Hot Rolled Carbon Steel Sheet CNBM

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 30 pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Quick Details

| Standard: | AISI, ASTM, DIN, GB, JIS | Grade: | A572,A573,A633,A678,A709,A710,G3101,G3136,etc | Thickness: | 1mm-200mm |

| Brand Name: | SHOU GANG GROUP, AN STEEL | Model Number: | Q235 | ||

| Type: | Steel Plate | Technique: | Hot Rolled | Surface Treatment: | Coated |

| Application: | widely | Special Use: | High-strength Steel Plate | Width: | 1000mm-3000mm |

| Length: | 1000mm-12000mm | Price Term: | FOB CIF CFR |

Packaging & Delivery

| Packaging Details: | standard seaworthy export packing or as the request of customers |

| Delivery Detail: | 10 days after deposit or according to customers' quantity |

Specifications

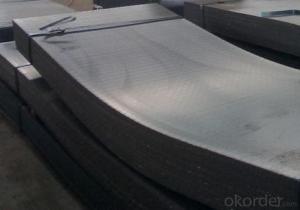

hot rolled carbon steel sheet

1.Thickness:1mm-200mm

2.Length:1000mm-12000mm

3.Width:1000mm-2000mm

hot rolled carbon steel sheet

| Product | HR steel plate prices carbon steel plate prices per kg |

| MOQ | 25 ton |

| Thickness | 1mm-200mm |

| Width | 1000mm-3000mm |

| Length | 1000mm-12000mm |

| Application | widely |

| Standard | AISI,ASTM,BS,DIN,JIS,GB,etc |

| Grade | A572,A573,A633,A678,A709,A710,G3101,G3136,etc |

| Tpye | Steel plate |

| Surfacing | Coated |

| Productive Technology | Hot Rolled & Cold Rolled |

| Port | |

| Payment Terms | L/C,T/T,Western Union,MoneyGram |

| Product Ability | 5000 tons per month |

| Delivery | 10 days after deposit or according to customers' quantity |

| Packing | standard seaworthy export packing or as the request of customers |

- Q: Are the steel sheets magnetic?

- Indeed, steel sheets possess magnetism. Being predominantly constituted of iron, steel qualifies as a ferromagnetic substance. Consequently, it can be subjected to magnetization and exhibit an attractive force towards other materials with magnetic properties. Steel sheets are frequently employed in contexts necessitating magnetic characteristics, such as the production of magnets, electrical devices, and diverse industrial machinery.

- Q: Can steel sheets be used for electrical applications?

- Yes, steel sheets can be used for certain electrical applications. Steel sheets are often used as a magnetic core material in transformers and in electrical motors. However, for most other electrical applications, materials with better electrical conductivity, such as copper or aluminum, are preferred.

- Q: How much is 2 millimeters per square meter?

- The performance of carbon steel mainly has the following deficiencies:(1) hardenability is low. Under normal circumstances, the maximum quenching diameter of carbon steel water quenching is only 10mm-20mm.(2) strength and yield strength are relatively low, such as the s of ordinary carbon steel Q235 is 235MPa, while that of low alloy structural steel 16Mn is 360MPa and above s. The sigma S / sigma B of steel 40 is only 0.43, much lower than that of alloy steel.(3) the stability of tempering tempering stability, carbon steel in quenching and tempering treatment, in order to ensure the high strength with the tempering temperature is lower, so the toughness of the steel is lower; in order to ensure good toughness, with high tempering temperature strength is low, the mechanical properties of carbon steel level is not high.(4) stainless steel can not meet the requirements of special performance. Carbon steel is often poor in oxidation resistance, corrosion resistance, heat resistance, low temperature resistance, wear resistance and special electromagnetic properties, and can not meet the needs of special performance.

- Q: Are steel sheets resistant to warping and twisting?

- Yes, steel sheets are highly resistant to warping and twisting due to their inherent strength and rigidity properties.

- Q: How do steel sheets handle electromagnetic interference?

- Steel sheets are highly effective in handling electromagnetic interference (EMI) due to their inherent electrical conductivity and magnetic permeability. These properties allow steel sheets to act as a shield against electromagnetic waves and prevent their penetration into or out of an enclosed space. When exposed to EMI, steel sheets act as a barrier, reflecting and absorbing electromagnetic waves, thus minimizing their impact on electronic devices and systems. This shielding effect is particularly crucial in sensitive environments such as data centers, laboratories, or industrial facilities where electromagnetic interference can disrupt electronic equipment and compromise their functionality. The thickness and composition of the steel sheet also play a significant role in determining its effectiveness in handling EMI. Thicker sheets provide better shielding due to increased attenuation of electromagnetic waves. Additionally, certain types of steel alloys, such as carbon steel or stainless steel, offer enhanced EMI shielding capabilities. It is important to note that while steel sheets provide excellent EMI shielding, they are not entirely impervious to electromagnetic waves. Factors such as the frequency of the waves and the size of any openings or gaps in the steel sheet can affect their shielding effectiveness. Therefore, proper installation and grounding techniques are essential to ensure optimal EMI protection. Overall, steel sheets are a reliable choice for managing electromagnetic interference, making them a preferred material in various industries where EMI shielding is critical for the uninterrupted operation of electronic devices and systems.

- Q: Can steel sheets be used in the telecommunications industry?

- Yes, steel sheets can be used in the telecommunications industry. Steel sheets are often used for constructing telecommunication towers and mast structures due to their strength, durability, and ability to withstand harsh weather conditions.

- Q: Are the steel sheets easy to maintain?

- Yes, steel sheets are easy to maintain. They require minimal upkeep, are resistant to corrosion, and can be easily cleaned with common household products.

- Q: Can steel sheets be used for solar panel manufacturing?

- Solar panel manufacturing can utilize steel sheets. Steel is a versatile material widely used in various industries, including renewable energy. It offers several advantages for manufacturing solar panels. To begin with, steel is a strong and durable material that provides structural integrity to solar panels. It can withstand harsh weather conditions and protect the delicate photovoltaic (PV) cells within the panels. This durability ensures longer lifespan for the panels, reducing maintenance and replacement costs. Additionally, steel sheets can be easily shaped and sized to meet the specific requirements of solar panel designs. This flexibility in manufacturing allows for the creation of efficient and visually appealing solar panels. Moreover, steel is a cost-effective option compared to alternatives such as aluminum or glass. It is readily available and has relatively low production costs, making it an economical choice for solar panel manufacturing. Nevertheless, it is important to note that steel sheets used in solar panel manufacturing are typically coated with protective layers to enhance their resistance to corrosion and prevent any negative impact on the PV cells. These coatings safeguard the steel from environmental factors like moisture or chemicals, ensuring the longevity and performance of the solar panels. In conclusion, steel sheets are indeed suitable for solar panel manufacturing due to their durability, versatility, cost-effectiveness, and ease of fabrication. When appropriately coated, steel provides a dependable and efficient solution for producing solar panels, thereby contributing to the growth of the renewable energy sector.

- Q: Are the steel sheets easy to install?

- Yes, steel sheets are generally easy to install. They are lightweight, making them easier to handle and maneuver during the installation process. Additionally, steel sheets often come with pre-drilled holes or interlocking systems, simplifying the installation further. With the appropriate tools and basic construction knowledge, individuals can easily install steel sheets on various surfaces such as roofs, walls, or fences. However, it's important to follow the manufacturer's instructions and safety guidelines to ensure a proper and secure installation.

- Q: How do steel sheets handle thermal conductivity?

- Steel sheets possess a relatively high level of thermal conductivity, which indicates their effectiveness in the transmission of heat. This characteristic enables steel to rapidly absorb and spread heat across its entirety. When subjected to a heat source, like a flame or hot object, steel sheets swiftly conduct the heat throughout their structure, resulting in consistent heating or cooling. Consequently, steel sheets are well-suited for applications demanding heat transfer, such as radiant heating systems in the construction industry or heat exchangers in manufacturing. The elevated thermal conductivity of steel also renders it a favored material for cookware, as it guarantees uniform heat distribution and efficient cooking. However, it is crucial to acknowledge that steel's thermal conductivity can also make it susceptible to heat loss in colder environments, necessitating appropriate insulation measures to uphold desired temperatures.

Send your message to us

Hot Rolled Carbon Steel Sheet CNBM

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 30 pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords