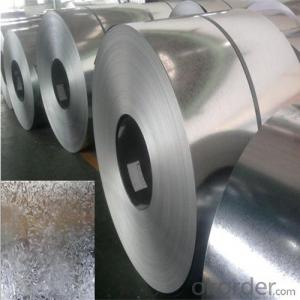

HOT-DIP GALVANIZED STEEL

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 12000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

THICKNESS:0.18mm-1.5mm

WIDTH:900mm-1250mm

COATING MASS:Z30-Z275

SPANGLE:Minimized Spangle,Zero Spangle

SURFACE TREATMENT:N0on or Chromated,Non or Oiled,Non or Anti Finger Print

COIL INNER DIAMETER:508mm/610mm

COIL WEIGHT:3mt-7m

- Q: How are steel coils used in the production of electrical motors?

- Steel coils are used in the production of electrical motors as they serve as the core component of the motor's electromagnetic system. These coils are wrapped around an iron core, creating an electromagnetic field when electricity flows through them. This electromagnetic field generates the necessary force that allows the motor to convert electrical energy into mechanical energy, enabling the motor to function and perform various tasks.

- Q: I want to buy a chain that will last a long time and that i can wear ALL the time.What are the disadvantages to stainless steel jewelry?Does it look as good as silver?Is there much diference in apperance?

- I okorder /... Go for the stainless steel chain if you like it. It does look different than silver and has a more machine like metallic luster (I think). By the way, good stainless steel chains are often more expensive than silver. So don't let anyone laugh at you.

- Q: I bought a damascus steel knife. It will be used for display. Nothing like hunting/skinning. If It is just sitting around, will it rust? (assuming that it isn't getting wet) Thanks for the help.

- From that point of view the strength or edge-holding ability means very little. Specifically, the bushcraft knife is pattern welded steel. True damascus or Wootz steel is something you'll only find in museums and private collections. they stopped making it several hundred years ago. Despite what many people have claimed, Wootz damascus was inferior to modern tool steels in every respect. It was a brittle, dirty material.

- Q: What are the different surface treatments applied to steel coils?

- Some of the different surface treatments applied to steel coils include galvanizing, which involves coating the steel with a layer of zinc to protect it from corrosion, painting or powder coating to enhance the aesthetics and provide additional protection, and passivation to remove any impurities on the surface and improve its corrosion resistance.

- Q: How are steel coils used in the production of agricultural storage tanks?

- Steel coils are used in the production of agricultural storage tanks to create the structural framework and walls of the tanks. The coils are rolled and formed into the desired shape, providing strength and durability to store various agricultural materials such as grains, fertilizers, and liquids.

- Q: What are the common coil lengths available for steel coils?

- The common coil lengths available for steel coils vary depending on the industry and specific requirements. However, some standard coil lengths are commonly used across various applications. These include coil lengths of 100 feet (30.48 meters), 200 feet (60.96 meters), 300 feet (91.44 meters), and 500 feet (152.4 meters). These lengths are often used in industries such as construction, manufacturing, and automotive, where steel coils are widely used for various purposes. It is important to note that coil lengths can also be customized based on specific project needs or customer preferences.

- Q: How are steel coils transported?

- Steel coils are typically transported using specialized flatbed trucks or railcars. The coils are carefully loaded onto these vehicles and secured using straps or chains to prevent any movement during transit. In some cases, shipping containers are also used to transport steel coils via cargo ships.

- Q: How are steel coils used in the manufacturing of airbags?

- Steel coils are used in the manufacturing of airbags to provide structural support and stability. These coils are typically incorporated into the airbag module, helping to maintain its shape and ensure proper deployment in the event of a collision.

- Q: How are steel coils protected from mechanical damage?

- Steel coils are typically protected from mechanical damage through the use of various packaging materials such as wooden crates, steel frames, or protective plastic wraps. These measures ensure that the coils remain intact and safeguarded during transportation, handling, and storage, minimizing the risk of any potential mechanical damage.

- Q: No. Not Stainless steel, I mean STEEL.Not a specific type, but STEEL.Thanks. xo

- This Site Might Help You. RE: Is Steel a Pure Substance or a Mixture? No. Not Stainless steel, I mean STEEL. Not a specific type, but STEEL. Thanks. xo

Send your message to us

HOT-DIP GALVANIZED STEEL

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 12000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords