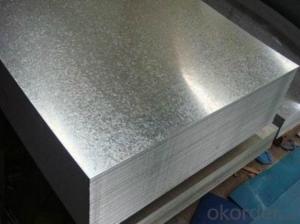

Hot Dipped Galvanized Steel Sheets Regular Spangle

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

product information:

1)Operate Standard: ASTM A653M-04/JIS G3302/DIN EN10143/GBT 2518-2008

2)Grade : SGCD,SGCH, Q195,DX51D

3)Galvanized steel sheet /coil features:

4)Zinc coating :40-180g( as required)

5)width:914-1250mm(914mm, 1215mm,1250mm,1000mm the most common)

6)coil id:508mm/610mm

7)coil weight: 4-10 MT(as required)

8)surface: regular/mini/zero spangle, chromated, skin pass, dry etc.

9)application: Structural use ,roofing, commercial use, household appliance, industry, family;

special application: Wear resistant steel, high- strength - steel plate

Technical data :

Chemical Composition | ||||||

GRADE | C | Si | Mn | P | S | Ti |

SGCC/DX51D+Z | ≤0.10 | ≤0.50 | ≤0.60 | ≤0.10 | ≤0.030 | ≤0.020 |

DX52D+Z | ≤0.10 | ≤0.50 | ≤0.60 | ≤0.10 | ≤0.030 | ≤0.020 |

SGCD/DX53D+Z | ≤0.10 | ≤0.30 | ≤0.50 | ≤0.05 | ≤0.030 | ≤0.020 |

SGCE/DX54D+Z | ≤0.10 | ≤0.30 | ≤0.30 | ≤0.03 | ≤0.020 | ≤0.020 |

DX56D+Z | ≤0.10 | ≤0.30 | ≤0.30 | ≤0.03 | ≤0.020 | ≤0.020 |

Structural | ≤0.20 | ≤0.60 | ≤1.70 | ≤0.10 | ≤0.045 | |

hot dipped galvanized steel coil Mechanical Properties | |||

GRADE | Yield Strength MPa | Tensile Strength MPa | Elongation % |

SGCC(DX51D+Z) | ≥205 | ≥270 | - |

SGCD(DX53D+Z) | - | ≥270 | 38 |

SGCE(DX54D+Z) | - | ≥270 | 40 |

DX56D+Z | - | ≥270 | 42 |

- Q: How is the quality of steel sheets determined?

- The quality of steel sheets is determined by various factors such as the composition of the steel, its mechanical properties, surface finish, and dimensional accuracy. It undergoes rigorous testing for strength, ductility, hardness, and resistance to corrosion. Additionally, the manufacturing process, including the selection of raw materials and adherence to industry standards, plays a significant role in determining the quality of steel sheets.

- Q: What are the different surface treatments available for steel sheets to enhance their appearance?

- There are several surface treatments available for steel sheets to enhance their appearance. Some of the commonly used treatments include galvanizing, which involves applying a layer of zinc to protect against corrosion and provide a shiny finish. Another option is powder coating, where a dry powder is electrostatically applied and then cured to create a durable and attractive coating. Additionally, steel sheets can be polished or brushed to achieve a smooth and reflective surface.

- Q: What are the safety considerations when working with steel sheets?

- When working with steel sheets, some safety considerations include wearing appropriate personal protective equipment (PPE) such as gloves, safety glasses, and steel-toe boots to protect against cuts, burns, and falling objects. It is important to handle steel sheets with caution to avoid injury from sharp edges or corners. Additionally, ensuring proper ventilation in the work area is important to minimize exposure to potentially harmful fumes or dust particles. Regularly inspecting equipment and tools for any defects or damages is crucial to prevent accidents. Finally, following proper lifting techniques and using mechanical aids when necessary can help prevent strains or other musculoskeletal injuries.

- Q: What is the difference between a laminated and non-laminated steel sheet?

- A laminated steel sheet is formed by layering multiple thin sheets of steel together, while a non-laminated steel sheet is made from a single solid piece of steel. The lamination process enhances the strength and durability of the sheet, making it more resistant to bending, warping, and corrosion. On the other hand, non-laminated steel sheets are generally less expensive and may be easier to work with due to their uniform composition.

- Q: What are the different surface treatments available for steel sheets?

- There are several surface treatments available for steel sheets, including galvanizing, painting, powder coating, and plating.

- Q: How do steel sheets perform under heavy loads or pressure?

- Steel sheets are renowned for their extraordinary strength and durability, rendering them highly impervious to immense loads or pressure. With their unique composition and manufacturing process, steel sheets possess an elevated tensile strength that empowers them to endure significant amounts of force without distorting or fracturing. This trait renders steel sheets exceptionally well-suited for applications involving substantial loads or pressure, such as construction, transportation, and industrial machinery. Moreover, steel sheets exhibit an exceptional load-bearing capacity, enabling them to evenly distribute applied pressure across their surface, thereby minimizing the likelihood of structural failure or damage. The rigidity of steel sheets further enhances their ability to withstand heavy loads or pressure, preventing them from bending or buckling and ensuring the integrity of the supported structure or equipment. In summary, steel sheets offer a dependable and robust solution for handling heavy loads or pressure, making them a favored material across various industries.

- Q: What is the typical thickness tolerance of a steel sheet?

- The typical thickness tolerance of a steel sheet can vary depending on the specific grade of steel and the manufacturing process used. However, in general, the typical thickness tolerance for a steel sheet is around ±0.005 to ±0.010 inches.

- Q: What are the different finishes available for steel sheets?

- There are several different finishes available for steel sheets, including hot rolled, cold rolled, galvanized, and stainless steel finishes.

- Q: Are the steel sheets suitable for water tank fabrication?

- Yes, steel sheets are suitable for water tank fabrication. Steel is a strong and durable material that can withstand the weight of water and provide structural support. It is also resistant to corrosion when properly coated or treated, ensuring that the water stored in the tank remains clean and uncontaminated. Additionally, steel sheets can be easily molded and shaped to meet specific design requirements for water tanks. Overall, steel sheets are a reliable and commonly used material for water tank fabrication.

- Q: Can the steel sheets be used for automotive body panels?

- Yes, steel sheets can be used for automotive body panels. Steel is a commonly used material in the automotive industry due to its strength, durability, and ability to withstand impacts. Steel sheets are often used for body panels as they provide structural integrity to the vehicle and can effectively protect the occupants in the event of a collision. Additionally, steel can be easily formed and molded into complex shapes, making it suitable for creating various body panel designs. Overall, steel sheets are a reliable and commonly chosen material for automotive body panels.

Send your message to us

Hot Dipped Galvanized Steel Sheets Regular Spangle

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords