Hot-Dip Galvanized Steel Coil Used for Industry with Our Good Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot-Dip Galvanized Steel Coil Used for Industry

1.Structure of Hot-Dip Galvanized Steel Coil Description

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc.

2.Main Features of the Hot-Dip Galvanized Steel Coil

•High Purity

•Easy control and operation

•High strength

•Fast melting

•Competitive price

•Best Service

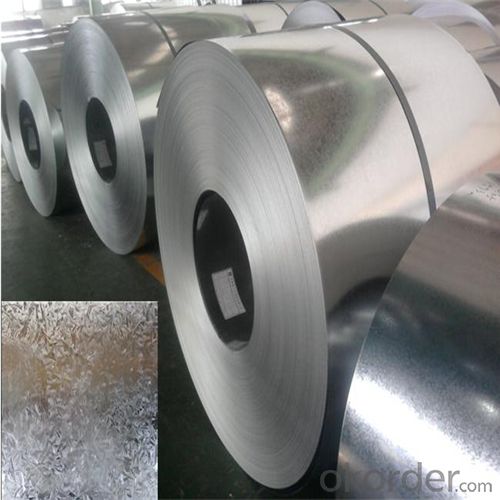

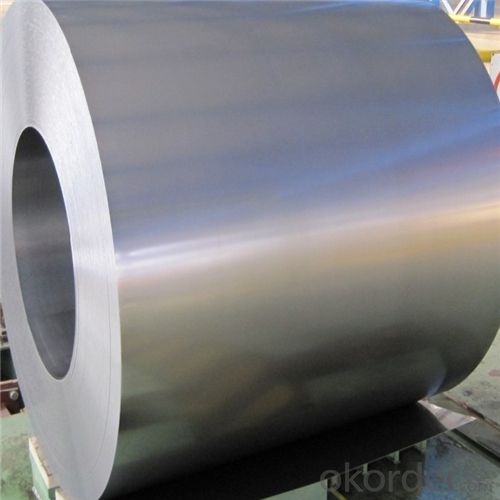

3. Hot-Dip Galvanized Steel Coil Images

4. Hot-Dip Galvanized Steel Coil Specification

Hot-Dip Galvanized Steel Coil | |

Thicknenss | 0.10mm-5.00mm |

Width | 2000mm max |

Coating mass | 30-600g/㎡ |

Spangle | Regular/Minimized/Zero Spangle |

Coil inner diameter | 508-610mm |

Surface treatment | Chromated/non chromated, Oiled/non oiled, Anti finger print |

5.FAQ of Hot-Dip Galvanized Steel Coil

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: What is the maximum width of a steel coil?

- The maximum width of a steel coil can vary depending on the manufacturing process and the specific requirements of the industry. However, in general, steel coils can have a maximum width of around 2,200 millimeters (86.6 inches).

- Q: How are steel coils used in the manufacturing of storage shelves?

- Steel coils are used in the manufacturing of storage shelves by being cut and shaped into the desired size and design. The coils are typically processed through a roll forming machine which bends and molds the steel into the required shape for the shelves. This process allows for high efficiency and precision in creating uniform and durable storage shelves.

- Q: hello friends, I have some old 7.62x54r on stripper clips its nasty gunk on it can i use steel wool to glean it and still have it fire safely?

- You could, but if you have access to a vibrating case tumbler, it would work much better. I just tumbled a batch of 1,000 of tarnished and dirty Romanian 7.62X25 and it now looks like brand new commercial ammo.

- Q: How are steel coils inspected for damage during transportation?

- Steel coils are typically inspected for damage during transportation through visual inspections, where trained personnel carefully examine the coils for any visible signs of dents, scratches, or other forms of physical damage. Additionally, specialized equipment such as ultrasonic testing or magnetic particle inspection may be used to identify any hidden or internal defects in the coils. These inspection methods ensure that any potential damage is detected early on, allowing for prompt repairs or necessary precautions to minimize any further harm.

- Q: Can steel coils be reused?

- Yes, steel coils can be reused. Steel is a highly recyclable material, and steel coils can be melted down and used to produce new steel products. Recycling steel coils not only helps to conserve resources and reduce waste but also contributes to a more sustainable and environmentally-friendly manufacturing process.

- Q: What is the average lifespan of a steel coil storage rack?

- The average lifespan of a steel coil storage rack can vary depending on various factors such as the quality of the rack, the frequency and intensity of use, and proper maintenance. However, a well-maintained and durable steel coil storage rack can typically last for several decades.

- Q: How are steel coils used in the production of agricultural storage tanks?

- Steel coils are used in the production of agricultural storage tanks as they serve as the primary material for constructing the tank walls and base. The coils are shaped and welded together to form a sturdy and durable structure that can withstand the weight and pressure of storing agricultural products such as grains, feed, and fertilizers. The steel coils provide the necessary strength and corrosion resistance required for long-term storage in various agricultural environments.

- Q: How are steel coils used in the agricultural industry?

- Steel coils are commonly used in the agricultural industry for various purposes, such as manufacturing equipment like plows, harrows, and cultivators. They are also used for constructing storage structures like grain bins, as well as fencing and livestock enclosures. Additionally, steel coils are used in the construction of agricultural machinery and vehicles, ensuring durability and strength in demanding farming conditions.

- Q: hi, i have a steel block with an unussual composition. does anyone know if this is any particular type?c- .6%, si - .33%, mn - .6%, sulphur - .014%, phosphorous - .013%, ni - 1.69%, Cr, 1.07%, molybdenum - .67%

- You have opened a can of worms. Specific types of steel vary not only by composition but by the way they were made, their physical properties and their morphology (microscopic structure). The composition you have given would fit for High Carbon Steel and Medium Carbon Steel. Go to the reference I've given, it allows you to put in 3 of the components of your alloy and then it gives you a list of possibilities. You can open each candidate individually and see the full composition. Hours of fun. :)

- Q: How are steel coils used in the manufacturing of metal structures?

- Steel coils are commonly used in the manufacturing of metal structures as they provide a convenient and efficient way to shape and form various components. These coils are unrolled and then processed through machinery that cuts, bends, and shapes the steel into the desired size and shape. This allows for precise and consistent fabrication, making it easier to assemble and construct metal structures such as buildings, bridges, and machinery.

Send your message to us

Hot-Dip Galvanized Steel Coil Used for Industry with Our Good Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords