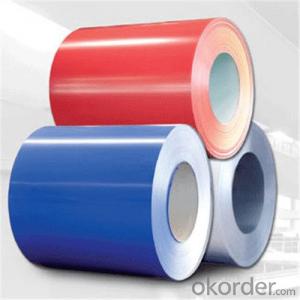

Hot dipped galvanized prepainted steel coils

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 300000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

GALVANZIED STEEL COIL(GI)

1,Base Metal:COLD ROLLED(CR)

2,Zinc Coating: z40-z275

3,Thickness:0.15mm-4.0mm(GI)

4,Width:914mm-1250mm

5,Length: according to your requirement (unit of measurement: Ton)

6,Minimum order:25Tons

7,Packaging Details: Fully seaworthy export packing

8,Price Terms:FOB,CIF,CF

9, Terms of payment:T/T 30% in Advance,70%T/T after the copy of B/L or L/C at sight.

10, Coil weight:3-10 ton or client's suggestion

11, Width tolerance:±10mm

12, Spangle:zero spangle , min spangle , regular spangle, big spangle

13.Hot dipped galvanized steel coil & opened sheets

Hot Dipped Galvanized Steel Coil

Range and Production Capacity

| 1# hot dip galvanizing unit | 2# hot dip galvanizing unit | 3# hot dip galvanizing unit | 4# hot dip galvanizing unit | |

Highest process speed m/min | 150 | 150 | GI 160 | 150 | |

GA 60 | |||||

Thickness | 0.25~1.2 | 0.25~1.2 | 0.25~2.0 | 0.15~0.8 | |

Width | 700~1250 | 800~1250 | 800~1350 | 700~1250 | |

Mass of coating g/m² | 60~305 | 60~305 | 60~450 | 60~450 | |

Steel coil inner diameter (mm) | 508/610 | 508/610 | 508/610 | 508/610 | |

Production capacity | 30 | 30 | 30 | 15 | |

Surface structure | Smooth, zero spangle | ||||

Surface treatment | Oiling, passivation or non-chrome passivation, passivation plus oiling, non-chrome passivation plus oiling, fingerprint resistance or non-chrome fingerprint resistance. | ||||

Number and Standard

No.,standard, variety | No. | Executive standard | Application and characteristics |

Stamping steel | DX51D+Z,DX51D+ZF | GB/T 2518 | Ordinary use, mechanical seaming, deep punching, and ultra-deep punching. Coating and welding performances of alloying hot galvanizing are better. |

DX52D+Z,DX52D+ZF | |||

DX53D+Z,DX53D+ZF | |||

DX54D+Z,DX54D+ZF | |||

Structural steel | S220GD+Z,S220GD+ZF | GB/T 2518 | Used for structure. Good corrosion resistance and processability. |

S250GD+Z,S250GD+ZF | |||

S280GD+Z,S280GD+ZF | |||

S320GD+Z,S320GD+ZF | |||

S350GD+Z,S350GD+ZF | |||

S400GD+Z,S400GD+ZF | |||

S500GD+Z,S500GD+ZF |

- Q: im buying a new guitar,, it has a built in tuner and its semi acoustic (can be plugged into an amplifier) ,, im trying to choose which strings are better ,, steel or nylon..?

- Musical style speaks volumes when it comes to this issue. Those who want high volume will be unhappy with unamplified nylon string guitars. From my perspective, the basic difference between steel and nylon is this: steel strings ring and nylon strings resonate. The volume produced by steel is generally much greater than nylon but, to my way of thinking, the sound resonance produced by the wood of your guitar is largely masked by steel strings. If you have a decently made guitar (generally, around a thousand dollars and up), the sound interplay between the wood and the strings in a nylon guitar is magical across the entire frequency range. With a steel string guitar, the sound produced by the vibrating string overpowers the wood resonance at all but low frequencies. Personally, I'll take a nylon string guitar any day for the sensitivity gained from the interplay between wood and vibrating string.

- Q: i have a sword and some knives that have this grade steel. so is it a high grade or low grade? and how can i tell the differance between a high grade and a low grade?

- You can probably Google the strength properties for 440. The question your question asks is, Why?

- Q: What are the different types of steel surface treatments for coils?

- There are several types of steel surface treatments for coils, including pickling, oiling, galvanizing, and painting. Pickling involves removing surface impurities and scale through the use of acid solutions. Oiling is a process where a thin layer of oil is applied to the coil surface to prevent rust and improve handling. Galvanizing involves coating the steel with a layer of zinc to provide corrosion resistance. Painting is another surface treatment where a protective layer of paint is applied onto the coil surface to enhance durability and aesthetics.

- Q: What are the different grades of steel used for making coils?

- When making coils, various grades of steel are commonly utilized, depending on specific requirements and applications. Some frequently employed grades are: 1. Mild steel, also referred to as low carbon steel, is often employed for coil production due to its favorable characteristics of formability, weldability, and machinability. It is suitable for diverse applications where strength and durability are not the primary concerns. 2. High carbon steel, which contains elevated carbon levels, offers increased strength and hardness. This grade is commonly used for coils that require high strength and resistance to wear, such as springs and automotive components. 3. Stainless steel, characterized by a high chromium content, exhibits excellent corrosion resistance. Coils made from stainless steel are commonly utilized in applications where resistance to rust and staining is critical, such as kitchen appliances, automotive trim, and medical equipment. 4. Galvanized steel, coated with a layer of zinc, provides exceptional corrosion resistance. Galvanized steel coils find common use in outdoor applications that involve exposure to moisture and other elements, including roofing, fencing, and HVAC ductwork. 5. Electrical steel, specifically designed for electrical applications like transformers, motors, and generators, possesses low impurity levels and is optimized for high magnetic permeability and low core loss. 6. Advanced high-strength steel (AHSS), engineered to offer exceptional strength while maintaining good formability, is frequently employed in the automotive industry. AHSS coils contribute to lightweighting vehicles while ensuring structural integrity and crashworthiness. These examples represent only a fraction of the steel grades employed in coil manufacturing. The choice of a specific grade depends on factors such as the intended application, desired properties, and cost considerations.

- Q: Well im currently doing a project. Wanna help me? Because trust me, i really need it. You know how steel was created in China? If you didnt, you just learned something newww(: but anyways got any info on that? Websites? or just info from websites? Well lemme know because if its the best you get Best Answer Easy points right? (: Okay thanksss (:

- Steel is created in a primitive way whenever iron oxide ore (red dirt) is mixed with wood and burned. Seemingly everyone has a pet theory how their own selected country was the first to notice and do it on purpose. Regards, Larry.

- Q: Can steel coils be coated with polymer?

- Yes, steel coils can be coated with polymer.

- Q: How are steel coils used in automotive manufacturing?

- Steel coils are used in automotive manufacturing to produce various components and parts such as body panels, chassis, doors, and other structural parts. The coils are processed through different techniques like cutting, stamping, and welding to shape them into the desired form. This allows for the production of strong and durable automotive parts, ensuring the safety and reliability of vehicles.

- Q: Help please.What atoms are there in steel?Like water is equals to 1 Oxygen atom + 2 Hydrogen atoms.Thnx 4 d help.

- Steel is mostly iron with a small amount (less than 1%) of carbon added. Stainless steel has other metals like chromium and nickel added.

- Q: Can steel coils be stored in unheated warehouses?

- Yes, steel coils can be stored in unheated warehouses as long as proper precautions are taken to prevent moisture and corrosion.

- Q: How are steel coils used in the production of solar panels?

- Steel coils are used in the production of solar panels as a crucial component for the frame and support structure. The coils are shaped and cut to size, providing the necessary strength and stability to hold the solar cells and other components securely in place.

Send your message to us

Hot dipped galvanized prepainted steel coils

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 300000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords