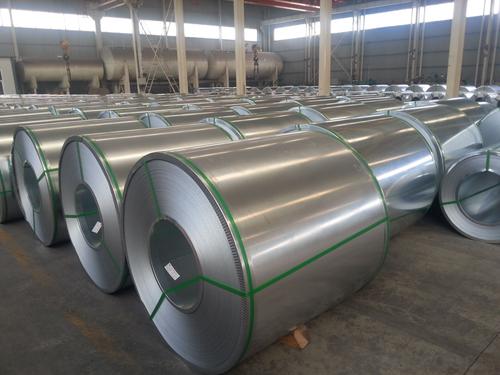

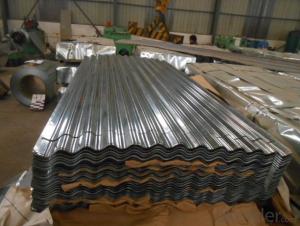

Hot dipped galvanized steel coils/Sheets

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Commodity | Hot dip galvanized steel coil and sheet |

Technical Standard: | JIS 3302 / ASTM A653 / EN10143 |

Grade | DX51D / DX52D/ DX53D/ S250,280,320GD |

Types: | Commercial / Drawing / Deep Drawing / Structural quality |

Width | 500/650/726/820/914/1000/1200/1219/1220/1250mm |

Thickness | 0.12-2.8mm |

Type of coating: | Galvanized |

Zinc coating | Z30-275g/m2 |

Surface Treatment | Chromed / Skin-pass/ Oiled/Slightly Oiled/ Dry/ Anti-fingerprint |

Surface structure: | Zero spangle / minimized spangle / regular spangle/ big spangle |

ID coil | 508mm or 610mm |

Coil weight | 3-8 MT per coil |

Package: | Properly packed for ocean freight exportation in 20''containers |

Application: | Industrial panels, roofing and siding for painting |

Price terms | FOB,CFR,CIF |

Payment terms | T/T or L/C |

Delivery time | Within 30 days |

Remarks | Insurance is all risks |

MTC will be handed on with shipping documents | |

We accept the third party certification test,such as SGS/BV |

Technical data :

Hot dipped galvanized coil Technical Data

Chemical Composition | ||||||

GRADE | C | Si | Mn | P | S | Ti |

SGCC/DX51D+Z | ≤0.10 | ≤0.50 | ≤0.60 | ≤0.10 | ≤0.030 | ≤0.020 |

DX52D+Z | ≤0.10 | ≤0.50 | ≤0.60 | ≤0.10 | ≤0.030 | ≤0.020 |

SGCD/DX53D+Z | ≤0.10 | ≤0.30 | ≤0.50 | ≤0.05 | ≤0.030 | ≤0.020 |

SGCE/DX54D+Z | ≤0.10 | ≤0.30 | ≤0.30 | ≤0.03 | ≤0.020 | ≤0.020 |

DX56D+Z | ≤0.10 | ≤0.30 | ≤0.30 | ≤0.03 | ≤0.020 | ≤0.020 |

Structural | ≤0.20 | ≤0.60 | ≤1.70 | ≤0.10 | ≤0.045 | |

|

|

|

|

|

| |

Hot dipped galvanized steel coil Mechanical Properties | |||

GRADE | Yield Strength MPa | Tensile Strength MPa | Elongation % |

SGCC(DX51D+Z) | ≥205 | ≥270 | - |

SGCD(DX53D+Z) | - | ≥270 | 38 |

SGCE(DX54D+Z) | - | ≥270 | 40 |

DX56D+Z | - | ≥270 | 42 |

- Q: How are steel coils used in the production of steel rings?

- Steel coils are used in the production of steel rings by being fed through a machine that cuts and shapes the coil into individual rings. These rings can then be further processed and manipulated to create a wide range of steel products, such as bearings, pipe fittings, or automotive components.

- Q: What is the role of steel coils in HVAC systems?

- Steel coils play a crucial role in HVAC (heating, ventilation, and air conditioning) systems as they are responsible for facilitating the transfer of heat between the air and the refrigerant. In HVAC systems, steel coils are typically used in two main components: the condenser coil and the evaporator coil. The condenser coil is located in the outdoor unit of an HVAC system and its primary function is to release the heat from the refrigerant into the surrounding air. This coil is made up of multiple steel tubes that are bent into a serpentine shape and are attached to aluminum fins. As the hot refrigerant flows through these tubes, the steel coils ensure maximum surface area contact with the surrounding air, allowing for efficient heat transfer. Through this process, the heat is dissipated into the outdoor environment, resulting in the cooling of the refrigerant. On the other hand, the evaporator coil is situated in the indoor unit of the HVAC system and its role is to absorb heat from the air inside the building. Similar to the condenser coil, the evaporator coil consists of steel tubes that are connected to aluminum fins. The refrigerant, in a cold state, flows through these tubes, and as warm air from the building passes over the coils, the heat is transferred from the air to the refrigerant. This heat absorption process cools down the air, which is then circulated back into the building, providing the desired cooling effect. Overall, steel coils in HVAC systems are essential for heat transfer between the air and the refrigerant. Their design and placement allow for efficient cooling or heating of the air, depending on the system's mode of operation. Without steel coils, HVAC systems would not be able to effectively regulate the temperature and provide the desired comfort levels in residential, commercial, and industrial buildings.

- Q: How can defects in steel coils be detected?

- Defects in steel coils can be detected through various non-destructive testing methods such as visual inspection, ultrasonic testing, magnetic particle inspection, eddy current testing, and radiographic testing. These techniques help identify surface cracks, internal flaws, irregularities in thickness, and other defects, ensuring the quality and integrity of the steel coils.

- Q: How do steel coils contribute to corrosion resistance in products?

- Corrosion resistance in products is achieved through a combination of factors provided by steel coils. Firstly, the coils are typically constructed from stainless steel, which contains a high concentration of chromium. This chromium forms a passive film on the steel's surface, acting as a protective oxide layer that prevents corrosion. Furthermore, this film possesses the ability to self-heal, regenerating itself if damaged or scratched, thereby ensuring continuous corrosion protection. In addition, the steel coils undergo a process known as galvanization, which involves applying a layer of zinc to the steel's surface. This zinc layer functions as a sacrificial anode, corroding preferentially to the steel. This sacrificial corrosion shields the underlying steel, effectively preventing the formation of rust and other types of corrosion. Moreover, steel coils can be coated with various protective materials like epoxy or polyurethane to enhance their corrosion resistance. These coatings act as an additional physical barrier, preventing moisture, chemicals, and other corrosive elements from reaching the steel surface. Lastly, steel coils can be manufactured with specific alloying elements such as nickel or molybdenum, further enhancing their resistance to corrosion. These alloying elements bolster the strength and durability of the steel, enabling it to withstand harsh and corrosive environments more effectively. In summary, steel coils contribute to the corrosion resistance of products by utilizing stainless steel, galvanization, protective coatings, and alloying elements. The implementation of these measures ensures that products retain their structural integrity and appearance over time, even under demanding and corrosive conditions.

- Q: How are steel coils used in the production of metal signs?

- Steel coils are used in the production of metal signs as they are processed and shaped into flat sheets that serve as the base material for the signs. These coils are unrolled and flattened, then cut and formed into the desired shape before being painted or coated for aesthetics and protection.

- Q: Can steel coils be coated with noise-reducing materials?

- Yes, steel coils can be coated with noise-reducing materials.

- Q: I have a knife with AUS8 Stainless Steel. No idea what that means. I want to know some of the best stainless steels for knifes and all you can tell me about stainless steel would be great. I was browsing google and looking at grades and had no idea what all the numbers meant. Thanks!

- Actually-good grades of stainless is superior to high carbon steels which has been proven by countless tests. Aus8 is a japanese steel from what I know, so I'm not sure what the letter and number designation means. From what I know, Aus8 has similar properties to 440B though with a carbon content of around ~.74%. This is lower content then most other blade steels meaning it has lower edge retention. The stainless steels I'd consider to be best are: Ats-34: Less corrosion resistant then 440c, but is tougher then 440c and still holds a edge quite well 440c: Probably the best all around steel on the market for its price. Highest corrosion resistance and very good edge retention. I wouldn't recommend it on choppers though, a tougher steel like the one mentioned above would probably be better for that. A/B/C indicates the carbon content going from least to greatest. 4xx indicates that its a chrome martensitic steel. 40 indicates that its a high carbon grade compared to (4)20 which has less then .5 percent. CpmS30v: Slightly lower corrosion resistance then 440c due to it not taking a mirror finish, but very high edge retention and improved toughness. Cpm indicates that it's made by compressed particle metallurgy while the v indicates that its a vanadium alloy. I'm not sure what the S30 indicates.

- Q: Can steel coils be stored outdoors?

- Yes, steel coils can be stored outdoors. However, it is important to protect them from exposure to moisture and extreme weather conditions, as these can cause corrosion and damage to the coils. Proper covering or shelter should be provided to ensure their longevity and quality.

- Q: Can steel coils be coated with thermally conductive materials?

- Yes, steel coils can be coated with thermally conductive materials. These coatings, such as thermally conductive paints or ceramic coatings, are designed to enhance heat transfer properties and improve the thermal conductivity of the steel coils. This can be beneficial in various applications where efficient heat dissipation or thermal management is required.

- Q: How are steel coils used in the agricultural sector?

- Various purposes in the agricultural sector call for the widespread use of steel coils. One primary utilization is seen in the construction of farm machinery and equipment. Tractors, plows, harvesters, and other heavy-duty machinery are frequently manufactured using steel coils. The exceptional strength and durability of steel make it an ideal material for such applications, as it can endure the challenging conditions of agricultural work. Furthermore, agricultural buildings and structures heavily rely on steel coils in their construction. Steel is renowned for its superior structural integrity, making it a popular choice for barns, storage units, and other agricultural facilities. Steel coils are frequently employed to establish the framework and support systems of these structures, providing stability and long-lasting durability. Moreover, irrigation systems also rely on steel coils in their production. Steel coils are often used to create the pipes and tubes used for water transportation in agricultural irrigation systems. Steel's resistance to corrosion and its ability to handle high-pressure flows make it an excellent choice for this particular application. To summarize, steel coils hold a critical role in the agricultural sector. Whether it be the construction of farm machinery and buildings or the development of irrigation systems, steel's strength and durability make it the preferred material in this industry.

Send your message to us

Hot dipped galvanized steel coils/Sheets

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords