Hot-Dip Galvanized Steel Roof with HIgh Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Hot-Dip Galvanized Steel Roof Description:

Hot-dip galvanized steel roof are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial application.

2.Main Features of the Hot-Dip Galvanized Steel Roof:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

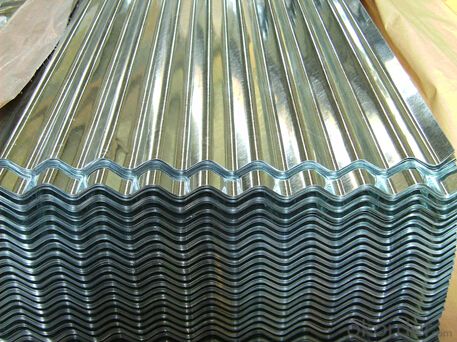

3.Hot-Dip Galvanized Steel Roof Images

4.Hot-Dip Galvanized Steel Roof Specification

Material: Galvanized Sheet

Width: 650/800/890/900

Length: 1500/1800/2000/2400/3005/3600 or customized

Thickness: 0.2-2.0

Surface Treatment: Hot dipped/Bended

Application: warehouse; shelter; Commercial facilities; industrial facilities

5.FAQ of Hot-Dip Galvanized Steel Roof

Which payment term we can do?

L/C at sight or T/T.

What’s the basic material of this product?

Galvanized/Aluzinc Steel

- Q: How do steel coils impact the environment?

- Steel coils impact the environment in several ways. Firstly, the production of steel coils requires large amounts of energy and resources, leading to increased greenhouse gas emissions and depletion of natural resources. Additionally, the manufacturing process generates air and water pollution, contributing to environmental degradation. Furthermore, the disposal of steel coils after use can result in land pollution if not properly managed. Overall, the production and use of steel coils have a significant environmental footprint.

- Q: 7850kg/cu.m density is typical for all type of steel? like reibar, I- beam and so on

- 90% of the steels used today are plain mild carbon steels consisting of iron with less than 1% carbon content and as such have a density of about 7750 kg/cubic meter. Some special steels which have a significant percentage of alloying elements such as chrome or manganese or other elements will have greater density bringing the steel up to about 8000 kg / cubic meter. There are a greater many factors influencing the exact density of a steel. Even for steels of exactly the same content of iron , carbon and other alloying elements, there may be a difference ( very small mind you ) in density due to work hardening. The difference in this case is due to movement of dislocations which become locked in the grain boundaries and this forms a more dense crystal structure. For this same reason, the theoretical density of steel (which does not take into account dislocations) is greater than the measured density of steel.

- Q: What are the common methods of packaging steel coils for international shipping?

- Various techniques are employed to package steel coils for international shipment in order to guarantee their safety and security during transit. One approach involves the utilization of wooden crates. Steel coils are positioned on wooden pallets and fastened with steel bands or straps. Next, wooden boards or plywood are placed over the coils and firmly attached with nails or screws to create a robust crate. This method ensures exceptional protection against damage and guarantees that the coils remain fixed in place during transportation. Another option is to employ steel frames or skids. Steel coils are positioned on specially designed steel skids or frames that can support the weight and shape of the coils. These coils are then secured to the skids or frames using steel bands or straps. This method offers a high level of stability and protection, making it particularly suitable for larger or heavier coils. In addition to wooden crates and steel frames, steel coils can also be packaged using steel containers or shipping containers. These containers are specifically designed to transport heavy or bulky items and provide a secure and protective environment for the coils. The coils are loaded into the container and secured with steel bands or straps to prevent movement during transit. Regardless of the chosen packaging method, it is crucial to ensure that the steel coils are adequately shielded from moisture, corrosion, and other potential hazards. This may involve the use of moisture-resistant materials such as plastic or wax paper, as well as the application of protective coatings or wraps. In summary, the common methods of packaging steel coils for international shipping include wooden crates, steel frames or skids, and steel containers. The selection of these methods depends on factors such as the size, weight, and specific requirements of the coils, with the ultimate goal of providing maximum protection and security during transit.

- Q: How is the thickness of a steel coil measured?

- The thickness of a steel coil is typically measured using a gauge, which is a specialized tool specifically designed for measuring the thickness of materials. The gauge is pressed against the coil, and the reading on the gauge indicates the thickness of the steel.

- Q: How are steel coils coated?

- Steel coils are coated through a process called coil coating, where the steel is cleaned, treated, and then coated with a protective layer using techniques such as roll coating or spray coating.

- Q: What are the different methods of coil welding for steel coils?

- There are several different methods of coil welding for steel coils, including resistance welding, laser welding, and induction welding. Resistance welding involves applying pressure and passing an electrical current through the coils to create a weld. Laser welding utilizes a high-powered laser beam to melt and fuse the edges of the coils together. Induction welding involves using electromagnetic fields to heat and fuse the coils. Each method has its own advantages and is chosen based on the specific requirements of the application.

- Q: Can you suggest me names of sites which aids in construction of Pre Fabricated Steel Buildings.

- A word of caution, there are many bad steel building contractors out there. Stay with reputable brands such as Butler, Behlen, and Whirlwind. A broker such as Heritage will get you good results but I have heard horror stories about a lot of steel building brokers.

- Q: What is the lifespan of a steel coil?

- The lifespan of a steel coil can vary depending on various factors such as the quality of the steel, its usage and maintenance. However, on average, a well-maintained steel coil can last anywhere from 10 to 30 years.

- Q: I need to know the density of steel as one of my physical properties of steel. Any answers? If u have more physical or chemical properties of steel, that would help to thanks.

- This Site Might Help You. RE: What is the density of steel? I need to know the density of steel as one of my physical properties of steel. Any answers? If u have more physical or chemical properties of steel, that would help to thanks.

- Q: How are steel coils used in the manufacturing of airbags?

- Steel coils are used in the manufacturing of airbags to provide structural support and stability. These coils are typically incorporated into the airbag module, helping to maintain its shape and ensure proper deployment in the event of a collision.

Send your message to us

Hot-Dip Galvanized Steel Roof with HIgh Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords