy packing /as per customer's packing instruction |

Delivery Detail | 15 ~ 40 days after receiving the deposit |

Products

FAQ:

Are you a trading company or manufacturer? | Manufacturer |

What’s the MOQ? | 3 metric ton |

What’s your delivery time? | 15-35 days after downpayment received |

Do you Accept OEM service? | Yes |

what’s your delivery terms? | FOB/CFR/CIF |

What's the Payment Terms? | 30% as deposit,70% before shipment by T/T |

Western Union acceptable for small amount. | |

L/C acceptable for large amount. | |

Scrow ,Paybal,Alipay are also ok | |

Why choose us? | Chose happens because of quality, then price, We can give you both. Additionally, we can also offer professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposals. |

What's your available port of Shipment? | Main Port, China |

What’s your featured services? | Our service formula: good quality+ good price+ good service=customer's trust

|

Where are your Market? | Covering more than 160 countries in the world |

- Q: How is special steel tested for quality and durability?

- Special steel is tested for quality and durability through a series of rigorous tests and inspections. These tests typically include measuring mechanical properties such as tensile strength, hardness, and impact resistance. Additionally, non-destructive testing methods like ultrasonic and magnetic particle inspections are used to detect any internal defects or inconsistencies. Quality and durability are ensured by adhering to strict industry standards and specifications, and only steel that meets the required criteria is deemed suitable for use.

- Q: How is shock-resistant steel used in the production of impact tools?

- Shock-resistant steel is used in the production of impact tools because it has enhanced toughness and can withstand the high impact forces generated during use. This steel is specifically engineered to absorb and distribute the shock and vibrations produced when the tool strikes an object, reducing the risk of breakage and increasing the tool's overall lifespan.

- Q: What are the different testing methods used for special steel?

- Some of the common testing methods used for special steel include hardness testing, tensile testing, impact testing, metallographic examination, chemical analysis, and non-destructive testing. These methods help assess the mechanical properties, microstructure, chemical composition, and overall integrity of special steel, ensuring its suitability for various applications.

- Q: How does special steel contribute to the pharmaceutical aftermarket industry?

- Special steel plays a crucial role in the pharmaceutical aftermarket industry by offering several benefits that contribute to the overall efficiency and quality of pharmaceutical products. Firstly, special steel is highly resistant to corrosion and wear, making it ideal for manufacturing pharmaceutical equipment such as tanks, vessels, and pipelines. This resistance ensures that the equipment remains intact and free from contaminants, preventing any potential contamination of pharmaceutical products. Moreover, special steel possesses excellent heat resistance properties, allowing it to withstand high temperatures without deforming or degrading. This is particularly important in pharmaceutical manufacturing processes that involve the use of heat, such as sterilization or drying. The heat resistance of special steel ensures that the equipment remains stable and reliable throughout these processes, guaranteeing the safety and efficacy of pharmaceutical products. Furthermore, special steel is known for its high strength and durability, enabling it to withstand rigorous usage in the pharmaceutical industry. This is particularly important in the aftermarket industry, where pharmaceutical equipment may undergo frequent repairs or modifications. The strength and durability of special steel ensure that the equipment can be easily maintained and repaired, reducing downtime and minimizing costs for pharmaceutical companies. Additionally, special steel offers excellent hygiene properties, as it can be easily cleaned and sanitized. This is crucial in the pharmaceutical industry, where strict hygiene standards are essential to prevent any contamination or cross-contamination of pharmaceutical products. The ease of cleaning and sanitization provided by special steel ensures that pharmaceutical equipment remains free from any potential sources of contamination, maintaining the integrity and quality of the products. In summary, special steel contributes significantly to the pharmaceutical aftermarket industry by providing corrosion resistance, heat resistance, strength, durability, and excellent hygiene properties. These features ensure the integrity, safety, and efficacy of pharmaceutical products, while also reducing maintenance costs and downtime for pharmaceutical companies. Therefore, special steel plays a vital role in the overall efficiency and success of the pharmaceutical aftermarket industry.

- Q: What are the different types of mold steel?

- There are several different types of mold steel, including P20, H13, S7, and 420 stainless steel. Each type has its own unique properties and is used for specific applications in mold making and injection molding processes. P20 is a versatile mold steel that offers good machinability and wear resistance. H13 is a hot work tool steel known for its high heat resistance and toughness. S7 is a shock-resistant mold steel suitable for applications requiring high impact resistance. 420 stainless steel is corrosion resistant and commonly used for molds that require good polishing and texturing.

- Q: How does special steel contribute to national security?

- National security is significantly enhanced by special steel, which serves various purposes. Firstly, it is extensively utilized in the production of military equipment and weapons. Tanks, armored vehicles, submarines, and aircraft carriers require special steel due to its exceptional strength, resilience, and resistance to corrosion. Incorporating special steel into military applications ensures the durability and reliability of these vital defense systems, ultimately strengthening national security. Secondly, special steel plays a pivotal role in the construction of critical infrastructure. Bridges, tunnels, and buildings, which are essential for a nation's functioning and security, rely on special steel. Its unparalleled strength and ability to withstand extreme conditions make it a crucial material for structures that must endure natural disasters, terrorist attacks, or other security threats. By incorporating special steel into infrastructure projects, a nation can fortify its security and safeguard its citizens. Additionally, special steel is of utmost importance in the energy sector, particularly within nuclear power plants. Special steel alloys are employed in the construction of reactor vessels and other components that encounter high temperatures and pressures. The utilization of special steel ensures the integrity and safety of these critical facilities, mitigating the risk of potential nuclear accidents that could pose significant threats to national security. Lastly, special steel contributes to national security by supporting the defense industry and fostering technological advancements. Research and development in special steel alloys often lead to breakthroughs in material engineering, which can have broader applications beyond defense. These advancements stimulate innovation in sectors such as aerospace, automotive, and energy, thereby augmenting a nation's overall technological capabilities and economic competitiveness. In conclusion, special steel's contribution to national security is multifaceted. Its incorporation in military equipment, critical infrastructure, nuclear power plants, and technological advancements all play a pivotal role in safeguarding a nation's interests, protecting its citizens, and maintaining its strategic advantage in an increasingly turbulent world.

- Q: What are some examples of special steel alloys?

- Some examples of special steel alloys include stainless steel, tool steel, high-speed steel, alloy steel, and maraging steel.

- Q: What are the different methods of improving the impact toughness of special steel?

- There are several methods that can be employed to enhance the impact toughness of special steel. Here are a few commonly used techniques: 1. Heat Treatment: One of the most effective methods is heat treatment, which involves subjecting the steel to specific heating and cooling processes. For instance, quenching and tempering can significantly increase the impact toughness of steel. Quenching involves rapidly cooling the heated steel in a liquid medium such as oil or water, while tempering involves reheating the quenched steel to a specific temperature and then cooling it slowly. This process helps to refine the microstructure of the steel, making it more resistant to fracture and improving its impact toughness. 2. Alloying: Another method is alloying, which involves adding specific elements to the steel composition. Alloying elements such as nickel, chromium, and molybdenum can enhance the toughness of steel by modifying its microstructure and improving its resistance to impact. These alloying elements help in reducing the formation of brittle phases and improving the ductility of the steel. 3. Grain Refinement: The grain size of steel plays a crucial role in determining its impact toughness. By refining the grain size, the steel can exhibit improved toughness. This can be achieved through methods like controlled rolling or severe plastic deformation techniques. These techniques help in breaking down the large grains and promoting the formation of smaller, more uniform grains, resulting in enhanced toughness. 4. Shot Peening: Shot peening is a surface treatment technique that involves bombarding the steel surface with small metallic or ceramic shots. This process induces compressive stress on the surface, which helps to improve the impact toughness by reducing the likelihood of crack propagation. 5. Welding Techniques: In the case of welding special steel, specific welding techniques can be employed to enhance its impact toughness. Preheating the steel before welding and controlling the welding parameters such as heat input and cooling rate can help in reducing the formation of brittle phases and improving the toughness of the welded joint. It is important to note that the selection of the appropriate method for improving the impact toughness of special steel depends on various factors such as the desired level of toughness, the specific steel composition, and the intended application of the steel. Therefore, a comprehensive understanding of the steel's properties and the specific requirements is crucial in determining the most suitable method for enhancing its impact toughness.

- Q: How is special steel used in the production of springs?

- Special steel is used in the production of springs due to its high strength and durability. The unique properties of special steel allow springs to withstand heavy loads and retain their shape even under extreme conditions. This enables springs to function effectively in various applications such as automotive, aerospace, manufacturing, and more.

- Q: Can special steel be used in the manufacturing of precision instruments?

- Indeed, precision instruments can benefit from the utilization of special steel. Special steel encompasses a range of steel types that have been purposefully crafted and processed to possess specific attributes, such as heightened strength, hardness, resistance to corrosion, and thermal stability. These unique qualities render special steel highly suitable for applications necessitating precision and accuracy, such as precision instrument manufacturing. Precision instruments, such as surgical tools, measuring devices, optical instruments, and scientific equipment, necessitate materials capable of retaining dimensional stability and enduring extreme conditions. Special steels, such as stainless steel, tool steel, and high-speed steel, provide exceptional mechanical properties, including remarkable tensile strength, resistance to wear, and dimensional stability. Consequently, these kinds of steel are well-suited for the production of precision instruments. Moreover, special steel can be engineered to possess specific characteristics, such as low magnetic permeability or excellent resistance to temperature fluctuations. These attributes prove particularly vital in precision instruments, as magnetic interference or temperature variations have the potential to impact their performance. To summarize, special steel can indeed be employed in the manufacturing of precision instruments due to its exceptional mechanical properties, dimensional stability, and ability to withstand harsh conditions. Its versatility enables the production of precision instruments of superior quality, fulfilling the stringent requirements of various industries, including the medical, scientific, and engineering sectors.

Send your message to us

Steel Plate_Sheet Weight Grade A36_A516 Gr.60_Gr.70

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords