Hot-Dip Galvanized Steel Roof of High Quality with Different Thickness

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Hot-Dip Galvanized Steel Roof Description:

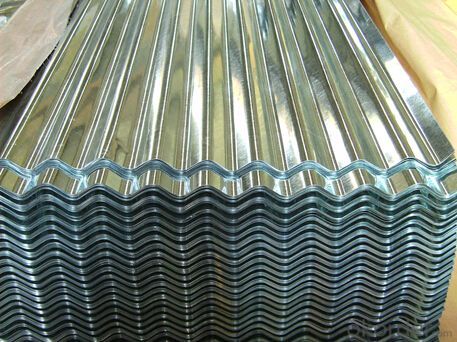

Hot-dip galvanized steel roof are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial application.

2.Main Features of the Hot-Dip Galvanized Steel Roof:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

3.Hot-Dip Galvanized Steel Roof Images

4.Hot-Dip Galvanized Steel Roof Specification

Material: Galvanized Sheet

Width: 650/800/890/900

Length: 1500/1800/2000/2400/3005/3600 or customized

Thickness: 0.2-2.0

Surface Treatment: Hot dipped/Bended

Application: warehouse; shelter; Commercial facilities; industrial facilities

5.FAQ of Hot-Dip Galvanized Steel Roof

Which payment term we can do?

L/C at sight or T/T.

What’s the basic material of this product?

Galvanized/Aluzinc Steel

What’s the coating composition of Hot-Dip Galvanized Steel Coil?

The coating composition is 55% aluminium in weight ratio, 43.4% zinc, and 1.5% silicon, with excellent corrosion and heat resistance performance.

- Q: What is the maximum temperature that steel coils can withstand?

- The maximum temperature that steel coils can withstand depends on the specific type of steel being used. However, generally, steel coils can withstand temperatures up to around 1,500 degrees Fahrenheit (815 degrees Celsius) before they begin to lose their structural integrity and strength.

- Q: How are steel coils secured during transportation?

- Steel coils are typically secured during transportation using steel strapping, bands, or wire rope. These securements help prevent the coils from shifting or falling off the transportation vehicle, ensuring their safe delivery to the destination.

- Q: How are steel coils used in the manufacturing of industrial filters?

- Steel coils are used in the manufacturing of industrial filters as a primary material for constructing the filter frames and support structures. The coils are typically cut, shaped, and welded to create the necessary framework that holds the filter media and allows for efficient filtration. The strength and durability of steel make it an ideal choice for withstanding the pressure and demands of industrial filtration processes.

- Q: What are the different coil leveling methods used for steel coils?

- There are several coil leveling methods used for steel coils, each with its own benefits and limitations. Here are some of the most common methods: 1. Roller Leveling: In this method, steel coils are passed through a series of rollers that apply pressure to flatten and level the coils. Roller leveling is effective in reducing coil crown or center buckle, and it can also help eliminate coil memory. However, it may not be suitable for coils with severe shape defects or variations. 2. Stretch Leveling: This method involves stretching the steel coils to remove any shape defects. The coils are passed through a series of gripper heads that hold the edges of the coil while it is stretched. Stretch leveling is particularly effective in correcting crossbow and edge wave defects. However, it may cause some elongation and yield loss in the material. 3. Temper Pass: This method involves passing the steel coils through a series of temper mill stands, where they are subjected to tension and compression forces. Temper pass leveling helps improve flatness and remove coil memory. It is commonly used for thinner gauge steel coils but may not be suitable for thicker coils. 4. Corrective Leveling: This method is used for coils with severe shape defects. It involves selectively removing material from specific areas of the coil to correct the shape. Corrective leveling is a labor-intensive process that requires skilled operators, but it can effectively eliminate shape defects and improve flatness. 5. Tension Leveling: In this method, the steel coils are subjected to tension forces while being passed through a series of pinch rolls. Tension leveling helps remove coil memory and improve flatness. It is particularly effective for coils with edge wave defects. However, it may cause some elongation and yield loss in the material. These are just a few of the coil leveling methods used for steel coils. The choice of method depends on the specific requirements of the steel coils and the desired flatness results. It is important to consider factors such as material thickness, shape defects, and production capacity when selecting the appropriate leveling method.

- Q: What are the common methods of forming steel coils?

- There are several common methods for forming steel coils, each with its own unique advantages and applications. The most common method is known as hot rolling. This involves heating a large steel slab to a high temperature and passing it through a series of rollers to reduce its thickness. The steel is then coiled into a large, continuous roll. Hot rolling is typically used for producing steel coils with a consistent thickness and a smooth surface finish. It is commonly used in industries such as automotive, construction, and manufacturing. Another method is cold rolling, which is similar to hot rolling but is performed at room temperature. Cold rolling involves passing the steel through a set of rollers to further reduce its thickness and improve its surface finish. This process is often used to produce steel coils with precise dimensions and excellent mechanical properties. Cold-rolled steel coils are commonly used in applications that require high strength, such as in the production of appliances, electrical components, and structural components. A third method is known as galvanizing. This involves coating the steel coil with a layer of zinc to protect it from corrosion. The steel coil is first cleaned and then immersed in a bath of molten zinc. The zinc adheres to the surface of the steel, forming a protective layer. Galvanized steel coils are widely used in outdoor applications, such as roofing, fencing, and automotive parts, due to their excellent corrosion resistance. Lastly, there is the electro-galvanizing method. This process involves applying a thin layer of zinc to the surface of the steel coil through an electroplating process. The steel coil is immersed in an electrolyte solution and an electric current is passed through it, causing the zinc to deposit onto the surface of the steel. Electro-galvanized steel coils are commonly used in industries that require a smooth and aesthetically pleasing finish, such as in the production of appliances, automotive parts, and decorative items. Overall, these common methods of forming steel coils provide a wide range of options for different applications and requirements. Whether it is hot rolling, cold rolling, galvanizing, or electro-galvanizing, each method offers unique benefits in terms of strength, durability, surface finish, and corrosion resistance.

- Q: When i was 15 i got caught steeling at Super A yes i know i cant believe it. They didnt call the cops or anything they released me to my aunt they took my name and adress and everythimg they said it wouldnt be on my record. But I'm not so sure. Will it be on my record if they didn't call the cops?i live in california. Is there any way i can check my record?

- Steeling? What's that? Did you take a piece of steel and weld it? I am confused?

- Q: Hi my dad bought a stain steel refridg. yesterday, and we went to clean it and it looks all streaky and gets finger prints and stuff on it too easily we used mr clean multisurface cleaner and it didnt work to well is there a certain type of cleaner we are supposed to use?

- Stainless Steel Magic works well. If there are no small kids in the house, use a little bit of WD-40 to get some of the bad stuff off, it will shine it up really well. It's not an everyday solution, but it works. Stainless Steel will always pick up fingerprints. There's not much you can do about that.

- Q: How are steel coils used in the manufacturing of automotive doors?

- Steel coils are used in the manufacturing of automotive doors by being processed and shaped into sheets that are then stamped, cut, and formed to create the door's structure. The strength and durability of steel make it an ideal material for automotive doors, ensuring safety and protection for passengers.

- Q: What are the common methods of testing the strength of steel coils?

- Steel coils can be tested for strength using various methods. Tensile testing is one such method, which involves applying tension to the coil until it breaks. This test provides information about the coil's ability to withstand force and its tensile strength. It also reveals details about its yield strength and elongation properties. Another common method is hardness testing, which determines the steel's resistance to indentation or scratching. Different techniques like Rockwell, Brinell, or Vickers tests are utilized to measure hardness. This test helps determine the steel's ability to resist wear or deformation. To evaluate the coil's ductility and flexibility, bend testing is performed. The coil is bent to a specific angle and checked for any signs of cracking or fracturing. Bend testing assesses the material's capacity to withstand bending or forming procedures without failure. Additional methods of testing include impact testing, where controlled impacts are applied to assess the coil's resistance to sudden loading conditions, and fatigue testing, which involves subjecting the coil to cyclic loading to determine its endurance limit and potential for failure under repeated stress. It is important to note that the specific testing methods used may vary depending on the intended application and industry standards. Non-destructive testing techniques, such as ultrasonic testing or magnetic particle inspection, can also be employed to detect internal defects or flaws in steel coils without causing any damage.

- Q: How are steel coils used in the production of wind turbines?

- Steel coils are used in the production of wind turbines to manufacture the tower, nacelle, and other structural components. The coils are processed and shaped to form the required sections, which are then assembled and integrated to create the framework and support structure for the wind turbine. The high strength and durability of steel make it an ideal material for withstanding the demanding conditions and loads experienced by wind turbines.

Send your message to us

Hot-Dip Galvanized Steel Roof of High Quality with Different Thickness

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords