Hot Rolled Galvanized Construction Deformed Twisted Steel Rebar

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 180 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

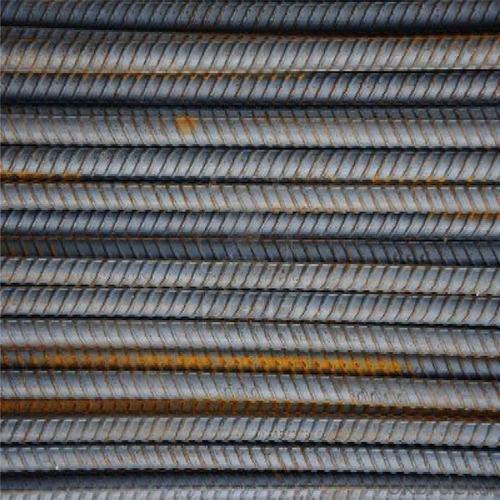

Hot Rolled Galvanized Construction Deformed Twisted Steel Rebar

Description of Hot Rolled Galvanized Construction Deformed Twisted Steel Rebar

1, Diameter: 5.5mm-10mm Reinforced Steel Bar Hrb400B

10m- 40mm Reinforced Steel Bar Hrb400B

2, Length: 6m, 9m, 12m or customized

3, Standard: GB, ASTM, AISI, SAE, DIN, JIS, EN

OEM technology - send detailed technical parameters for accurate quotation.

2, Produce Process: smelt iron - EAF smelt billet - ESR smelt billet -

hot rolled or forged to get the steel round bar and plate

3, Heat Treatment: annealing, normalizing, tempering, quenching

4, Surface Treatment: Black

5, Quality Assurance: We accept third party inspection for all orders.

You can ask testing organizations such as SGS, BV, etc. to test our products before shipping.

Chemical Composition of Hot Rolled Galvanized Construction Deformed Twisted Steel Rebar

Grade | Technical data of the original chemical composition(%) | |||||

Reinforcing steel bar HRB335 | C | Mn | Si | S | P | B |

≤0.25 | ≤1.60 | ≤0.80 | ≤0.045 | ≤0.045 | >0.0008 | |

Physics Capability | ||||||

Yield Strength(N/cm2) | Tensile Strength(N/cm2) | Elongation(%) | ||||

≥ 335 | ≥490 | ≥16 | ||||

Reinforcing steel bar HRB400 | C | Mn | Si | S | P | B |

≤0.25 | ≤0.16 | ≤0.80 | ≤0.045 | ≤0.045 | 0.04-0.12 | |

Physics Capability | ||||||

Yield Strength(N/cm2) | Tensile Strength(N/cm2) | Elongation(%) | ||||

≥ 400 | ≥ 570 | ≥ 14 | ||||

Products Show of Hot Rolled Galvanized Construction Deformed Twisted Steel Rebar

Company Information

CNBM International Corporation is the most important trading platform of CNBM group.

Whith its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high qulity series of refractories as well as technical consultancies and logistics solutions.

F A Q

1, Your advantages?

professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposale

2, Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3, Factory or Trading Company?

CNBM is a trading company but we have so many protocol factories and CNBM works as a trading department of these factories. Also CNBM is the holding company of many factories.

4, Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

5, Trading Terms?

EXW, FOB, CIF, FFR, CNF

6, After-sale Service?

CNBM provides the services and support you need for every step of our cooperation. We're the business partner you can trust.

For any problem, please kindly contact us at any your convenient time.

We'll reply you in our first priority within 24 hours.

- Q: What are the properties of wear-resistant stainless steel?

- Wear-resistant stainless steel possesses several key properties that make it a highly durable and reliable material. Firstly, it has a high hardness level, which helps it withstand abrasion and wear caused by friction. Secondly, it exhibits excellent corrosion resistance, protecting it from rust and other forms of degradation. Additionally, wear-resistant stainless steel has a high tensile strength, allowing it to withstand heavy loads and impacts without deforming or breaking. Lastly, it maintains its properties at elevated temperatures, making it suitable for use in high-temperature environments. Overall, these properties make wear-resistant stainless steel an ideal choice for applications that require strength, durability, and resistance to wear and corrosion.

- Q: Can special steel be used in the chemical processing industry?

- Yes, special steel can be used in the chemical processing industry. Special steel alloys, such as stainless steel, offer excellent corrosion resistance and high strength, making them suitable for various applications in chemical plants. These steels can withstand the harsh conditions, chemicals, and high temperatures typically encountered in chemical processing, ensuring the safety and efficiency of the operations.

- Q: What are the main applications of special steel in the power generation equipment?

- Special steel is widely used in power generation equipment due to its exceptional properties such as high strength, corrosion resistance, and heat resistance. It finds applications in various components of power generation equipment, including turbine blades, boiler tubes, heat exchangers, and pressure vessels. These components need to withstand extreme conditions such as high temperatures, pressures, and corrosive environments. Special steel ensures the durability and reliability of power generation equipment, ultimately enhancing the efficiency and performance of power plants.

- Q: What are the challenges in machining high-speed special steel?

- Several challenges arise when machining high-speed special steel due to its unique properties and characteristics. Its extreme hardness presents one of the main obstacles, making cutting and shaping difficult. High-speed special steel typically has a high carbon content and undergoes heat treatment to enhance its hardness, resulting in increased wear on cutting tools. The increased hardness of this steel also leads to elevated heat generation during the machining process. This heat can cause thermal distortion and impact the dimensional accuracy of the final product. To counteract this, specialized cooling techniques and cutting tools with advanced coatings must be used to dissipate heat and maintain stability. Another challenge is the brittleness of high-speed special steel. It tends to have low toughness and is susceptible to cracking and chipping during machining operations. To minimize the risk of tool failure and excessive stress, careful selection of cutting parameters such as cutting speed, feed rate, and depth of cut is necessary. Furthermore, high-speed special steel often contains alloying elements like tungsten, vanadium, and cobalt, which can further complicate the machining process. While these elements increase the strength and wear resistance of the steel, they also make it more challenging to machine. Effective machining of these alloys and achieving desired surface finishes requires specialized tool materials and cutting strategies. Additionally, the cost of high-speed special steel is often significantly higher than that of conventional steels, adding to the challenges of machining. The high tooling costs associated with the cutting tools required for machining this steel can be a substantial investment. Overall, machining high-speed special steel necessitates advanced cutting techniques, specialized tooling, and careful consideration of cutting parameters to overcome the challenges posed by its extreme hardness, brittleness, and alloying elements.

- Q: What are the different methods of surface shot blasting for special steel?

- There are several different methods of surface shot blasting that can be used for special steel. Some of the most common methods include: 1. Wheel blasting: This method involves using a wheel with abrasive particles to blast the surface of the special steel. The wheel spins rapidly and throws the abrasive particles onto the steel, removing any contaminants or imperfections. 2. Air blasting: In this method, compressed air is used to propel abrasive particles onto the surface of the special steel. The high-speed impact of the particles helps to clean and prepare the surface for further treatment or coating. 3. Wet blasting: This technique involves mixing abrasive particles with water and then spraying the mixture onto the surface of the special steel. The water helps to control the dust and heat generated during the blasting process, making it suitable for sensitive or delicate steel surfaces. 4. Vacuum blasting: Vacuum blasting combines the use of abrasive particles with a vacuum system to remove both the particles and the contaminants from the surface of the special steel. This method is particularly useful for removing paint or coatings from the steel. 5. Shot peening: Shot peening is a specialized form of shot blasting that is used to enhance the strength and fatigue resistance of the special steel. It involves bombarding the surface with small spherical particles, which create compressive stresses that improve the steel's durability. Each of these methods has its own advantages and is suitable for different types of special steel and surface conditions. The choice of method will depend on factors such as the desired surface finish, the level of contamination, and the specific requirements of the steel application.

- Q: What are the main factors affecting the creep rupture strength of special steel?

- The main factors affecting the creep rupture strength of special steel can be categorized into several key parameters. 1. Temperature: Creep rupture strength is highly dependent on the temperature at which the steel is operating. Higher temperatures can significantly reduce the creep rupture strength of special steel due to the increased atomic diffusion and dislocation movement, leading to accelerated deformation and eventual failure. 2. Time: Creep rupture strength is also influenced by the time duration of the applied load. Creep is a time-dependent phenomenon, meaning that the longer the steel is subjected to stress, the more likely it is to experience rupture. The relationship between time and creep rupture strength is typically described by a power law equation, where longer durations result in lower rupture strength. 3. Stress Level: The applied stress level is a critical factor affecting creep rupture strength. Higher levels of stress can cause faster deformation and reduce the time to rupture. Therefore, it is important to ensure that the stress level applied to special steel is within the acceptable range to maintain its desired creep rupture strength. 4. Microstructure: The microstructure of special steel plays a crucial role in determining its creep rupture strength. Factors such as grain size, grain boundary characteristics, and the presence of alloying elements can all influence the steel's resistance to creep deformation and rupture. Fine-grained microstructures with a high density of grain boundaries tend to exhibit better creep resistance and higher rupture strength. 5. Composition: The chemical composition of special steel can significantly impact its creep rupture strength. The addition of certain alloying elements, such as chromium, molybdenum, and vanadium, can enhance the steel's high-temperature strength and resistance to creep deformation. These elements form stable carbides, which impede the movement of dislocations and improve the material's creep rupture strength. 6. Heat Treatment: The heat treatment process used to modify the microstructure of special steel can also affect its creep rupture strength. Proper heat treatment can optimize the grain size, distribution of alloying elements, and overall microstructure, resulting in improved creep resistance and higher rupture strength. Overall, the main factors affecting the creep rupture strength of special steel include temperature, time, stress level, microstructure, composition, and heat treatment. Understanding and controlling these parameters is crucial in ensuring the desired performance and reliability of special steel in high-temperature and long-term applications.

- Q: Can special steel be used in the beverage manufacturing industry?

- Yes, special steel can be used in the beverage manufacturing industry. Special steel, such as stainless steel, is commonly used in beverage processing equipment due to its corrosion resistance, hygienic properties, and durability. It is particularly suitable for manufacturing tanks, pipes, valves, and other components that come into contact with beverages, ensuring a high level of safety and maintaining the quality of the products.

- Q: How does special steel respond to welding?

- Alloy steel, also known as special steel, possesses distinct characteristics that impact its welding response. Unlike regular carbon steel, special steel incorporates additional alloying elements like chromium, nickel, or molybdenum, which augment its strength, resistance to corrosion, and heat endurance. In terms of welding, special steel generally exhibits favorable behavior due to its elevated tensile strength and toughness. However, a few considerations should be borne in mind. The elevated carbon content in certain special steels can result in cracking or brittleness during the welding process. To prevent this, preheating the material and employing appropriate welding techniques are imperative. Selecting the appropriate welding method based on the specific type of special steel being utilized is crucial. For example, gas tungsten arc welding (GTAW) or tungsten inert gas (TIG) welding is commonly favored for welding stainless steel due to its ability to precisely control heat input and produce high-quality welds with minimal distortion. Additionally, special steel often necessitates the use of specialized welding consumables, like electrodes or filler wires, specifically formulated for the particular alloy composition. These consumables aid in maintaining the desired mechanical properties and preventing the formation of brittle phases in the weld. Post-weld heat treatment is also vital for certain special steels as it alleviates residual stresses and enhances the overall properties of the weldment. This process can involve annealing, normalizing, or tempering, depending on the specific steel grade and application requirements. In conclusion, special steel responds favorably to welding, but it is crucial to consider its alloy composition, carbon content, and specific welding techniques. By adhering to proper welding procedures, employing appropriate consumables, and implementing necessary heat treatments, high-quality welds can be achieved, guaranteeing the integrity and performance of the special steel components.

- Q: Are there any disadvantages of using special steel?

- Yes, there are a few disadvantages to using special steel. Firstly, special steel is typically more expensive than regular steel due to its unique composition and properties. This can make it less accessible or viable for certain projects with budget constraints. Additionally, special steel often requires specialized knowledge and expertise for its proper handling and processing, which may limit its use to industries or professionals with the necessary skills. Finally, the specific characteristics of special steel, such as high strength or corrosion resistance, may not be required for every application, leading to unnecessary costs or over-engineering in certain cases.

- Q: How does special steel compare to other high-performance materials?

- Special steel stands out from other high-performance materials due to its exceptional strength, durability, and versatility. It exhibits higher tensile strength compared to materials like aluminum, titanium, and composites, making it suitable for robust and load-bearing applications. Moreover, special steel excels in resisting corrosion, heat, and wear, making it a perfect choice for harsh environments and high-temperature uses. One advantage of special steel is its cost-effectiveness, making it more affordable than materials like titanium. This affordability makes it the preferred choice in various industries. Additionally, the manufacturing process allows for customization, enabling the production of different grades and compositions to meet specific requirements. Special steel's excellent machinability and weldability make fabrication and assembly easy. Its versatility allows it to be utilized in various industries, including automotive, aerospace, construction, and energy. Whether it's structural components or precision tools, special steel provides a reliable and efficient solution. However, it's important to consider that the choice of material depends on the specific application and its requirements. While special steel has numerous advantages, there may be instances where other high-performance materials are more suitable, such as lightweight components or extreme temperature conditions. Therefore, conducting a comprehensive evaluation of the application's needs and characteristics is crucial in determining the most appropriate material.

Send your message to us

Hot Rolled Galvanized Construction Deformed Twisted Steel Rebar

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 180 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords