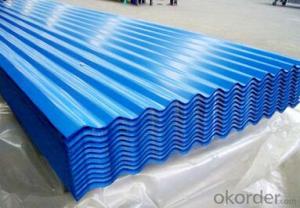

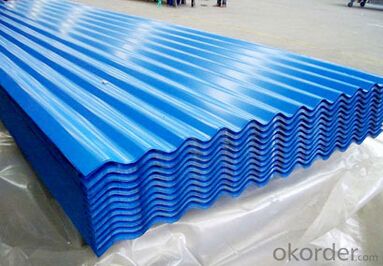

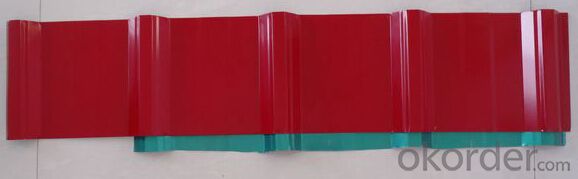

Best COATED GALVANIZED CORRUGATED STEEL SHEET

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

raw materials | SGCC |

thickness | 0.12-3.2mm |

width | 100-1500mm |

length | 500-12000mm |

model | CGCC,DX51D+Z,DX52D+Z,DX53D+Z,DX54D+Z,etc. |

use | roof structure,surface sheet of balcony,etc. |

surface paint | EP,PE,HDP,SMP,PVDF |

coating process | double coating double baking |

coating | high-grade polyester(PE) lacquer |

painting thickness | top side:12-25 microns,bottom side:5-10 microns |

zinc coating | 40-275g/m2 or as request |

PACKAGE: FULL WRAPPED ANTI-DAMP PAPER INSIDE, AND STEEL SHEET OUTSIDE IN 20'FCL.

SHIPMENT:WITHIN 30 DAYS AFTER RECEIPT OF ADVANCED PAYMENT

DOCUMENTS REQUIRED: 1,FULL SET(3/3) OF ORIGINAL CLEAN ON BOARD BILL OF LADING;2,ORIGINAL SIGNED COMMERCIAL INVOICE, IN 3 ORIGINALS AND 3 COPIES;3,ORIGINAL PACKING LIST IN 3 ORIGINALS AND 3 COPIES;

TERMS OF PAYMENT:30% ADVANCED PAYMENT BEFORE PRODUCTION,BALANCE BEFORE SHIPMENT

- Q: Are the steel sheets resistant to chemical spills?

- In general, steel sheets possess resistance against chemical spills. Steel is famous for its durability and capacity to endure different environmental conditions, including chemical exposure. The non-reactive properties of steel make it extremely resistant to corrosion, thereby providing effective protection against chemical spills. Nevertheless, the ability of steel sheets to resist chemical spills may vary depending on the type and concentration of the chemicals. To ensure the highest level of resistance, it is advisable to seek advice from experts or refer to specific steel grades and their compatibility with different chemicals.

- Q: What are the different sheet metal folding techniques for steel sheets?

- There are several sheet metal folding techniques that can be used for steel sheets. These techniques are commonly employed in various industries, such as automotive, aerospace, and construction, to create complex shapes and structures. Some of the most common sheet metal folding techniques for steel sheets include: 1. Box and Pan Folding: This technique involves bending the sheet metal along multiple parallel edges to create a box-like shape. It is commonly used to create enclosures, cabinets, and trays. 2. Hemming: Hemming is a technique used to fold the edges of a sheet metal component to increase its rigidity and eliminate sharp edges. It is often used in the automotive industry for creating panels and body parts. 3. Brake Press Folding: A brake press is a machine tool that utilizes a hydraulic or mechanical press to bend the sheet metal. It allows for precise and accurate folding by adjusting the angle and depth of the bend. Brake press folding is one of the most commonly used techniques in sheet metal fabrication. 4. Roll Forming: Roll forming is a continuous bending process where the sheet metal is passed through a series of rollers to gradually shape it into a desired profile. It is suitable for creating long and continuous shapes, such as tubes and channels. 5. Rotary Folding: In rotary folding, a rotating tool is used to fold the sheet metal along a curved or circular path. This technique is often used to create rounded edges, curves, and cylindrical shapes. 6. Folding Machines: Folding machines are specifically designed to fold sheet metal by applying pressure along a predetermined line. These machines can be programmed to perform various folding operations, including simple bends, complex shapes, and multiple folds. Each of these sheet metal folding techniques has its advantages and limitations, and the choice of technique depends on factors such as the complexity of the design, required precision, and production volume. Skilled craftsmen and specialized machinery are often employed to ensure accurate and efficient folding of steel sheets.

- Q: Are steel sheets suitable for oil rig platforms?

- Yes, steel sheets are suitable for oil rig platforms. Steel is widely used in the construction of oil rig platforms due to its exceptional strength and durability. Oil rig platforms are subjected to harsh environmental conditions, such as extreme temperatures, high winds, and corrosive saltwater, and steel has proven to be able to withstand these conditions effectively. Steel sheets provide a strong and stable foundation for the oil rig platforms, ensuring that they can support the weight of the rig, equipment, and personnel. The high strength of steel allows for the construction of large and complex structures while maintaining stability and safety. Furthermore, steel is highly resistant to corrosion, making it an ideal material for offshore applications. The oil rig platforms are constantly exposed to saltwater, which can cause corrosion and weaken other materials. Steel sheets, however, can be specially treated with protective coatings to enhance their resistance to corrosion and extend their lifespan. In addition to its strength and corrosion resistance, steel is also a versatile material that can be easily shaped and fabricated into various components required for oil rig platforms. This flexibility allows for efficient and cost-effective construction processes, reducing both time and resources required for installation and maintenance. Overall, steel sheets are a suitable choice for oil rig platforms due to their strength, durability, corrosion resistance, and versatility. They provide a reliable and robust foundation for offshore drilling operations, ensuring the safety and longevity of the platform in challenging environments.

- Q: What is the weight of a typical steel sheet?

- The dimensions and thickness of a steel sheet can cause fluctuations in its weight. Nevertheless, for a rough approximation, a commonly employed steel sheet in construction and manufacturing, measuring 4' x 8', usually weighs approximately 80 to 100 pounds (36 to 45 kilograms). It is crucial to acknowledge that this weight can vary based on the specific steel type and its gauge or thickness.

- Q: Can steel sheets be used for manufacturing electronics?

- Yes, steel sheets can be used for manufacturing certain electronic components such as chassis and enclosures, as they provide durability and protection. However, they are not commonly used for the internal circuitry or sensitive electronic parts due to their magnetic properties and conductivity limitations compared to other materials like copper or aluminum.

- Q: What are steel sheets made of?

- Steel sheets are made of a combination of iron and carbon, along with other elements such as manganese, nickel, and chromium, which are added to enhance the strength and durability of the steel.

- Q: Can steel sheets be used for electrical enclosures?

- Yes, steel sheets can be used for electrical enclosures. Steel is a commonly used material due to its durability, strength, and ability to provide electromagnetic shielding. It is suitable for protecting electrical components from external factors such as moisture, dust, and impact while also providing a safe and secure environment for the electrical equipment.

- Q: Can steel sheets be used for cladding or façade applications?

- Yes, steel sheets can be used for cladding or façade applications. Steel is a versatile and durable material commonly used in construction for its strength and aesthetic appeal. Steel sheets can be easily fabricated into various shapes and sizes, making them suitable for cladding or covering building exteriors. Additionally, steel sheets can be coated or treated to enhance their resistance to corrosion and weathering, further making them a suitable choice for cladding or façade applications.

- Q: Can steel sheets be etched or engraved?

- Yes, steel sheets can be etched or engraved using various techniques such as chemical etching, laser engraving, or mechanical engraving.

- Q: How do steel sheets perform under heavy loads or pressure?

- Steel sheets are known for their exceptional strength and durability, making them highly resistant to heavy loads or pressure. Due to their composition and manufacturing process, steel sheets possess a high tensile strength, which allows them to withstand substantial amounts of force without deforming or breaking. This property makes steel sheets ideal for applications where heavy loads or pressure are involved, such as construction, transportation, and industrial machinery. Additionally, steel sheets have excellent load-bearing capacity, meaning they can distribute the applied pressure evenly across their surface, minimizing the risk of structural failure or damage. The ability of steel sheets to perform under heavy loads or pressure is further enhanced by their rigidity, which prevents them from bending or buckling, ensuring the integrity of the structure or equipment they are supporting. Overall, steel sheets are a reliable and robust choice when it comes to handling heavy loads or pressure, making them a popular material in various industries.

Send your message to us

Best COATED GALVANIZED CORRUGATED STEEL SHEET

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords