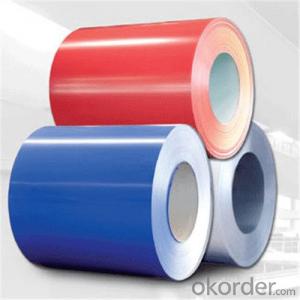

Hot Dipped Galvanized prepainted steel coils

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 300000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

GALVANZIED STEEL COIL(GI)

1,Base Metal:COLD ROLLED(CR)

2,Zinc Coating: z40-z275

3,Thickness:0.15mm-4.0mm(GI)

4,Width:914mm-1250mm

5,Length: according to your requirement (unit of measurement: Ton)

6,Minimum order:25Tons

7,Packaging Details: Fully seaworthy export packing

8,Price Terms:FOB,CIF,CF

9, Terms of payment:T/T 30% in Advance,70%T/T after the copy of B/L or L/C at sight.

10, Coil weight:3-10 ton or client's suggestion

11, Width tolerance:±10mm

12, Spangle:zero spangle , min spangle , regular spangle, big spangle

13.Hot dipped galvanized steel coil & opened sheets

Hot Dipped Galvanized Steel Coil

Range and Production Capacity

| 1# hot dip galvanizing unit | 2# hot dip galvanizing unit | 3# hot dip galvanizing unit | 4# hot dip galvanizing unit | |

Highest process speed m/min | 150 | 150 | GI 160 | 150 | |

GA 60 | |||||

Thickness | 0.25~1.2 | 0.25~1.2 | 0.25~2.0 | 0.15~0.8 | |

Width | 700~1250 | 800~1250 | 800~1350 | 700~1250 | |

Mass of coating g/m² | 60~305 | 60~305 | 60~450 | 60~450 | |

Steel coil inner diameter (mm) | 508/610 | 508/610 | 508/610 | 508/610 | |

Production capacity | 30 | 30 | 30 | 15 | |

Surface structure | Smooth, zero spangle | ||||

Surface treatment | Oiling, passivation or non-chrome passivation, passivation plus oiling, non-chrome passivation plus oiling, fingerprint resistance or non-chrome fingerprint resistance. | ||||

Number and Standard

No.,standard, variety | No. | Executive standard | Application and characteristics |

Stamping steel | DX51D+Z,DX51D+ZF | GB/T 2518 | Ordinary use, mechanical seaming, deep punching, and ultra-deep punching. Coating and welding performances of alloying hot galvanizing are better. |

DX52D+Z,DX52D+ZF | |||

DX53D+Z,DX53D+ZF | |||

DX54D+Z,DX54D+ZF | |||

Structural steel | S220GD+Z,S220GD+ZF | GB/T 2518 | Used for structure. Good corrosion resistance and processability. |

S250GD+Z,S250GD+ZF | |||

S280GD+Z,S280GD+ZF | |||

S320GD+Z,S320GD+ZF | |||

S350GD+Z,S350GD+ZF | |||

S400GD+Z,S400GD+ZF | |||

S500GD+Z,S500GD+ZF |

- Q: What is the purpose of steel coils?

- The purpose of steel coils is to efficiently store and transport large quantities of steel in a compact and secure manner.

- Q: Can you use regular welding rods when welding stainless steel?Thank you.

- You would use stainless steel rod. I have used stainless safety wire that you can buy at the hardware store or Harbor Freight. (Assuming you are TIG welding). I have found that for small jobs it works quite well.

- Q: Are steel pokemon weak against any attacks? If so, what types? (like water, grass, etc.)

- Steel Defensive Strengths: Nearly everything (Only Fire, Ground, and Fighting attacks will put a dent in Steel-types, and Water and Electric do standard damage.) Everything else is wasted effort, especially Poison. (For the whole list, it's Normal, Grass, Ice, Flying, Psychic, Bug, Rock, Ghost, Dragon, Dark, and Steel) Weaknesses: Fire, Fighting, Ground Immune to: Poison Offensive Advantages: Ice, Rock Disadvantages: Water, Fire, Electric, Steel Immunities: None basically fire, fighting and ground

- Q: How are steel coils labeled for identification?

- Steel coils are typically labeled for identification using a combination of unique alphanumeric codes, barcodes, or labels that include important information such as the coil's dimensions, weight, grade, production date, and supplier details.

- Q: How are steel coils annealed to improve their properties?

- Steel coils are annealed by heating them to a specific temperature and then slowly cooling them down. This process helps to relieve internal stresses, improve ductility, and refine the grain structure, resulting in enhanced mechanical properties.

- Q: What are the different types of steel coil finishes for aesthetics?

- There are several different types of steel coil finishes that are used for aesthetics, each offering a unique appearance and texture to the steel surface. Some of the most common types of finishes include: 1. Matte finish: This is a low-gloss finish that provides a smooth, non-reflective surface. It offers a clean and modern look to the steel coil, making it suitable for various applications in architectural and interior designs. 2. Brushed finish: Also known as satin finish, this type of finish is achieved by brushing the steel surface with a fine abrasive material. It creates a subtle, directional grain pattern on the surface, giving it a textured appearance. Brushed finishes are often used in kitchen appliances, decorative elements, and furniture. 3. Mirror finish: As the name suggests, this finish creates a highly reflective surface that resembles a mirror. It is achieved by polishing the steel surface to a high shine using abrasive materials. Mirror finishes are commonly used in architectural applications, such as decorative panels, elevator doors, and signage. 4. Patterned finish: This type of finish involves embossing or etching a pattern onto the steel surface. It can range from simple geometric designs to intricate textures, offering a unique and visually appealing look. Patterned finishes are widely used in interior design, automotive trims, and decorative panels. 5. Textured finish: Textured finishes are created by applying a texture to the steel surface, such as a stucco or diamond pattern. This adds depth and visual interest to the coil, making it suitable for various applications, including wall cladding, roofing, and garage doors. 6. Colored finish: In addition to different surface textures, steel coils can also be finished with various colors. This is achieved through the application of a coating or paint system, which not only enhances the aesthetic appeal but also provides protection against corrosion. Colored finishes are commonly used in architectural applications, such as building facades, window frames, and decorative elements. Overall, the choice of steel coil finish depends on the desired aesthetic outcome, as well as the specific requirements and intended application of the steel product.

- Q: What are the different coil surface finishes?

- There are several different coil surface finishes, including mill finish, brushed finish, embossed finish, and coated finish.

- Q: How are steel coils inspected for chemical composition?

- Steel coils are inspected for chemical composition through a process called spectroscopic analysis. This involves taking a small sample from the coil and subjecting it to various tests, such as X-ray fluorescence or optical emission spectroscopy, to determine the precise elemental composition of the steel. This ensures that the steel meets the required specifications and quality standards.

- Q: Are steel coils used in the oil and gas industry?

- Yes, steel coils are commonly used in the oil and gas industry for various applications such as pipeline construction, storage tanks, and drilling equipment. The strength, durability, and corrosion resistance of steel make it an ideal material for handling the demanding conditions in this industry.

- Q: How are steel coils used in the production of storage tanks and silos?

- Steel coils are used in the production of storage tanks and silos as they provide the necessary structural strength and durability required for these storage structures. The coils are formed, cut, and welded into the desired shape to create the walls and roofs of the tanks and silos. This ensures that the storage vessels can withstand the weight of the stored materials and any external forces exerted on them.

Send your message to us

Hot Dipped Galvanized prepainted steel coils

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 300000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords