Hot Rolled Deformed Steel Rebars for Buildings GB Standard

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Hot Rolled Deformed Steel Rebars for Buildings GB Standard at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Hot Rolled Deformed Steel Rebars for Buildings GB Standard are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

1. Supporting members, most commonly in the house raising industry to strengthen timber bears under houses. Transmission line towers, etc

2. Prefabricated structure

3. Medium scale bridges

4. It is widely used in various building structures and engineering structures such as roof beams, bridges, transmission towers, hoisting machinery and transport machinery, ships, industrial furnaces, reaction tower, container frame and warehouse etc.

Product Advantages:

Hot Rolled Deformed Steel Rebars for Buildings GB Standard are durable, strong, and resist corrosion. And they are made of steel billets of high quality of China.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Specifications:

Specifications of Hot Rolled Deformed Steel Rebars for Buildings GB Standard:

Standard | GB UK USA | HRB335 HRB400 HRB500 G460B, B500A, B500B,B500C GR40, GR60 | |

Diameter | 6mm,8mm,10mm,12mm,14mm,16mm,18mm,20mm, 22mm,25mm,28mm,32mm,36mm,40mm,50mm | ||

Length | 6M, 9M,12M or as required | ||

Packing | Export standard packing: wrapped by wire rod in bundles | ||

Each bundle weight | 2-3MT, or as required | ||

Trade terms | FOB, CFR, CIF | ||

Payment terms | TT payment in advance or Irrevocable LC at sight. | ||

Delivery Detail | within 45 days after received advanced payment or LC. | ||

Brand name | DRAGON | ||

Theoretical weight and section area of each diameter as below for your information:

Diameter(mm) | Section area (mm²) | Mass(kg/m) | Weight of 12m (kg) | Pcs/ton |

6 | 28.27 | 0.222 | 2.664 | 375.38 |

8 | 50.27 | 0.395 | 4.74 | 210.97 |

10 | 78.54 | 0.617 | 7.404 | 135.06 |

12 | 113.1 | 0.888 | 10.656 | 93.84 |

14 | 153.9 | 1.21 | 14.52 | 68.87 |

16 | 201.1 | 1.58 | 18.96 | 52.74 |

18 | 254.5 | 2.00 | 24 | 41.67 |

20 | 314.2 | 2.47 | 29.64 | 33.74 |

22 | 380.1 | 2.98 | 35.76 | 27.96 |

25 | 490.9 | 3.85 | 46.2 | 21.65 |

28 | 615.8 | 4.83 | 57.96 | 17.25 |

32 | 804.2 | 6.31 | 75.72 | 13.21 |

36 | 1018 | 7.99 | 98.88 | 10.43 |

40 | 1257 | 9.87 | 118.44 | 8.44 |

50 | 1964 | 15.42 | 185.04 | 5.40 |

Chemical Composition: (Please kindly find our chemistry of our material based on JIS as below for your information)

JISG3112 SD390 | Chemical Composition | ||||

C | Mn | Si | S | P | |

0.22 | 1.38 | 0.4 | 0.014 | 0.022 | |

Physical capability | |||||

Yield Strength(N/cm²) | Tensile Strength(N/cm²) | Elongation (%) | |||

620 | ≥400 | 21 | |||

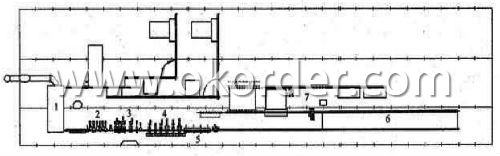

The production process of Steel Rebar

1-Waling beam furnace 2-Roughing rolling group 3-Intermediate rolling train

4-Finishing rolling group 5-Water-cooling device 6-Walking beam cooler

7-Finishing equipment(including the cold scale shear,short feet collection system,

automatic counting device,bundling machine, collect bench)

Usage and Applications of Hot Rolled Deformed Steel Rebars for Buildings GB Standard:

Hot Rolled Deformed Steel Rebars for Buildings GB Standard is widely used in buildings, bridges, roads and other engineering construction. Big to highways, railways, bridges, culverts, tunnels, public facilities such as flood control, dam, small to housing construction, beam, column, wall and the foundation of the plate, deformed bar is an integral structure material. With the development of world economy and the vigorous development of infrastructure construction, real estate, the demand for deformed bar will be larger and larger..

Packaging & Delivery of Hot Rolled Deformed Steel Rebars for Buildings GB Standard:

Packaging Detail: products are packed in bundle and then shipped by container or bulk vessel, deformed bar is usually naked strapping delivery, when storing, please pay attention to moisture proof. The performance of rust will produce adverse effect.

Price: Keep lower operating costs so as to offer competitive price for our clients

Deformed Steel Rebars according to Korean standard

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

- Q: Can steel rebars be used in structures with high vibrations?

- Yes, steel rebars can be used in structures with high vibrations. Steel rebars are commonly used in construction due to their high tensile strength and ability to withstand various forces, including vibrations. However, it is important to consider the specific requirements and design parameters of the structure to ensure that the rebars are properly anchored and reinforced to withstand the anticipated vibrations.

- Q: How do steel rebars affect the thermal conductivity of concrete structures?

- Steel rebars have a significant impact on the thermal conductivity of concrete structures. The inclusion of steel rebars in concrete increases the overall thermal conductivity of the structure. This is because steel has a much higher thermal conductivity than concrete. Consequently, heat transfer through the concrete is facilitated by the presence of steel rebars, leading to a higher overall thermal conductivity of the structure.

- Q: How can steel rebars be recycled after their service life?

- Steel rebars can be recycled after their service life through a process called steel scrap recycling. This involves collecting the used steel rebars, sorting them, and then melting them down in a furnace. The molten steel is then shaped into new rebars or other steel products. This recycling process not only helps reduce the demand for raw materials but also minimizes waste and environmental impact.

- Q: How do steel rebars affect the overall durability of concrete?

- Steel rebars have a significant impact on the overall durability of concrete structures. The presence of steel rebars in concrete enhances its strength and resistance to various external forces and environmental conditions. One of the primary functions of steel rebars is to provide tensile strength to concrete, which is otherwise weak in resisting tension. Concrete is excellent in compression but tends to crack under tension. By embedding steel rebars within the concrete, these cracks are effectively controlled and prevented from expanding, thus improving the durability of the structure. Steel rebars also help in increasing the flexural strength of concrete, making it more capable of withstanding bending and deformations. This is particularly crucial in structures such as beams, columns, and slabs that experience significant loads and forces during their lifespan. Moreover, steel rebars act as a reinforcement in concrete, improving its resistance to external factors such as earthquakes, wind, and impact loads. The presence of rebars helps in distributing and dissipating these forces throughout the structure, reducing the chances of structural failure and increasing the overall durability. Another critical aspect is the prevention of corrosion in reinforced concrete structures. The steel rebars are typically coated with materials that protect them from corrosion caused by moisture and chemical reactions. This protective coating, coupled with the alkaline environment of concrete, creates a barrier that significantly slows down the corrosion process, thereby increasing the longevity and durability of the concrete structure. In conclusion, steel rebars play a vital role in enhancing the overall durability of concrete structures. They provide the necessary tensile strength, improve flexural strength, enhance resistance to external forces, and prevent corrosion. By incorporating steel rebars, concrete becomes more robust, long-lasting, and capable of withstanding various challenges, ensuring the longevity and safety of the structure.

- Q: How are steel rebars transported and stored on construction sites?

- Trucks or trailers are typically used to transport steel rebars to construction sites. These vehicles are specifically designed to safely carry and unload the heavy and bulky rebars. When the rebars arrive at the site, they are usually offloaded using cranes or forklifts. To make storage and access more efficient, rebars are often kept in designated areas known as rebar yards. These yards are typically organized in a manner that allows for easy identification and retrieval of rebars when needed. The rebars are sorted and stacked according to their size, length, and type to avoid any confusion during construction. In the rebar yard, rebars are commonly stored horizontally on racks made of steel or wood. These racks are designed to provide proper support and prevent any damage to the rebars. It's important to note that rebars should be stored above ground level to protect them from moisture, rust, and contamination. They should also be kept away from damp areas and direct contact with soil. To maintain the quality of the rebars, it's crucial to protect them from rain, snow, and excessive sunlight. Therefore, construction sites often utilize protective covers like tarps or plastic sheets to shield the rebars and prevent any corrosion or deterioration. Additionally, construction workers must handle rebars with care to avoid bending or deformation. Special attention should be paid to prevent dropping or dragging of rebars, as it can compromise their structural integrity. Overall, careful planning and adherence to safety guidelines are necessary for the transportation and storage of steel rebars on construction sites. This ensures the rebars maintain their quality and effectiveness in reinforcing concrete structures.

- Q: What is the role of steel rebars in preventing structural vibrations?

- The role of steel rebars in preventing structural vibrations is to provide reinforcement and increase the stiffness of concrete structures. Steel rebars are embedded within the concrete, forming a skeletal framework that enhances the structural integrity and reduces the risk of vibrations. When a load or force is applied to a structure, such as wind or seismic activity, it can cause the structure to vibrate. These vibrations can lead to structural damage or even collapse if left unchecked. Steel rebars help mitigate these vibrations by absorbing and distributing the forces throughout the structure. By reinforcing the concrete, steel rebars increase the stiffness and strength of the structure, thereby reducing the amplitude of vibrations. They help to resist bending and torsional forces, ensuring that the structure remains stable and secure under various load conditions. Furthermore, steel rebars also play a crucial role in preventing progressive collapse. In the event of localized damage or failure, the rebars act as a safety net, redistributing the load and preventing a complete collapse. This is particularly important in high-rise buildings or structures with complex geometries, where the consequences of structural failure can be catastrophic. Overall, the presence of steel rebars in concrete structures significantly enhances their ability to withstand vibrations and external forces, ensuring the safety and longevity of the structure.

- Q: What is the weight of a typical steel rebar?

- The size and length of a steel rebar can cause its weight to fluctuate. Nevertheless, a frequently employed size is the #4 rebar, boasting a 1/2 inch diameter. A #4 rebar usually carries a weight of approximately 0.67 pounds per foot or 9.5 pounds per 14-foot span. It is crucial to keep in mind that weights will vary for distinct sizes of steel rebar, thus necessitating consideration of the precise size and length in weight determination.

- Q: How are steel rebars protected against lightning strikes in buildings?

- Steel rebars in buildings are typically protected against lightning strikes by installing a lightning protection system, which includes lightning rods or air terminals strategically placed on the roof and connected to a network of conductors and grounding systems. This system helps to safely dissipate the electrical charge from a lightning strike, minimizing the risk of damage to the steel rebars and the overall structure.

- Q: Can steel rebars be used in the construction of high-speed rail tracks?

- Yes, steel rebars can be used in the construction of high-speed rail tracks. Steel rebars are commonly used as reinforcement in concrete structures, including railway tracks. They provide added strength and durability to the tracks, ensuring they can withstand the high speeds and heavy loads associated with high-speed rail systems.

- Q: What is the lifespan of steel rebars in concrete structures?

- The lifespan of steel rebars in concrete structures can vary due to a range of factors. Generally, steel rebars are designed to provide concrete structures with durability and strength. Through proper design, construction, and maintenance, steel rebars can endure for many decades or even up to a century within concrete structures. One crucial factor that affects the lifespan of steel rebars is the quality of materials utilized. Rebars of high quality, which have corrosion-resistant coatings or are made of stainless steel, tend to last longer compared to regular carbon steel rebars. Moreover, the quality of the concrete used and its ability to shield the rebars from moisture and corrosive agents is also significant. Environmental conditions play a significant role in determining the lifespan of steel rebars. Exposure to harsh climates, such as regions with high humidity, saltwater, or acidic environments, can expedite corrosion and reduce the lifespan of the rebars. Adequate protective measures, such as maintaining the proper thickness of concrete cover, implementing waterproofing techniques, and utilizing corrosion inhibitors, can help extend the lifespan of steel rebars in such conditions. Maintenance and inspection are essential to ensure the longevity of steel rebars in concrete structures. Regular inspections should be conducted to detect signs of corrosion, cracking, or damage, and any necessary repairs or protective measures should be promptly undertaken. In certain cases, periodic coating or replacement of rebars may be necessary to uphold the structural integrity of the concrete elements. In conclusion, the lifespan of steel rebars in concrete structures can range from several decades to over a century, depending on various factors including material quality, environmental conditions, and proper maintenance. By implementing appropriate design, construction, and maintenance practices, the lifespan of steel rebars can be significantly prolonged, guaranteeing the long-term integrity and durability of the concrete structure.

Send your message to us

Hot Rolled Deformed Steel Rebars for Buildings GB Standard

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords