Hot-Dip Galvanized Steel Coil Used for Industry with Very Good Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

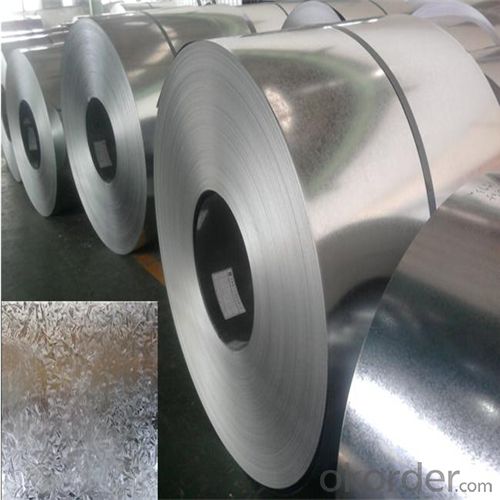

Hot-Dip Galvanized Steel Coil Used for Industry

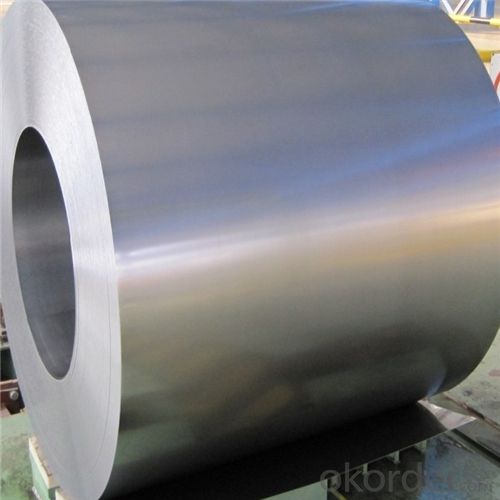

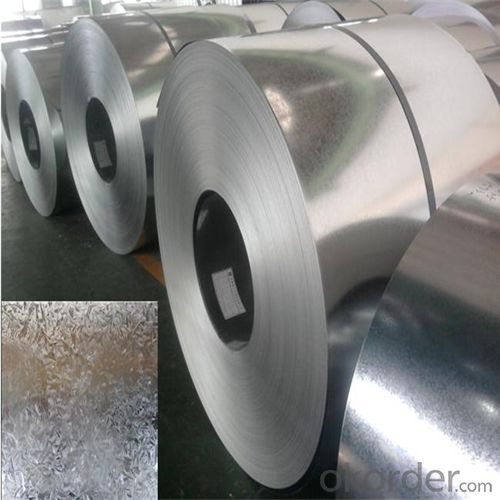

1.Structure of Hot-Dip Galvanized Steel Coil Description

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful countless outdoor and industrial applications.

2.Main Features of the Hot-Dip Galvanized Steel Coil

•High Purity

•Easy control and operation

•High strength

•Fast melting

•Competitive price

•Best Service

3. Hot-Dip Galvanized Steel Coil Images

4. Hot-Dip Galvanized Steel Coil Specification

Hot-Dip Galvanized Steel Coil | |

Thicknenss | 0.10mm-5.00mm |

Width | 2000mm max |

Coating mass | 30-600g/㎡ |

Spangle | Regular/Minimized/Zero Spangle |

Coil inner diameter | 508-610mm |

Surface treatment | Chromated/non chromated, Oiled/non oiled, Anti finger print |

5.FAQ of Hot-Dip Galvanized Steel Coil

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: Is steel harder than iron or is iron harder than steel?Please explain... and help!Thanks

- steel is harder than iron Iron is a chemical element. It is a strong, hard, heavy gray metal. It is found in meteorites. Iron is also found combined in many mineral compounds in the earth's crust. Iron rusts easily and can be magnetized and is strongly attracted to magnets. It is used to make many things such as gates and railings. Iron is also used to make steel, an even harder and tougher metal compound. Steel is formed by treating molten (melted) iron with intense heat and mixing it (alloying) with carbon. Steel is used to make machines, cars, tools, knives, and many other things.

- Q: How do steel coils contribute to the HVACR equipment industry?

- Steel coils are an essential component in the HVACR equipment industry as they are used in various applications such as heat exchangers, condenser coils, and evaporator coils. These coils provide a durable and efficient solution for transferring heat, ensuring optimal performance and energy efficiency of HVACR systems. Additionally, steel coils offer excellent corrosion resistance, allowing them to withstand harsh environmental conditions and extend the lifespan of the equipment. Overall, steel coils play a crucial role in enhancing the functionality and longevity of HVACR equipment.

- Q: What are the different grades of steel used for making coils?

- When making coils, various grades of steel are commonly utilized, depending on specific requirements and applications. Some frequently employed grades are: 1. Mild steel, also referred to as low carbon steel, is often employed for coil production due to its favorable characteristics of formability, weldability, and machinability. It is suitable for diverse applications where strength and durability are not the primary concerns. 2. High carbon steel, which contains elevated carbon levels, offers increased strength and hardness. This grade is commonly used for coils that require high strength and resistance to wear, such as springs and automotive components. 3. Stainless steel, characterized by a high chromium content, exhibits excellent corrosion resistance. Coils made from stainless steel are commonly utilized in applications where resistance to rust and staining is critical, such as kitchen appliances, automotive trim, and medical equipment. 4. Galvanized steel, coated with a layer of zinc, provides exceptional corrosion resistance. Galvanized steel coils find common use in outdoor applications that involve exposure to moisture and other elements, including roofing, fencing, and HVAC ductwork. 5. Electrical steel, specifically designed for electrical applications like transformers, motors, and generators, possesses low impurity levels and is optimized for high magnetic permeability and low core loss. 6. Advanced high-strength steel (AHSS), engineered to offer exceptional strength while maintaining good formability, is frequently employed in the automotive industry. AHSS coils contribute to lightweighting vehicles while ensuring structural integrity and crashworthiness. These examples represent only a fraction of the steel grades employed in coil manufacturing. The choice of a specific grade depends on factors such as the intended application, desired properties, and cost considerations.

- Q: How are steel coils used in the automotive industry?

- Steel coils are used in the automotive industry to manufacture various components, such as body panels, frames, and suspension parts. These coils are transformed into flat sheets or molded into different shapes to meet the specific requirements of each component. The high strength and durability of steel make it an ideal material for ensuring safety and structural integrity in vehicles.

- Q: hello, just wondering if there is such a thing as a stainless steel coating for my aluminum muffler prior to installation. Yes, i suppose you can say that im cutting corners, but my current finances wont allow me to pay full price for a stainless steel one, thnx

- No stainless steel, I'm afraid, but there is an aerosol spray that a lot of welders use . It's a galvanic spray compound to coat weld joints to keep from rusting. It's silver in color, and my add a little 'pop' that it seems you are looking for. Also heat tolerant, and can be re-applied. Most welding supply stores carry this item, and look to pay around $12 a can. Good luck!

- Q: Have spent two days making a specialized knife out of 304 stainless steel, after throwing into a log it bent slightly arghhhh. Is it worth continuing to finish it off or start all over again with different kind of steel if so which kind should i use.

- Stainless Steel For Knife Making

- Q: What are the common coil diameters available for steel coils?

- The common coil diameters available for steel coils vary depending on the specific industry and application. However, some of the most common coil diameters for steel coils typically range from 24 inches to 72 inches. These diameters are often used in various sectors such as automotive, construction, and manufacturing. It is important to note that the specific coil diameter required may differ based on factors such as the size and weight of the material being coiled, the equipment being used to handle the coils, and the specific requirements of the end-use application.

- Q: I'm analysing horse stirrups and would like to know the disadvantages to stainless steel? - thanks

- Stainless Steel has more advantages than disadvantages. But u asked for disadvantages so they r as follows i've given common disadvantages more can be found on Google. Disadvantages of Stainless Steel: Stainless steel tends to scratch and dent. Food, grease and fingerprints show very clearly on stainless steel, making frequent wiping and cleaning a necessity. High initial cost Difficult to fabricate, or in other words, it is not as malleable as other metals, say iron, and hence if not fabricated properly, results in costly re-work. Difficult to weld High cost of polishing etc. i.e. adding finishing touches for the market. there are advantages more than disadvantages. But u asked for disadvantages that's why i have given only disadvantages of stainless steel Hope what u want u got.

- Q: How are steel coils protected from humidity?

- Steel coils are typically protected from humidity through a process called galvanization, where a layer of zinc or another protective coating is applied to the surface of the steel. This coating acts as a barrier, preventing moisture from coming into direct contact with the steel and minimizing the risk of corrosion. Additionally, steel coils are often stored in dry, enclosed spaces or wrapped with moisture-resistant materials such as plastic or wax paper to further protect them from humidity.

- Q: Can one assume that stainless steel that can be hardened is magnetic?

- actually stain less steel is mainlly three first one is austenitic, 2nd one is ferritic, and 3rd is martensitic. These three types of steels are identified by their microstructure or predominant crystal phase. Austenitic. Austenitic steels have austenite as their primary phase (face centered cubic crystal). These are alloys containing chromium and nickel (sometimes manganese and nitrogen), structured around the Type 302 composition of iron, 18% chromium, and 8% nickel. Austenitic steels are not magnetic and not hardenable by heat treatment. The most familiar stainless steel is 304 containing 18-20% chromium and 8-10% nickel. Ferritic. Ferritic steels have ferrite (body centered cubic crystal) as their main phase. These steels contain iron and chromium. Ferritic steel is somewhat magnetic, less ductile than austenitic steel, and is not hardenable by heat treatment. Martensitic. Martensitic steels have orthorhombic martensite as their main phase. Martensitic steels are low carbon steels. They are magnetic, and may be tempered and hardened. Martensite gives steel great hardness, but it also reduces its toughness and makes it brittle. If you ran around the house with a magnet, checking on the items you know are stainless steel, you would probably find that cookware and flatware are not magnetic, but cutlery might be slightly magnetic.

Send your message to us

Hot-Dip Galvanized Steel Coil Used for Industry with Very Good Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords