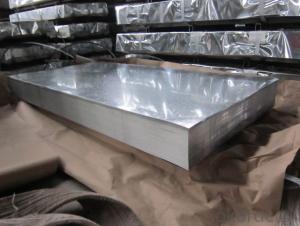

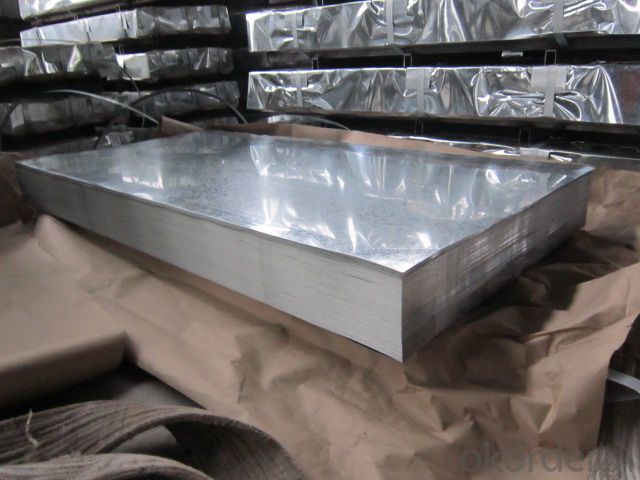

Hot dipped Galvanized Steel Sheet in Sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot-dipped Galvanized Steel Sheet in Sheet

Description:

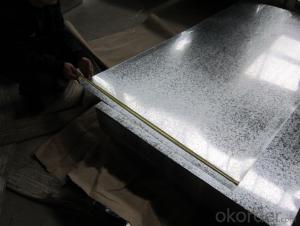

The most external layer is all zinc, but successive layers are a mixture of zinc and iron, with an interior of pure steel. These multiple layers are responsible for the amazing property of the metal to withstand corrosion-inducing circumstances. Zinc also protects the steel by acting as a "sacrificial layer." If rust does take hold on the surface of Galvanized Steel Coil, the zinc will get corroded first. This allows the zinc that is spread over the breach or scratch to prevent rust from reaching the steel.

Architecture Roofs and outside walls of civilian and industrial buildings, garage doors, fencings and window blinds.

Application:

With excellent cold bending molded manufacturablity, good decoration effect, strong anti-corrosion ability, galvanized steel coils and sheets are also pollution-free and easily recycled. Accordingly, they can be used as final products and basic plates of color coated steel coils and widely applied in construction, home appliances, decoration.

Construction, packaging, railway vehicles, agricultural machinery and daily life.

Oiled/dry, Skin-pass/Nonskin-pass, Regular/Minimize/Zero Spangle

Auto Industry Muffler, heat shields of exhaust pipe and catalytic converter, auto parts & accessories under the frame, signboard in highway

Industrial Instruments Electric control cabinet, industrial refrigeration equipment, automatic vending machine

Product Specification:

Base sheet : galvanized steel sheet, pre painted galvanized steel sheet

Zinc:40G-275G

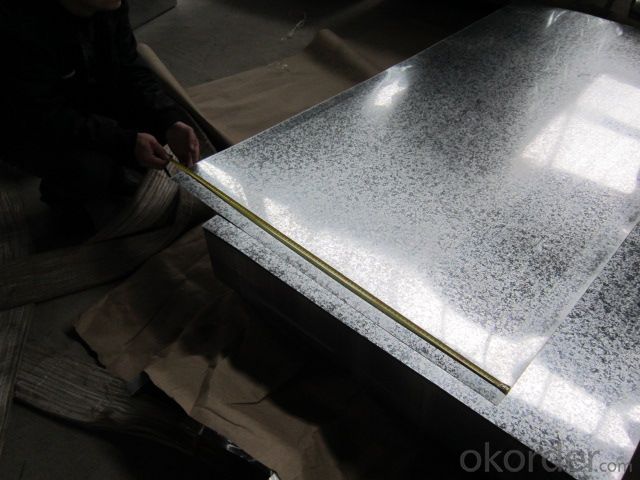

Thickness:0.12mm-3.2mm

Width:600mm-1500mm

Length:1000mm-11800mm or as request

Package:Standard seaworthy export packing: 3 layers of packing, inside is kraft paper,water plastic film is in the middle and outside GI steel sheet to be covered by steel strips with lock.

FAQ:

1.How many pieces for one ton of the Hot-dip Galvanized Steel Sheet?

The pieces for one tone is decided by the thickness of the sheet, but we can make it according to your requirements in the reasonable range.

2. Do you have pallets for the package?

Yes, we must use pallets for the package in order to load.

3. How many tons do you load in one 20’FCL?

Usually we can load 26tons in one 20’FCL container.

- Q: I know this is an alloy, but can it be mixed to form a superior steel? Therefore less likely to stain?

- yes loads

- Q: Basically when i'm older, my dream Job would be, to be to start a steel mill, I've always loved the idea of working in Business and investing in things has always been a hobby of mine. i play games where u invest and make money. all i need is some facts about starting a steel mill?What requirements i need,- How time consuming is it,- How easy is it,- How to get started,- The Perks,- The downsides..how much would it cost to start one, like land, place, iron etc, to get started? also i would need a bank loan, how much money will the bank give me ? 80%??

- Typically, steel mills are worth $20 million to $200 million and are owned by large corporations. Your best bet to own one would be to take over a corporation that already has one. That way you have all the supply lines, customers, experts and other workers already there, too. Stick with investing in going concerns, so you don't need to be an expert in each business to build it up. Get them ready made, learn the details from the people already doing it, then work out ways to improve it. Do not get tempted to borrow even 10c from the scammers who have answered your question. Start saving your real money, reading the financial news, and making small real investments in real stocks.

- Q: My musical saw has, despite my best efforts, got little patches of rust on it. How Do I go about removing the rust without spending too much on rust-removal products and without affecting the properties of the steel?

- I would suggest rust removal by electrolysis. Search youtube for that. It probably will not affect the metal but there are no guarantees. I would run a test on another metal. Also this process can be dangerous because hydrogen gas is a by-product - remember not to smoke or be cooking nearby! The Easy way is with BlackStar Rust Remover. It will turn the metal black and convert the rust to metal which can then be painted or left black.

- Q: and is that different from the components of steel

- Making steel is very energy intensive. Mining the raw ore requires a lot of machinery that uses fuel or electricity . Transporting the ore requires a lot of fuel. Refining not only uses a lot of electricity but coal is added to change the iron ore into steel.

- Q: What materials are used to make steel coils?

- Steel coils consist primarily of steel, an alloy primarily composed of iron and carbon. The choice of steel type for coil production depends on the desired properties and applications. Carbon steel is typically the preferred option due to its strength, durability, and versatility. Additional alloying elements, like manganese, silicon, nickel, or chromium, may be incorporated to enhance specific steel characteristics or properties. To produce steel coils, the raw materials are melted, the molten steel is refined, and specialized equipment and processes are employed to shape it into coils.

- Q: How are steel coils stored to prevent damage?

- Steel coils are typically stored in a way that prevents damage and ensures their integrity. One common method is to stack the coils in a horizontal position. This helps distribute the weight evenly across the coils, minimizing the risk of deformation or damage. In addition, wooden or steel dunnage is often placed between each layer of coils to provide support and prevent them from shifting during storage or transportation. To further protect the coils from damage, they are often stored indoors or in covered areas to shield them from exposure to the elements. This helps prevent rusting or corrosion, which can compromise the quality of the steel. If outdoor storage is necessary, the coils may be covered with weather-resistant tarps or protective coatings to minimize the impact of rain, snow, or sunlight. Furthermore, it is important to consider the stacking height to prevent excessive pressure on the lower coils. To avoid damage, coils are typically stacked in a way that ensures the weight from the upper layers is distributed evenly across the lower ones. This can include using specialized stacking equipment or racks designed to handle the weight and dimensions of the coils. Overall, proper storage of steel coils involves careful consideration of weight distribution, protection from the elements, and minimizing contact between coils to prevent damage and maintain their quality.

- Q: So I want to get my 3+ wood shafted with a dynamic gold shaft because i need a stiffer shaft but dont want to spend much on it.I've never swung a steel shafted wood, but I hear that it is more consistent that graphite....Plus, since the cost of steel is only $15 compared to the $65 graphite, not to mention installation charges.So yeah...... How good is steel for fairway woods?BTW, my swing speed is about 95 but i can amp it up to 110 (with control, that is)

- If your club has a graphite shaft in it and you want to switch to steel an option is to get a dynamic gold lite shaft. The other option is to make sure you trim the shaft to the 42 length with the gold shaft to lighten up the swing weight. You can get away with about 42 3/4 with the lite shaft. I have found steel to be very consistent in my fairway woods and don't think I'll ever go back to graphite. I have mine cut to 42 1/2 for the 3 wood and 41 1/2 for the 5 wood with Dynamic gold s300 and they're fine.

- Q: How do steel coils contribute to energy efficiency in buildings?

- Steel coils contribute to energy efficiency in buildings through their use in HVAC systems. Steel coils are commonly used in air conditioning and heating units as a part of the heat exchanger. The coils help to transfer heat between the indoor and outdoor environments, allowing for efficient temperature control. By efficiently transferring heat, steel coils help to reduce energy consumption and ensure that the building's HVAC system operates at optimal levels. This ultimately contributes to energy savings and increased energy efficiency in buildings.

- Q: Where are the coils and the steel plates used? Where did the steel plate come from?

- The use of steel coils, refrigerators, washing machines, household appliances, and other industries, parcels are winding.Steel plates can also be found everywhere: airplanes, guns, trains, ships, space shuttles, spaceships, automobiles, etc..Steel plate through mining - sintering - iron smelting - smelting - forming.

- Q: My teacher says if they were that they would still be standing today. I'm not sure if he means the reinforced steel in the concrete beams, columns etc or if the whole beams and columns floor etc were were made of reinforced steel.

- Reinforced Steel is found in concrete, and if the towers were built with reinforced concrete (concrete beams with rebar) then they would likely still be standing. The twin towers were made of steel. When steel is heated up, it deforms and collapses, which is why it didnt stand up. One of the top 2 things against steel is that it is not fire resistant.

Send your message to us

Hot dipped Galvanized Steel Sheet in Sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords