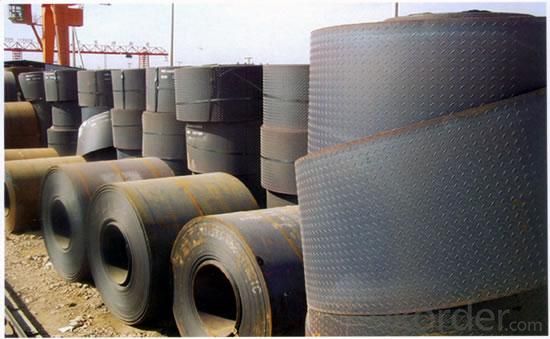

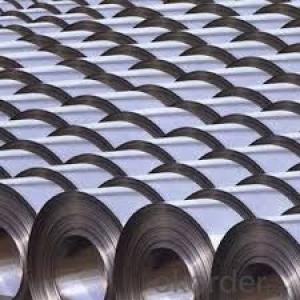

High grade hot rolling steel checkered plate

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The pattern shape

A tread surface plate is called a pattern plate, English Name: Diamond plate. The pattern of lentil shaped, diamond, round bean

Shape oblate shape, mixed, the market to the most common lentil shaped.

The specific application of

Pattern plate appearance, can slip, enhanced performance, and many other advantages,such as saving steel in transportation, construction, decoration, equipment around the floor,machinery, shipbuilding and other fields has been widely applied. In general, the use of side of the mechanics pattern plate performance, mechanical performance requirements is not high, so the pattern plate quality mainly flowering rate, as the pattern of pattern height, height difference. At present the common thickness on the market ranging from 2.0-8mm, the width of common 12501500mm two.

The relevant standards

In accordance with the provisions of national standards GB/T 3277 pattern plate, patternheight should be greater than or equal to the thickness of the 20% substrate.

Theoretical calculation of weight

Pattern plate, according to the material (aluminum alloy, stainless steel, ordinary steel etc.)different patterns of different shapes and different weight per square meter adjustment.

Class B common carbon steel rolling, the provisions of chemical composition meet the GB700"ordinary carbon structural steel technical conditions".

Pattern plate of high no less than 0.2 times the thickness of the substrate;

Checkered steel plate according to the weight of the actual weight of delivery or theory;

Mark example: made of Q235-A, size 4*1000*4000mm.

Peaberry pattern plate, mark it as: round bean plate Q235-A-4*1000*4000-GB/T 3277-91

Diamond pattern plate, mark it as: diamond pattern plate B 3-4*1000*4000-GB 3277-82

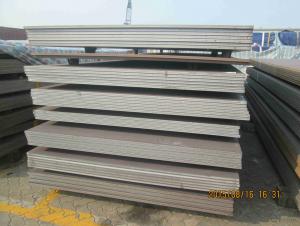

Steel with hot-rolled state of delivery;

Checkered steel plate surface without bubble, scar, crack, folding and inclusion, plate without delamination.

The surface quality is divided into two levels:

The general accuracy: steel surface with a thin layer of oxide scale and rust allowed, due to other local defects on the surface of oxide scale formed off rough and height or depthexceeds the allowable deviation of the ancient.

Burr height is not obvious and not more than the individual trace lines high allows patterns.The largest area of a single defect pattern with the square of the length of not more than.

High precision: steel surface with a thin layer of oxide scale, allowing the rust and the height or depth of no more than other local defects of half the thickness tolerance.

Pattern intact, a height of not more than half of the tolerance of thickness of the local slightburr allowed patterns.

- Q: Why can steel HPB300, steel plate without Q300, steel structure manuscript review, but also continued the Q235, why not improve it?

- HPB's full name is hot rolled round steel (HPB is Hot-rolled Plain Steel Bar) in English, commonly known as wire rod, diameter 6 - 12 rounds of the most common, including HPB235 and HPB300. You haven't met HPB400?. HRB400 and RRB400 are treated steel bars in order to have such high strength. But the general strength, ductility will be reduced, as the saying goes, "tossing" is not resistant to toss about.

- Q: Are steel sheets suitable for railway track construction?

- Yes, steel sheets are suitable for railway track construction. Steel is a highly durable and strong material, making it ideal for withstanding the heavy loads and constant traffic of trains. Steel sheets are often used as the base for railway tracks, providing a solid foundation for the rails and ensuring stability and reliability. Additionally, steel offers excellent resistance to wear, corrosion, and deformation, which are crucial factors in maintaining the long-term performance of railway tracks. Its high strength-to-weight ratio also allows for lighter track structures and reduced maintenance requirements. Overall, steel sheets are a popular choice in railway track construction due to their strength, durability, and cost-effectiveness.

- Q: Are the steel sheets resistant to chemicals?

- Yes, steel sheets are generally resistant to chemicals due to their inherent durability and corrosion-resistant properties. However, the specific resistance can vary depending on the type of chemical and the grade of steel used. It is advisable to consult with manufacturers or experts to determine the suitability of steel sheets for specific chemical applications.

- Q: What are the common tolerances for steel sheets?

- The common tolerances for steel sheets typically vary depending on the specific application and industry standards. However, some common tolerances for steel sheets include thickness variations, flatness, and width and length dimensions. These tolerances are often specified in accordance with recognized industry standards such as ASTM (American Society for Testing and Materials) or ISO (International Organization for Standardization).

- Q: What's the difference between hot-rolled seamless steel tube and cold-rolled seamless steel tube?

- Cold rolled seamless steel pipe (DIAL) in general, steel pipe for low and medium pressure boiler tube, high-pressure boiler steel pipe, alloy steel pipe, stainless steel pipe, oil cracking tube and other steel tube, including carbon thin-walled steel, alloy thin-walled steel, stainless steel, thin steel tube.

- Q: Are steel sheets suitable for decorative screens or partitions?

- Yes, steel sheets are suitable for decorative screens or partitions. They offer durability, strength, and a sleek aesthetic that can enhance the overall design of any space. Additionally, steel sheets can be customized with various patterns, textures, and finishes, allowing for endless creative possibilities in creating decorative screens or partitions.

- Q: What are the environmental impacts associated with steel sheet production?

- The environmental impacts associated with steel sheet production include emissions of greenhouse gases, such as carbon dioxide, during the manufacturing process. Additionally, the extraction of iron ore and other raw materials required for steel production can lead to habitat destruction and loss of biodiversity. Steel production also consumes significant amounts of water and energy, contributing to resource depletion and air pollution. Proper management of these impacts, including adoption of cleaner technologies and recycling, can help mitigate the environmental effects of steel sheet production.

- Q: Can steel sheets be used in the manufacturing of appliances?

- Yes, steel sheets can be used in the manufacturing of appliances. Steel is a commonly used material in appliance manufacturing due to its strength, durability, and resistance to corrosion. Steel sheets can be easily formed, cut, and welded to create various components and structures for appliances such as refrigerators, ovens, and washing machines.

- Q: What is the average cost of stainless steel sheets?

- The average cost of stainless steel sheets can vary depending on factors such as size, thickness, grade, and market conditions. However, as of 2021, the average cost ranges from $30 to $150 per square foot.

- Q: Can the steel surface be made of epoxy resin flooring?

- According to the characteristics of epoxy resin, it should be possible

Send your message to us

High grade hot rolling steel checkered plate

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords