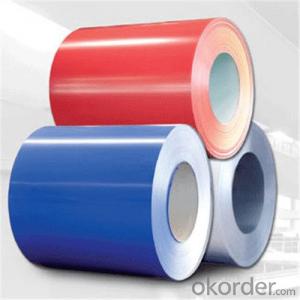

Hot Dipped Galvanized Strip/Hot Dipped Galvanized Steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Details

Basic Info.

Model NO.:0.12-1.5*10-1250mm

Standard:ASTM, JIS, GB, AISI, DIN, BS

Steel Grade:Q235

Certification:ISO, SGS, BV

Surface Treatment:Galvanized

Technique:Cold Rolled

Application:Flange Plate

Edge:Slit edge

Stock:Stock

Spangle:Large/Small/Minimized/Regular

Zinc Coating:60-275G/M2

Thickness:0.12-4.0

Width:20-600mm 600-1500mm

Coil ID:508mm/610mm

Base Materials:Cold/Hot Rolled Steel Coil

Surface:Chromated,Oiled.Anti-Finger Treatment,Phosphate Tr

Grade:SGCC,Sgcd,Dx51d+Z,S220gd+Z,etc.

Weight:1-8mt,Usually 3-5mt

Quality Standard:En10142/En10346/En10169/JIS3302/Astma755m

Export Markets:Global

Additional Info.

Packing:Standard Export Seaworthy Packing

Standard:0.12-1.8*13-1500

Origin:Zhengzhou China (Mainland)

HS Code:72104900

Production Capacity:100000mt Per Year

Product Description

1. Hot dipped galvanized steel description:

Hot dipped galvanized steel is typically a multiple step process that requires a metal workpiece to be fluxed in molten or aqueous zinc ammonium chloride before a layer of zinc is bonded to it. The pure zinc layer then turns into zinc oxide when it is exposed to oxygen, and finally zinc carbonate after exposure to carbon dioxide.

2. Hot dipped galvanized steel technical process

After cleaning and acid pickling, the steel coil is submerged in melted zinc, a chemical reaction permanently bonds the zinc. The zinc actually permanently becomes a part of it and the successive

Layers are a mixture of zinc and iron. Hot dipped galvanized steel is a special type of steel coil used

In a number of different applications within fabrication and manufacturing environments

3. Hot dipped galvanized steel flow chart

Decoiler--- Shearer ----welder ----pre-treatment ----entry looper--- annealing furnace--- zinc pot

---- air cooling tower ----water cooler--- leveller---- post treatment ---exit looper crimper.

4. Hot dipped galvanized steel main usage scope:

Hot dipped galvanized steel is widely used in home appliances, kitchen utensils, handicrafts, construction formwork, granary, revealed rain, chimneys, roof tile, fire shutter doors, construction

Industry, as raw material for the production of corrugated panels, fencing products, drywall

Panel profiles, ventilation systems etc.

5. Hot dipped galvanized steel advantages:

1) Low iron loss, high magnetic flux strength, comes up to the international advance standard

2) Slight thickness difference between the horizontal and the longitudinal direction, promising the high lamination factor

3) Processing Performance: Easily punched and cut, high dimensional accuracy

4) Insulating coating: Uniform color, good insulation, strong adhesively, high heat resistance, high imputrescibility

5) Smooth surface, no rust, no rolling marks, no cold lap, no crease, no bubble cell, no delaminating defects

| Standard | Steel Grades | Application |

| GB/T 2518-2004 | 01 | Common commercial application |

| 02 | For mechanical engagement | |

| 03 | For stamping | |

| 04 | For deep drawing | |

| 220,250,280,320,350 | For structural components | |

| JIS G 3302-1998 | SGCC | Common application |

| SGCD1 | For stamping | |

| SGCD2 | For deep drawing | |

| DIN EN 10142-2000 | DX51D+Z | For common application and mechanical engagement |

| DX52D+Z | For stamping | |

| DX53D+Z | For deep drawing | |

| DIN EN 10147-2000 | S220GD+Z | For structural components |

FAQ:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

4.What is the validity of your quotation?

Normally 7 days.

5.What is your advantage?

24 hour quick response /Customer oriented/ Credit foremost/ Top quality Excellent

- Q: I am in the market for a good hunting knife under $100. I am primarily looking for a knife that will keep it's edge. What type of steel should I be looking for?

- Get a Kershaw hunting knife. Kershaw uses only good quality knife steel and they have plenty of hunting knives under $100.

- Q: How are steel coils used in the production of oil and gas equipment?

- Steel coils are used in the production of oil and gas equipment as they are shaped and formed into various components such as pipes, tubes, and fittings. These coils provide the necessary strength, durability, and corrosion resistance required for the harsh operating conditions in the oil and gas industry. Additionally, steel coils are often used in the fabrication of storage tanks, pressure vessels, and offshore platforms, ensuring the safe and efficient extraction, processing, and transportation of oil and gas resources.

- Q: If rail ties were melted, would they be like any other type of steel?

- As so much about the railroad is variable, so is the steel used for the rail. For one thing, all rail is not the same size. It is classified by weight per yard. For example, most tangent (straight) track is 139 lbs rail, meaning three feet of it weighs this much. Secondary track, such as found on branch lines and in yards or used on sidings is not as heavy. Track used in curvature may be the same weight, but not always. The reason is there is much more stress imparted to the roadbed in curvature. Most steel on main tracks has a higher carbon content, but there is a point of diminishing returns, as this rail is more brittle as a result. Good luck trying to melt it. In the field, this rail is cut by a saw with diamond studded circular blades. The reason why is it takes a lot more time to try to cut it with an acetylene torch. In the US, certain areas, such as on some bridges, the cross-ties (sleepers) are indeed made of steel, in addition to concrete and wood. The potential for fire is too great for wood in these instances. In addition, if even a single wheel derails, concrete ties tend to explode when stressed this way. All of which makes steel cross-ties worth the extra cost.

- Q: I am in the US and looking for a price on wide flange steel. I need a price of one W10x30 and 20 feet long.

- The price of steel is increasing daily, so an exact answer is rough. A W10x30 is a fairly common shape and shouldn't be too hard to find. For a very rough ballpark number, say $700/ton (installed price), the piece you require should be in the range of about $250.00 or less as I assume you'll be doing the installing. Please don't take this as the gospel, however. Price varies on location, stock, and availability. Open the phone book and contact your local steel supplier. Because the piece you require is fairly short, you might get lucky and find someone who has a waste piece that length that they will give you a good deal on. --------------------------------------... I just checked the AISC web site to verify the number I quoted above and they posted an article stating that the average mill price had just increased to over $1000/ton in May. The best advice I can provide at this point is to buy the W10 now and don't wait any longer.

- Q: Im in the process of replacing the gutters/down spouts on my house. The top of the house is four sided. The bottom level has a porch area with 3 sides, two smaller roofs in the back, and one small roof on the side with all stainless steel gutters. A two story house. Not sure of the demensions. They were made at a Steel Mill where the previous owner, worked.This guy wants to buy the stainless gutters but I need to know the market value of this steel and offer him a price. Can someone tell me what I can sell it for? Does it go by the pound? Foot? Can you give me an idea please? Theres a lot of it! I have no clue what to do! Thanks!

- i know it goes buy the pound but i do not know how mutch a pound.waite for some more answers someone must know.or call your local junk yard and ask them.

- Q: hey therejust wondering about changing nylon strings to steel strings...i have an acoustic guitar and it has nylon strings, but i was thinking about switching to steel strings, as i think it sounds better.this might sound really stupid... but is that possible? i mean they call it a steel stringed GUITAR and nylon stringed GUITAR, so if i wanted to switch would i have to get a whole new guitar? please help, im reaaally confused!thanks

- If it's a Fender, you will need wire cutters to cut the brass barrel shape off the end to feed the string into the clamp. Otherwise on most guitars you just anchor the string barrel at the bridge end, feed the string along the neck and through the hole in the capston and turn the string capston by using the handle The surplus string can just be coiled up. I never had a string winder for years, ---bit of a gimmick --- --but does save time. A point worth noting if considering splashing out on a string winder is that some of them are equipped with a wire cutter as well. 2 Tools in one eh!!

- Q: I bought a stainless steel mood ring two days ago, but would it rust?Thanks in advance!

- This Site Might Help You. RE: Do stainless steel mood rings rust? I bought a stainless steel mood ring two days ago, but would it rust? Thanks in advance!

- Q: I know that it is used for katanas and swords but what is it and is it good i am pretty sure that it is the process of the steel but can I have a little more information.

- It's a special type of steel that was made in Syria. It is used to make swords or knives. It's mostly used in Middle East and South Asia.

- Q: Explain your answers please. I was watching mythbusters and they bought a steel coffin over a wooden one because they thought it would hold more dirt. Now how come bridges that have been made of wood lasted way longer than steel bridges? Or rollercoasts for example.

- steel bridges that have been made of wood lasted way longer than steel bridges NOT true. Why do you think bridges are made from steel or concrete, and not wood? wood rots and splinters and doesn't last more than 10 years when exposed to the weather. .

- Q: I want to get one of these knives but I am having trouble deciding which is the best overall knife??ThanksSOG Trident tigerSOG Vulcan TantoSOG Bi-Polar (Serrated)Cold Steel ScimitarCold Steel Recon 1

- Sog Vulcan Tanto

Send your message to us

Hot Dipped Galvanized Strip/Hot Dipped Galvanized Steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords