Hot Dip Galvanized Steel Sheet/Z140 Galvanized Steel Coil

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

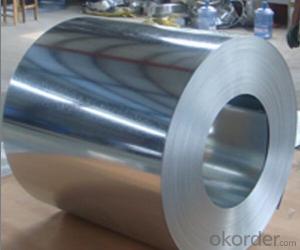

Hot Dip Galvanized Steel Sheet/Z140 Galvanized Steel Coil

Details of Hot Dip Galvanized Steel Sheet/Z140 Galvanized Steel Coil

| Grade | Q195 SGCC SGCH CGCC CGCH |

| Standard | JIS GB ASTM DIN |

| Base plate | Cold rolled steel coil ,hot dipped steel coil |

| Zinc coating | Hot dipped galvanized (GI) |

| Zinc thickness | 60-275G/m2 |

| Thickness | 0.15-1.5 mm |

| Width | 914mm, 1000mm,1100mm,1219mm, 1250mm etc |

| Wave depth | 18(+/-2mm) |

| Product feature | water resistance, light weight, easy installation, aesthetic, high tensile |

| Packing | standard export seaworthy packing |

| Delivery time | in 30 days |

| Application | exterior and interior wall, roofs, and soffits |

| Qualification | TUV, ISO9001:2008,ISO14001:2004 |

Specification of Hot Dip Galvanized Steel Sheet/Z140 Galvanized Steel Coil

| NAME | PPGI | GALVANIZED | GALVALUME/ZINCALUME |

| CERTIFICATE | ISO9001:2008 | ||

| STANDARD | EN10142 JIS G3302 GB/T-12754-2006 | ASTM A653M JIS G3302 GB/T2518 EN 10142 | ASTM A792M JIS G3321 JIS G3317 EN 10215 |

| GRADE | CGCC CGCH CGCD1-CGCD3 CGC340-CGC570 | DX51D+Z/DX52D+Z/S250GD+Z S300GD+Z/S350GD+Z/S550GD+Z SGCC/SGCH/SGCD1-SGCD3/SGC340-SGC570 G2+Z/G3+Z/G250+Z/G300+Z G350+Z/G550+Z | DX51D+AZ/DX52D+AZ/S250GD+AZ S300GD+AZ/S350GD+AZ/S550GD+AZ SGLCC/SGLCD/SGLC300-SGLC570 G2+AZ/G3+AZ/G250+AZ/G300+AZ G350+AZ/G550+AZ |

| COATING | RAL COLOURS | Z60g/m2 to Z275g/m2 | AZ30g/m2 to AZ150g/m2 |

| SIZE | (0.13mm-1.5mm)X1000mm OR as requirements | (0.13mm-4.0mm)X1500mm OR as requirements | (0.12mm-4.0mm)X1500mm OR as requirements |

| TYPE | Steel coil Steel sheets/plates Corrugated steel sheets/plates | Steel coil Steel sheets/plates Corrugated steel sheets/plates | Steel coil Steel sheets/plates Corrugated steel sheets/plates |

| TECHNIQUE | Hot rolled-cold rolled -galvalume /galvanized -PPGI/PPGL | Hot rolled-cold rolled -galvanized | Hot rolled-cold rolled -galvalume /Aluzinc |

| SURFACE TREATMENT | Mini/regular/big/zero spangle,Chromate treatment /chromate-free treatment /untreated unoile/oiled, TENSION LEVELLER SKIN PASS anti-fingerprint/un-anti-fingerprint, Coating,color | Mini/regular/big/zero spangle,Chromate treatment /chromate-free treatment /untreated unoile/oiled,TENSION LEVELLERT SKIN PASS anti-fingerprint/un-anti-fingerprint,Coating | |

| APPLICATION | Structural use ,roofing, commercial use, household appliance, industry, family Roofs and outside walls of civilian and industrial buildings, garage doors, fencings and window blinds; Outer clad sheets for washing machine, refrigerator, televi-sion, air conditioner and ventilation system, explosion-proof strip, solar water heater and appliance parts; Muffler, heat shields of exhaust pipe and catalytic converter, auto parts & accessories under the frame, signboard in high -way; Electric control cabinet, industrial refrigeration equipment, automatic vending machine; Wear resistant steel, high- strength - steel plate | ||

Supplier of the Hot Dip Galvanized Steel Sheet/Z140 Galvanized Steel Coil

CNBM International Corporation is the most import and export platform of CNBM group(China National Building Material Group Corporation) ,which is a state-owned enterprise, ranked in 270th of Fortune Global 500 in 2015.

With its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high quality series of refractories as well as technical consultancies and logistics solution.

Products Show

FAQ:

Are you a trading company or manufacturer? | Manufacturer |

What’s the MOQ? | 3 metric ton |

What’s your delivery time? | 15-35 days after downpayment received |

Do you Accept OEM service? | Yes |

what’s your delivery terms? | FOB/CFR/CIF |

What's the Payment Terms? | 30% as deposit,70% before shipment by T/T |

Western Union acceptable for small amount. | |

L/C acceptable for large amount. | |

Scrow ,Paybal,Alipay are also ok | |

Why choose us? | Chose happens because of quality, then price, We can give you both. Additionally, we can also offer professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposals. |

What's your available port of Shipment? | Main Port, China |

What’s your featured services? | Our service formula: good quality+ good price+ good service=customer's trust

|

Where are your Market? | Covering more than 160 countries in the world |

- Q: What are the requirements for special steel used in railway applications?

- Due to the demanding nature of the industry, the railway sector has stringent requirements for the special steel it uses. Here are a few key considerations: 1. Strength and durability are of utmost importance. The steel must possess exceptional strength and durability to withstand the heavy loads and constant vibrations experienced by trains. This is crucial in preventing deformation, fatigue, and failure of steel components. 2. Wear resistance is another vital requirement. The constant movement of trains subjects railway tracks and other components to significant wear and tear. Therefore, the special steel used in railway applications should have good wear resistance. This ensures a longer service life and reduces maintenance costs. 3. Corrosion resistance is imperative due to exposure to various environmental conditions, such as rain, snow, and chemicals. The special steel must possess high corrosion resistance to prevent rusting and degradation. This ensures the longevity of the components. 4. Fatigue resistance is crucial since trains undergo repetitive loading cycles that can lead to fatigue in steel components. Special steel with excellent fatigue resistance is necessary to prevent cracking and failure. This ensures the safety and reliability of railway systems. 5. High impact toughness is essential. Special steel used in railway applications must absorb energy during sudden shocks or accidents. This prevents catastrophic failures and ensures the safety of passengers and railway personnel. 6. Heat resistance is a requirement for certain railway applications, especially high-speed trains. The steel components are exposed to high temperatures due to friction or other sources. Special steel should possess good heat resistance to maintain its mechanical properties and structural integrity even under elevated temperatures. 7. Dimensional stability is crucial to maintain the required tolerances and alignment of various components in railway applications. Special steel should exhibit excellent dimensional stability. This ensures smooth operation, reduces noise, and prevents excessive wear. These are the primary requirements for special steel used in railway applications. Meeting these requirements is crucial for the safe, reliable, and efficient operation of railway systems.

- Q: How is high-strength stainless steel used in the production of structural components?

- High-strength stainless steel is commonly utilized in the production of structural components due to its remarkable properties. Its high tensile strength, corrosion resistance, and durability make it ideal for constructing critical load-bearing structures such as bridges, buildings, and infrastructure. Additionally, the stainless steel's ability to withstand extreme environmental conditions and its aesthetic appeal further enhance its usage in various structural applications.

- Q: What are the main applications of special steel in the semiconductor industry?

- Special steel is widely used in the semiconductor industry for various applications. One of the main applications is in the production of wafer fabrication equipment, such as vacuum chambers, deposition tools, and etching systems. The high strength, corrosion resistance, and thermal stability of special steel make it suitable for these critical components that operate under extreme conditions. Additionally, it is also used in the manufacturing of precision molds and dies required for semiconductor packaging processes. Overall, special steel plays a vital role in ensuring the reliability, performance, and quality of semiconductor manufacturing processes.

- Q: What are the main characteristics of alloy steel?

- The main characteristics of alloy steel include high strength, hardness, and durability due to the presence of different alloying elements such as manganese, nickel, chromium, and molybdenum. It also exhibits good resistance to corrosion, wear, and heat, making it suitable for various applications in industries such as automotive, aerospace, and construction. Additionally, alloy steel offers excellent machinability and weldability, allowing for ease of fabrication and customization.

- Q: How is case-hardening steel used in the manufacturing of gears?

- Case-hardening steel is used in the manufacturing of gears to enhance their durability and strength. The process involves heating the steel to a high temperature and then rapidly cooling it to create a hard outer layer, known as the case, while maintaining a relatively softer core. This hardened surface provides resistance to wear, abrasion, and fatigue, allowing the gears to withstand heavy loads and prolonged use. Additionally, case-hardening steel also improves the gear's ability to withstand impact and retain its shape, ensuring efficient and reliable performance in various mechanical applications.

- Q: What are the different non-destructive evaluation techniques used for special steel?

- Some of the different non-destructive evaluation techniques used for special steel include ultrasonic testing, magnetic particle inspection, liquid penetrant testing, radiographic testing, and eddy current testing. These techniques allow for the detection of defects or flaws in the steel without causing any damage to the material.

- Q: What are the different methods of coating special steel?

- There are several different methods of coating special steel to enhance its performance and protect it from corrosion or other forms of damage. Some of the commonly used methods include: 1. Galvanizing: This method involves coating the steel with a layer of zinc, either through hot-dip galvanizing or electroplating. The zinc layer provides excellent corrosion resistance and acts as a sacrificial anode, protecting the steel from rusting. 2. Powder coating: In this process, a dry powder is applied electrostatically to the steel surface and then cured under heat. The powder melts and fuses into a protective layer that provides an attractive finish, as well as resistance to chipping, scratching, and corrosion. 3. Electroplating: This method involves immersing the steel in a solution containing a metal ion, such as chromium or nickel, and passing an electric current through it. The metal ions are then deposited onto the steel surface, forming a thin protective layer that improves corrosion resistance and provides a decorative finish. 4. Cladding: Cladding involves bonding a layer of corrosion-resistant material, such as stainless steel or titanium, to the surface of the special steel. This method provides enhanced resistance to corrosion, wear, and heat, while maintaining the strength and mechanical properties of the base steel. 5. Thermal spraying: This method involves heating a coating material, such as zinc or aluminum, to a molten or semi-molten state and then spraying it onto the steel surface using compressed air or a similar method. The sprayed material forms a protective layer that offers excellent corrosion resistance and can also provide other functional properties, such as thermal insulation or electrical conductivity. 6. Chemical conversion coating: This method involves treating the steel surface with a chemical solution that reacts with the surface to form a thin layer of a protective compound, such as phosphate or chromate. The conversion coating provides enhanced corrosion resistance and can also improve the adhesion of subsequent coatings. These are just a few of the many methods available for coating special steel. The choice of method depends on factors such as the desired properties, the intended application, and the budget constraints. It is important to select the most appropriate coating method to ensure the longevity and performance of the special steel.

- Q: What is the difference between special steel and regular steel?

- Special steel refers to a specific type of steel that has been enhanced with additional alloying elements or has undergone specialized treatments to enhance its strength, durability, or other desired properties. Regular steel, on the other hand, refers to common or standard steel that does not possess these additional features or improvements. The key difference lies in the composition and processing, as special steel is engineered to meet specific requirements for particular applications, such as high-temperature resistance, corrosion resistance, or increased hardness.

- Q: How does special steel perform in high-temperature mechanical fatigue conditions?

- Special steel, such as heat-resistant or high-temperature steel alloys, is specifically designed to excel in high-temperature mechanical fatigue conditions. It demonstrates superior resistance to thermal expansion, corrosion, and oxidation, allowing it to maintain its structural integrity and mechanical properties even at elevated temperatures. This type of steel exhibits excellent strength, toughness, and creep resistance under prolonged cyclic loading, making it a reliable material for applications in high-temperature mechanical fatigue conditions.

- Q: What are the main advantages of using special steel in the automotive racing industry?

- The main advantages of using special steel in the automotive racing industry are its high strength-to-weight ratio, exceptional durability, and excellent thermal conductivity. Special steel allows for the construction of lighter and stronger components, enhancing the overall performance and speed of racing vehicles. It also ensures greater safety for drivers by providing increased resistance to impact and fatigue. Furthermore, the superior thermal conductivity of special steel aids in dissipating heat generated during intense racing conditions, preventing overheating and maintaining optimal engine performance.

Send your message to us

Hot Dip Galvanized Steel Sheet/Z140 Galvanized Steel Coil

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords