Aluminum Sheets Weight Per Square Foot - Hot Rolled Aluminum Circles Disk for Cookware AA1100

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

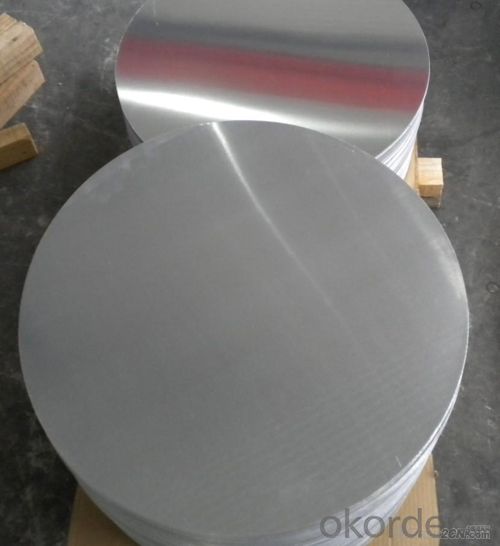

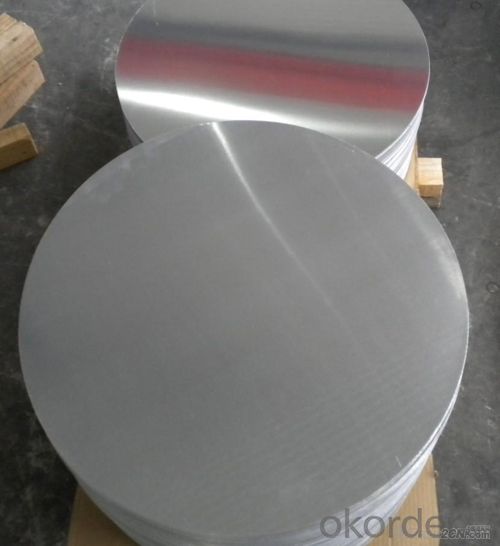

1.Description of Hot Rolled Aluminum Circles Disk for Cookware AA1100

Product: Aluminim Circle

Application: It is used in cookware, engineering, lighting purpose, fried pans, non-sticky pans, cooking pots, kettles, hard anodize cook wire, pressure cooker and house hold utensils, reflector of the light, etc

Advantage: Deep drawing and hard anodizing quality Aluminum Circle Sheet can be supplied. Our Aluminum Circle is RoHS and REACH compliance and uses well-protected packing. Our circles are excellent material for producing cookware, utensil, pots, pans and kettles.

2. Features of Hot Rolled Aluminum Circles Disk for Cookware AA1100

High manufacturing accuracy

Smooth surface

No waves

High strength of extension and yield

Well packaged

3. Pictures

4.Specifications of Hot Rolled Aluminum Circles Disk for Cookware AA1100

Alloy | AA1050,AA1060,AA1100 AA3003etc. |

Temper | O,H14 |

Thickness | 0.5MM-4MM |

Diagonal | 100-1200MM |

Standard | GB/T 3880-2006 |

5.FAQ

1) How about your company?

A world class manufacturer & supplier of aluminum coil and alloy blanks. Aluminum production base is comprised of 18 aluminum annealers, 10 coil and foil mills, 4 continuous production lines, 2 hot rolling production line and 3 prepainted lines.

Export 5000 tons per month to Asia, America and Middle East. Always do the best for our clients.

2) Can you guarantee the quality of the products?

We are responsible for the quality of materials to get a long-term cooperation with clients in a reasonable period of time and we are glad to arrange and coordinate any third party inspection for you.

3) What is the delivery time after purchase?

35 day after receiving client’s deposit or correct LC

- Q: what are the differences between aluminium , iron , steel.... properties like strength , durability , corrosion resistance properties...finally which is cost efficient and best for all purpose..??

- Brass is an alloy made of copper and zinc, and will show shades of yellow in it. Musical instruments are made from this as well as ornaments, military buttons etc. Bronze is made from copper and tin, and will appear browner in content. This allow is stronger than brass, and can be used for weapons, long lasting household items, etc.

- Q: what’s the difference of activated aluminum and aluminum sheet?

- you can use weak acid ,weak base solvent or steam to clean the oil and dirt on the surface, it's activated aluminum, their difference is that activated aluminum has porous structure oxide film.

- Q: What is the reflectivity of 101 aluminum sheets?

- The reflectivity of 101 aluminum sheets is typically high, as aluminum is known for its excellent reflective properties.

- Q: Can aluminum sheets be used for air ducts?

- Yes, aluminum sheets can be used for air ducts. Aluminum is a commonly used material for air ducts due to its lightweight and durable properties. It is resistant to corrosion, which makes it a suitable choice for HVAC systems. Aluminum sheets are often used to fabricate air ducts as they can be easily bent and shaped to fit the required dimensions. Additionally, aluminum has good thermal conductivity, allowing for efficient heat transfer within the ducts. Overall, using aluminum sheets for air ducts is a practical and effective choice.

- Q: What are the different types of alloys used for anodized aluminum sheets?

- There are several different types of alloys that can be used for anodized aluminum sheets, each with its own unique properties and applications. Some of the commonly used alloys include: 1. 1000 series alloys: These alloys are primarily made of pure aluminum and are known for their excellent corrosion resistance. They are commonly used for anodized aluminum sheets in various industries, including architecture, automotive, and aerospace. 2. 5000 series alloys: These alloys contain magnesium as the primary alloying element, which provides enhanced strength and excellent weldability. They are often used for anodized aluminum sheets in applications that require high strength and resistance to atmospheric corrosion. 3. 6000 series alloys: This series of alloys is known for its excellent combination of strength, extrudability, and corrosion resistance. The most commonly used alloy in this series for anodized aluminum sheets is 6061, which is widely used in structural components, marine applications, and consumer electronics. 4. 7000 series alloys: These alloys are known for their exceptional strength and are typically used in applications that require high-performance materials. The most common alloy in this series for anodized aluminum sheets is 7075, which is widely used in aerospace and defense industries. 5. 2000 series alloys: These alloys are primarily used in applications that require high strength and excellent fatigue resistance. They are commonly used in the aerospace industry for anodized aluminum sheets. It's important to note that the choice of alloy for anodized aluminum sheets depends on the specific requirements of the application, including desired strength, corrosion resistance, and other mechanical properties.

- Q: What type of aluminum plate does it contain?

- 1 * * * series aluminum sheet: stands for 1050, 1060, 1100. In all series, the 1 x x series belongs to a series with the largest amount of aluminum. Purity can reach more than 99%.2 * * * series aluminum sheet: 2A16 (LY16) and 2A06 (LY6). The characteristics of 2 * * * series of aluminum is high hardness, which belongs to the copper content is the highest, about 3-5%.

- Q: What are aluminum sheets?

- Aluminum sheets are thin, flat pieces of aluminum that are commonly used in various industries and applications. They are made from aluminum, which is a lightweight and versatile metal known for its exceptional strength, durability, and corrosion resistance. These sheets can range in thickness, width, and length, depending on the specific requirements of the project. Aluminum sheets are widely used in construction, automotive, aerospace, packaging, and manufacturing industries, among others. They are used for a multitude of purposes such as roofing, cladding, signage, transportation, electrical enclosures, and even household utensils. The flexibility and malleability of aluminum allow for easy shaping and forming, making it a popular choice for a wide range of applications. Additionally, aluminum sheets can be coated or finished to further enhance their appearance or protect them from external factors such as moisture, UV rays, or chemicals. Overall, aluminum sheets are essential materials that offer a combination of lightweight, strength, and corrosion resistance, making them ideal for various industrial and commercial uses.

- Q: Can the aluminum sheets be used for manufacturing food storage containers?

- Indeed, food storage containers can be manufactured using aluminum sheets. The utilization of aluminum in food storage containers is widespread due to its qualities such as being lightweight, long-lasting, and possessing exceptional thermal conductivity. Its malleability allows for effortless shaping into diverse dimensions, making it adaptable for various storage requirements. Moreover, aluminum exhibits resistance to corrosion and can be conveniently cleansed, guaranteeing the protection and cleanliness of the stored food.

- Q: Can aluminum sheets be used in automotive applications?

- Yes, aluminum sheets can be used in automotive applications. Aluminum is lightweight, corrosion-resistant, and has good strength-to-weight ratio, making it an ideal material for manufacturing automotive components such as body panels, engine parts, and structural components.

- Q: does anyone know how aluminum recycling works in term of redox reaction ( oxidizing, reduced, oxidizing agent, reducing agent?). how is that relate to the process of electrochemistry?

- Aluminum recycling is done by just melting the cans back into molten metal. There are reactions, but those deal with the impurities, not the aluminum. See the reference.

Send your message to us

Aluminum Sheets Weight Per Square Foot - Hot Rolled Aluminum Circles Disk for Cookware AA1100

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords