Hot Rolled JIS Standard H-beam Steel Bar

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Hot Rolled JIS Standard H-beam Steel Bar at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Commercial building structure ;Pre-engineered buildings; Machinery support structure; Prefabricated structure; Medium scale bridges; Ship-building structure. etc.

Product Advantages:

OKorder's Hot Rolled JIS Standard H-beam Steel Bar are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Specifications of Hot Rolled Steel H-beam For Sale

1. Standard: JIS

2. Grade: SS400

3. Length: 12m

4. Invoicing on theoretical weight or actual weight as customer request

5.Payment: TT or L/C

6. Sizes:

H x B

(mm)

| T1 | T2 | JIS Weight

(kg/m)

| GB Weight

(kg/m)

|

100*100 | 6 | 8 | 16.9 | 17.2 |

125*125 | 6.5 | 9 | 23.6 | 23.8 |

150*75 | 5 | 7 | 14 | 14.3 |

148*100 | 6 | 9 | 20.7 | 21.4 |

150*150 | 7 | 10 | 31.1 | 31.9 |

175*90 | 5 | 8 | 18 | 18.2 |

175*175 | 7.5 | 11 | 40.4 | 40.4 |

198*99 | 4.5 | 7 | 17.8 | 18.5 |

200*100 | 5.5 | 8 | 20.9 | 21.7 |

194*150 | 6 | 9 | 29.9 | 31.2 |

200*200 | 8 | 12 | 49.9 | 50.5 |

248*124 | 5 | 8 | 25.1 | 25.8 |

250*125 | 6 | 9 | 29 | 29.7 |

244*175 | 7 | 11 | 43.6 | 44.1 |

250*250 | 9 | 14 | 71.8 | 72.4 |

298*149 | 5.5 | 8 | 32 | 32.6 |

298*201 | 9 | 14 | 65.4 | |

300*150 | 6.5 | 9 | 36.7 | 37.3 |

294*200 | 8 | 12 | 55.8 | 57.3 |

300*300 | 10 | 15 | 93 | 94.5 |

346*174 | 6 | 9 | 41.2 | 41.8 |

350*175 | 7 | 11 | 49.4 | 50 |

340*250 | 9 | 14 | 78.1 | 79.7 |

350*350 | 12 | 19 | 135 | 137 |

400*200 | 8 | 13 | 65.4 | 66 |

390*300 | 10 | 16 | 105 | 107 |

400*400 | 13 | 21 | 172 | 172 |

446*199 | 8 | 12 | 65.1 | 66.7 |

450*200 | 9 | 14 | 77.9 | 79.5 |

440*300 | 11 | 18 | 121 | 124 |

496*199 | 9 | 14 | 77.9 | 79.5 |

500*200 | 10 | 16 | 88.2 | 89.6 |

488*300 | 11 | 18 | 125 | 129 |

596*199 | 10 | 15 | 92.5 | 95.1 |

600*200 | 11 | 17 | 103.4 | 106 |

588*300 | 12 | 20 | 147 | 151 |

700*300 | 13 | 24 | 182 | 185 |

800*300 | 14 | 26 | 207 | 210 |

900*300 | 16 | 28 | 240.1 | 243 |

Usage & Applications of Hot Rolled Steel H-beam For Sale

Commercial building structure ;Pre-engineered buildings; Machinery support structure; Prefabricated structure; Medium scale bridges; Ship-building structure.etc.

Packaging & Delivery of Hot Rolled Steel H-beam For Sale

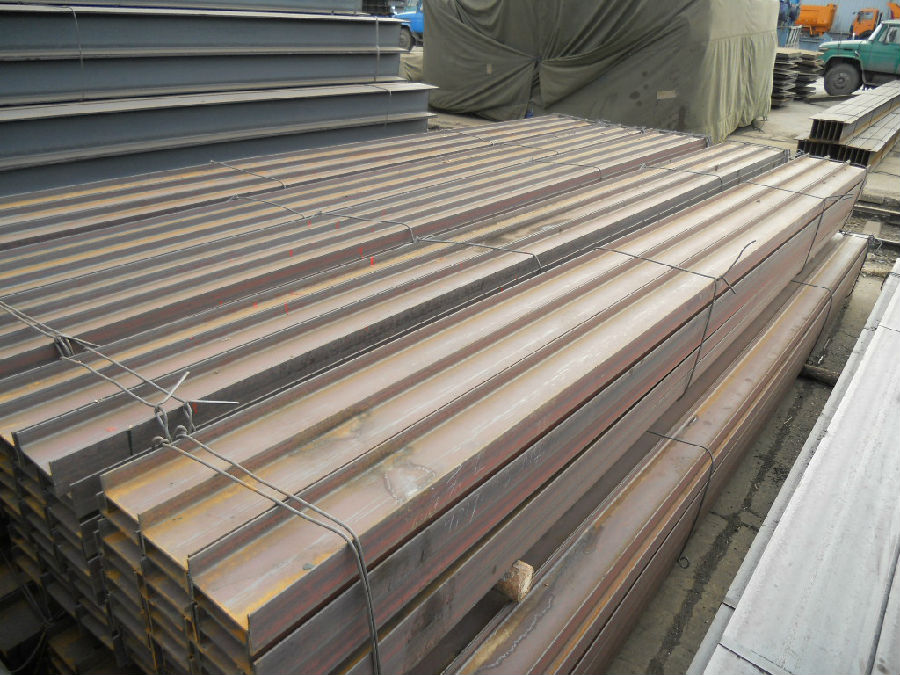

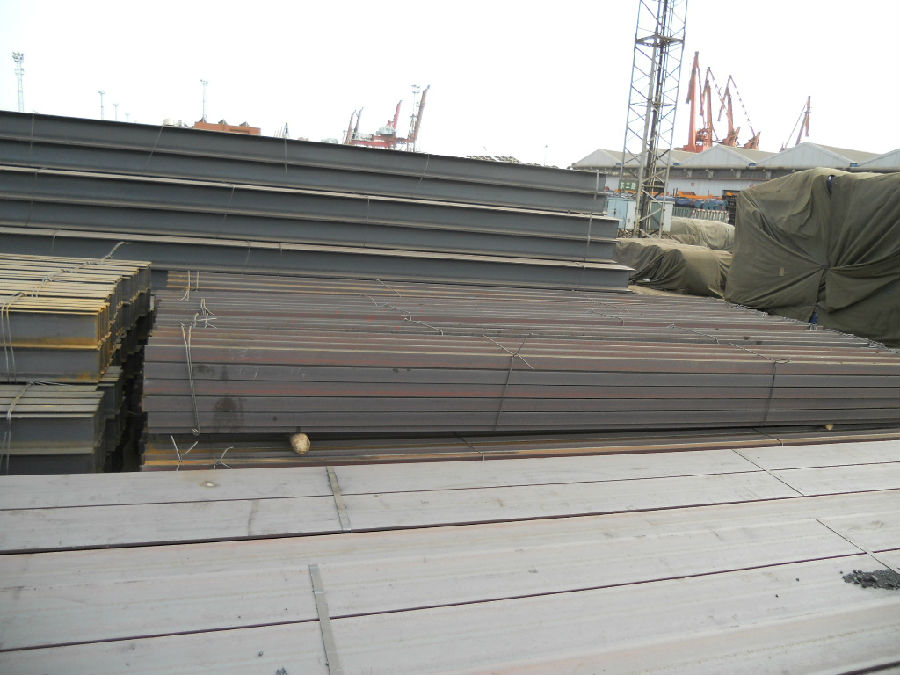

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

- Q: How do steel H-beams perform in terms of thermal insulation?

- Steel H-beams do not perform well in terms of thermal insulation. Steel is a good conductor of heat, meaning it easily allows heat to pass through it. As a result, steel H-beams can contribute to heat loss or gain in a building, making them less effective in providing thermal insulation compared to materials with better insulating properties, such as wood or insulation materials.

- Q: What are the different methods of lifting and installing steel H-beams?

- Various methods can be utilized to lift and install steel H-beams, depending on project requirements and available equipment. Some commonly employed techniques include: 1. Crane: The prevailing and extensively utilized approach involves deploying a crane to hoist and place H-beams. Cranes of different sizes and capacities allow for efficient and precise beam positioning at the desired location. Depending on the beam's dimensions and weight, mobile cranes or tower cranes may be employed. 2. Forklift or telehandler: For smaller and lighter H-beams, a forklift or telehandler can be employed. These machines possess adjustable forks or lifting attachments that can accommodate the beam's width. They offer a flexible and cost-effective solution for lifting and installing beams in compact areas or on uneven surfaces. 3. Hydraulic jacking system: In situations with limited access or overhead clearance, a hydraulic jacking system can be utilized. This method entails incrementally raising the beam using hydraulic jacks and inserting shims or temporary supports until the desired height is attained. The process is repeated until the beam is correctly installed. 4. Skidding or rolling: This technique is suitable for lengthy H-beams or instances where a crane is unavailable. It involves gradually moving the beam horizontally into position using rollers or skids. This method necessitates meticulous planning and precise coordination to ensure proper alignment during installation. 5. Welding or bolting: Once the H-beams are lifted and in position, they must be secured to the supporting structure. This can be achieved through welding or bolting, depending on the structural requirements and design specifications. Welding provides a durable connection, whereas bolting allows for easy disassembly if needed. It is crucial to adhere to proper safety measures when lifting and installing steel H-beams. This includes ensuring equipment is in good working condition, using suitable slings, chains, or lifting devices, and adhering to relevant safety guidelines and regulations. Additionally, the chosen method will depend on factors such as beam size and weight, site conditions, and project constraints.

- Q: Can steel H-beams be used in marine environments?

- Yes, steel H-beams can be used in marine environments, but they require proper protection and maintenance to prevent corrosion. Marine environments are known for their high levels of moisture, saltwater exposure, and harsh weather conditions, all of which can accelerate the corrosion process of steel. To mitigate these risks, steel H-beams used in marine environments should be made from corrosion-resistant materials, such as stainless steel or galvanized steel. Stainless steel is especially suitable for marine environments due to its high resistance to corrosion and rust. It contains a significant amount of chromium, which forms a thin, passive layer on the surface of the steel, protecting it from the corrosive effects of saltwater and moisture. Stainless steel H-beams can withstand the harsh marine environment without significant degradation, making them a popular choice for applications such as piers, bridges, and offshore structures. Galvanized steel is another viable option for marine environments. It is carbon steel that has been coated with a layer of zinc, which acts as a sacrificial barrier against corrosion. The zinc coating corrodes first, protecting the underlying steel from direct exposure to saltwater and moisture. However, galvanized steel may not be as durable as stainless steel in highly corrosive marine environments, and the protective zinc coating can wear off over time, requiring periodic maintenance and reapplication of the coating. Regardless of the type of steel used, regular maintenance and inspections are crucial to ensure the integrity of H-beams in marine environments. This includes regular cleaning to remove salt deposits, repainting or re-galvanizing as needed, and addressing any signs of corrosion or damage promptly. Additionally, proper design considerations should be made to account for the specific challenges posed by marine environments, such as tidal forces, wave impact, and temperature fluctuations. In summary, steel H-beams can be used in marine environments, provided they are made from corrosion-resistant materials like stainless steel or galvanized steel and are properly maintained. With the right precautions, these beams can withstand the harsh conditions of marine environments, making them a reliable choice for various marine structures and applications.

- Q: Can steel H-beams be used for healthcare facilities or hospitals?

- Yes, steel H-beams can be used for healthcare facilities or hospitals. Steel H-beams are commonly used in construction due to their strength, durability, and ability to support heavy loads. In healthcare facilities or hospitals, steel H-beams can be used in various applications, such as providing structural support for the building, creating partitions or walls, supporting overhead equipment, or even constructing specialized features like surgical theaters or MRI rooms. The versatility of steel H-beams allows for flexible and efficient design options to meet the specific needs of healthcare facilities or hospitals, ensuring the safety and stability of the structures. Additionally, steel is a non-combustible material, which adds an extra layer of safety and meets the stringent fire safety regulations often required in healthcare settings. Overall, steel H-beams offer a reliable and practical solution for construction in healthcare facilities or hospitals.

- Q: What is the cost of steel H-beams?

- The cost of steel H-beams can vary depending on various factors such as the size, length, and quality of the beams. Generally, the price range for steel H-beams can start from around $200 per ton and go up to several thousand dollars per ton. It is important to note that prices can also vary based on market conditions, location, and supplier. Therefore, it is recommended to contact local steel suppliers or check online platforms to get accurate and up-to-date pricing information for steel H-beams.

- Q: Can steel H-beams be used in sports arena structures?

- Yes, steel H-beams can be used in sports arena structures. Steel H-beams are commonly used in construction due to their strength, durability, and versatility. They provide excellent structural support and can withstand heavy loads, making them suitable for large-scale projects like sports arenas.

- Q: What does H steel.R represent?

- It should mean the rounded radius of H steel.

- Q: Are Steel H-Beams suitable for art or cultural facility construction?

- Yes, Steel H-Beams are suitable for art or cultural facility construction. Steel H-Beams are widely used in construction due to their strength and durability. They provide excellent support and stability, making them ideal for large-scale structures such as art galleries, museums, and cultural facilities. Additionally, Steel H-Beams can be easily fabricated and customized to meet specific design requirements, allowing for flexibility and creativity in the construction of art and cultural spaces. Their versatility, combined with their ability to withstand heavy loads and resist natural elements, makes Steel H-Beams a reliable choice for constructing art and cultural facilities.

- Q: Can steel H-beams be used in the construction of recreational centers or gyms?

- Indeed, recreational centers or gyms can utilize steel H-beams in their construction. These beams, widely employed in the construction sector, are renowned for their structural resilience and endurance. They possess exceptional load-bearing capabilities, thus making them ideal for supporting extensive spans and hefty loads commonly encountered in recreational centers or gyms. Moreover, the fabrication and assembly of steel H-beams are both effortless and expedient, permitting efficient construction and adaptability in design. By incorporating steel H-beams into the construction of recreational centers or gyms, a sturdy and enduring structure is guaranteed, capable of withstanding the rigorous demands of such facilities.

- Q: What are the dimensions of a standard steel H-beam?

- The dimensions of a standard steel H-beam can vary depending on the specific design and manufacturer. However, there are commonly used dimensions for standard steel H-beams. These beams typically have a width or flange that ranges from 100 millimeters to 900 millimeters, a height or web that ranges from 100 millimeters to 300 millimeters, and a thickness or weight per meter that ranges from 17 kilograms to 166 kilograms. It is important to note that these dimensions can be subject to variations and specific requirements based on the intended use and load-bearing capacity of the H-beam.

Send your message to us

Hot Rolled JIS Standard H-beam Steel Bar

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords