Hot-Dip Galvanized Steel Roof Good Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m

- Supply Capability:

- 10000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Hot-Dip Galvanized Steel Roof Description:

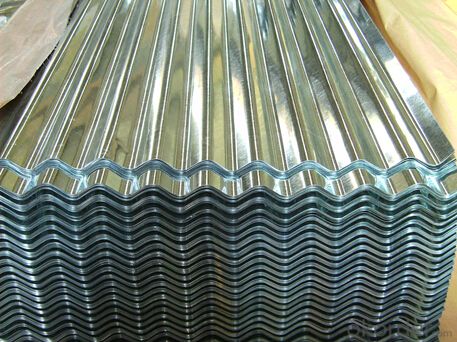

Hot-dip galvanized steel roof are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial application.

2.Main Features of the Hot-Dip Galvanized Steel Roof:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

3.Hot-Dip Galvanized Steel Roof Images

4.Hot-Dip Galvanized Steel Roof Specification

Material: Galvanized Sheet

Width: 650/800/890/900

Length: 1500/1800/2000/2400/3005/3600 or customized

Thickness: 0.2-2.0

Surface Treatment: Hot dipped/Bended

Application: warehouse; shelter; Commercial facilities; industrial facilities

5.FAQ of Hot-Dip Galvanized Steel Roof

Which payment term we can do?

L/C at sight or T/T.

What’s the basic material of this product?

Galvanized/Aluzinc Steel

- Q: How are steel coils used in the manufacturing of household goods?

- Steel coils are commonly used in the manufacturing of household goods as they are shaped and processed into various components such as frames, springs, and supports. These coils provide strength, durability, and stability to items like furniture, appliances, and automotive parts, ensuring their longevity and functionality.

- Q: Where can I find a discount online for Stainless Steel Magnetic Knife Rack

- MIU Stainless-Steel Magnetic Knife Holder List Price: $39.99 Price: $27.99 this item ships for FREE with Super Saver Shipping. Details You Save: $12.00 (30%) Product Features * Magnetic for secure hold on knives * Contemporary design * Encased in attractive 18/10 stainless steel * Measures 20 inches long, ? inch wide, 2 inches thick * 20-inch Length x .75-inch Height x 2-inch Width Product Details * Product Dimensions: 23.6 x 5.4 x 3.2 inches ; 3.8 pounds * Shipping Weight: 4 pounds (View shipping rates and policies) * Shipping: This item can only be shipped to the 48 contiguous states. We regret it cannot be shipped to APO/FPO, Hawaii, Alaska, or Puerto Rico. * Shipping Advisory: This item must be shipped separately from other items in your order. Additional shipping charges will not apply. * ASIN: B0000DZDHB * Item model number: 90009 Product Description Stainless Steel 20-inch Magnetic Knife Holder

- Q: How are steel coils processed for heat treatment?

- Steel coils are typically processed for heat treatment by first being uncoiled and then cleaned to remove any dirt or scale. The coils are then heated to a specific temperature, which is determined based on the desired properties of the steel. This temperature is maintained for a specific period of time to allow for the desired transformation of the steel's microstructure. After the heat treatment process is complete, the coils are cooled either slowly or rapidly, depending on the desired properties. This allows the steel to be hardened or softened as required. Finally, the coils are recoiled and prepared for further processing or shipment.

- Q: A roll of 1 meters wide color steel roll about how many tons?

- Generally speaking, it will be about 4 tons, the export may be larger, but 10 tons of papers have not yet seen

- Q: What website can I use to find a good picture that shows the atomic structure of a carbon steel?

- You know, I'd have to say it's very complex.

- Q: What are the common coil defects and their causes?

- Common coil defects can include misshapen coils, coil breaks, and coil slippage. Misshapen coils can be caused by improper winding tension or uneven material thickness. Coil breaks may occur due to excessive tension during winding, inadequate material strength, or improper handling. Coil slippage can result from insufficient binding or improper tension control. These defects can affect the performance and integrity of the coil, leading to potential issues in its functionality.

- Q: The knife will be large and thick. Like the Bowie knife Rambo uses in Rambo III. It doesn't need to be flexible or to hold the edge very well. But i need it to be exceptionally strong material and to stop corrosion at least decently. Is Damascus Steel good?Thank you, in advance.

- If it does not could desire to hold an part o.k. then 440 stainless could be your appropriate guess. I want severe carbon steel. yet they require alot of cleansing and oiling or they're going to rust.

- Q: How are steel coils used in the manufacturing of railway equipment?

- Steel coils are used in the manufacturing of railway equipment as they are transformed into various components such as rail tracks, train wheels, and structural frames. These coils are processed through rolling mills to achieve the desired shape and strength required for the specific railway equipment.

- Q: With the Reduced weight of steel,wouldn't the projectile be at a much higher velocity when fired causing more damage?I mean l couldn't steel be worked to seal the bore,not damage the rifling and still cheap enough to mass produce,and be light enough to carry much more ammo.

- Okay one side note before going into the main issue. Steel is really really hard on rifle barrels. Okay, so the most common lead 9mm bullet weighs 124 grains. If all that was wanted was higher velocity, you could switch to a 115 grain bullet (which some people do), or even a 90 grain bullet if you are a reloader. (You see 90 grain bullets for 380 acp ammo, that same bullet could be reloaded onto a 9mm cartridge) But velocity alone doesn't give power. That's why a 115 grain 9mm bullet going at it's standard velocity does less damage than a 45 acp's 230 grain bullet going at it's standard velocity, because it weights twice as much and yet is going only a little bit slower But now go out to your front yard and grab a ping-pong ball and a rock about the same size. Throw them both as hard as you can. The ping-pong ball while lighter didn't go very far did it. See, the ratio of surface area to overall weight of ping-pong ball is very high, so air resistance works on it a LOT. And that is what makes lead so great for projectiles. It is dense so you have a very small surface area per unit of weight meaning that a steel bullet may beat lead in initial velocity but just 50 feet out the lead bullet would be going pretty much the same speed and at 100 yards out the steel would be dramatically slower. Note this is the same reason why 'secret sniper ice bullets' would never work even if you could get it to not melt...it's just too light. Ever hear of tanks and airplanes firing DU ammo? That stands for Depleted Uranium, it is something that is even more dense than lead which is why it makes an even better bullet than lead

- Q: What are the different methods of edge trimming for steel coils?

- There are several methods of edge trimming for steel coils, depending on the specific requirements and application. Some of the common methods include: 1. Slitting: This is one of the most common methods used to trim the edges of steel coils. It involves passing the coil through a set of circular knives that cut the edges into narrower strips. Slitting can be done in-line during the manufacturing process or as a separate operation. 2. Shearing: Shearing is another popular method used for edge trimming. It involves using a set of blades to cut the edges of the coil in a straight line. Shearing is often used when precise and clean cuts are required, and it can be done manually or with the help of automated machinery. 3. Laser cutting: Laser cutting is a more advanced method that uses a high-powered laser to trim the edges of steel coils. This method provides precise and smooth cuts, and it is often used when high accuracy and quality are essential. Laser cutting can be incorporated into the production line or performed as a standalone process. 4. Grinding: Grinding is a method that involves using abrasive wheels or belts to remove material from the edges of steel coils. It is commonly used to remove burrs, rough edges, or surface imperfections. Grinding can be done manually or with the help of automated machines, depending on the scale and complexity of the trimming process. 5. Waterjet cutting: Waterjet cutting is a method that utilizes a high-pressure jet of water mixed with abrasive particles to trim the edges of steel coils. This method is known for its versatility and ability to cut through a wide range of materials and thicknesses. Waterjet cutting is typically used when complex shapes or intricate designs need to be achieved. Overall, the choice of edge trimming method for steel coils depends on factors such as the desired accuracy, speed, complexity of the edges, and the specific requirements of the application. Different methods offer varying levels of precision, efficiency, and cost-effectiveness, allowing manufacturers to select the most suitable technique for their specific needs.

Send your message to us

Hot-Dip Galvanized Steel Roof Good Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m

- Supply Capability:

- 10000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords