Hot Dip Galvanized Steel Coil Good Quality Zinc Coated Astm A653

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 10000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

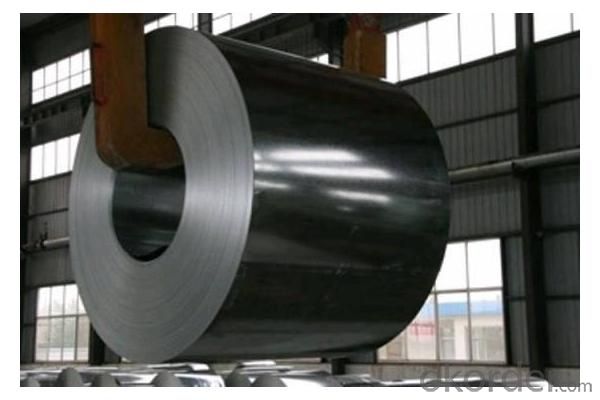

1.Description of Hot Dip Galvanized Steel Coil Good Quality Zinc Coated Astm A653:

The continual hot roll steel coil is made into galvanized steel coil by means of passing through the molten zinc pot. The coating on the product surface is characterized by its uniformity, tightness, erosion resistance and pressure resistance. In addition, the strength of the welding seam is satisfied. The product is widely applied in industries such as construction, home electrical appliance, automotive and machine, etc.

2.Specifications of Hot Dip Galvanized Steel Coil Good Quality Zinc Coated Astm A653:

1).Tolerance for thickness, width, flatness and so on… can conform to the requirements of JIS G3302 or ASTM A653M / A924M.

2).All products with thickness 2.0mm and under can be skin passed.

3).The specification for thicknesses under 1.6mm for hot-rolled base metal according to JIS G3302 will be the same as for thickness 1.6mm and over.

4).Coil inside diameters can be either 508mm or 610mm, maximum coil outside diameter is 2000mm. Weight of a single coil can be from 5 to 30 metric tons.

5).Please contact JOINME STEEL. for Special specifications.

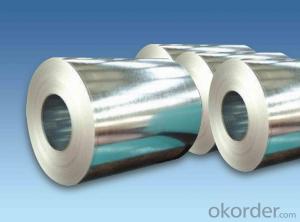

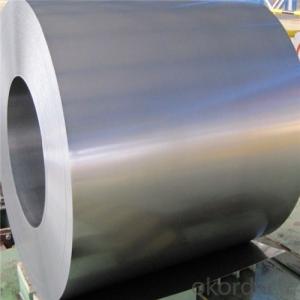

3.Hot Dip Galvanized Steel Coil Good Quality Zinc Coated Astm A653 Images:

4.Hot Dip Galvanized Steel Coil Good Quality Zinc Coated Astm A653 Specification:

Galvanized Steel Coil Feature | (1) Products: GI |

(2) Model: DX51D+Z | |

(3) Certification :ISO 9001, JIS G 3302, EN10327, ASTM A653, GB 2518 | |

(4) Material : Q195, SGCC | |

(5) Thickness : 0.24mm-1.5mm | |

(6) Zinc : Z40-275g (as required) | |

(7) Width : 30-1250mm | |

(8) Coil weight : 2-10 MT(as required) | |

(9) Inner ID : 508mm | |

(10) Application : construction, home appliances, decoration | |

Samples | (1) Hand Sample Time: Within 7-15 days |

(2) Sample Charge: according to product details | |

(3) Sample Refund: negotiable | |

(4) Send Sample: DHL Express. | |

Free sample provided if you need our stock ro check in the quality | |

Packagement | Normal Exporting Packge |

Payment | L/C At Sight OR T/T |

Delivery Time | 30 days after received L/C according to quantity |

Shipping Port | Zhangjiagang / Jiangyin/ Shanghai Port |

(1) We are professional manufcturer of Galvanized Steel Coil. | |

(2) We can assist client to offer integrated product sourcing & production |

5.Our factory:

6.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: What are the different types of steel coil surface treatment options?

- There are several types of steel coil surface treatment options, including galvanizing, painting, chromating, and pickling. Galvanizing involves coating the steel with a layer of zinc to protect it from corrosion. Painting involves applying a layer of paint to enhance the appearance and provide additional protection. Chromating is a chemical process that forms a thin layer of chromate on the surface to improve corrosion resistance. Pickling involves removing impurities and scale from the steel surface using an acid solution.

- Q: How are steel coils processed for different finishes?

- Steel coils are processed for different finishes through various techniques such as hot rolling, cold rolling, pickling, and coating. Hot rolling involves heating the steel coils and passing them through rollers to achieve desired thickness and shape. Cold rolling further enhances the surface finish by reducing thickness and increasing strength. Pickling involves removing impurities and scale from the surface of the steel coils using acid solutions. Finally, coating techniques like galvanization or painting are used to provide protective and decorative finishes to the steel coils.

- Q: Building the bulwurk, general use on trawlers. What kind of steel is best suited.

- How big is your trawler going to be and what use, The ones you see off the Alaska Coast or a Gulf Coast Shrimper? My preference in today's economy would not make sense and that is Aluminum.....not steel at all, maybe even Fiberglass, but $$$$ talk so Steel is cheaper, but you need to know what you are doing. The designer of the hull should have specified the right /preferred grade. It today's world there are many more choices available. You use a mild steel, most often grade A or B, but some applications call for grade D. Check your blue prints and list of materials. Edit. Ok I understand. There are 2 ways to go. One is use a relatively cheep steel and use higher cost epoxy primers and paint, often requiring special surface preparation just before priming, or two, using a much higher cost steel with more chrome and nickel in it. Grades that begin with #3xxx These are weldable with rods that are available, and can be welded directly to mild steels. However these are 3X the cost. If your a Shrimper, I'm guessing gulf coast. I worked with several boat yards in the 70's installing spray urethane foam for insulating there holes. So I've been around lots of small yards from Florida to Texas. I'd call the nearest steel warehouse and ask what they would recommend. You might find what you want at a scrap yard. I've lucked out several times picking up 1/4 plate scrap$ and I'd bet the scrapyard guy would know just what you need. I know there are places to get what you need in Mobile and New Orleans. Good luck!

- Q: How are steel coils used in the manufacturing of agricultural irrigation systems?

- Steel coils are used in the manufacturing of agricultural irrigation systems primarily for the fabrication of pipes and tubing. These coils are formed into the desired shape and size, allowing for efficient water transportation and distribution throughout the agricultural fields.

- Q: If steel can rust with saltwater... then why are ships made of steel? can't we just use other metals like aluminium etc?

- also add to answers above (now below), zincs are mounted on the hull and shaft to draw the electrolysis to them instead of the hull and are easily replaced by a competent diver

- Q: What are the pros and cons of non-stick and stainless steel pots and pans ?Thanks

- My family says I am a great cook, but I can not make a thing in a stainless steel pan. Non stick is the way to go,plus easy clean up is an extra perk.

- Q: What are the challenges in storing and handling steel coils?

- Storing and handling steel coils presents numerous obstacles due to their size, weight, and potential risks associated with transportation and storage. The following are some of the challenges: 1. Space requirements: Steel coils are typically large and bulky, necessitating ample storage space. Finding suitable storage facilities that can accommodate the size and weight of the coils can be difficult, particularly in urban areas with limited space. 2. Weight and handling: Steel coils can weigh several tons, making safe handling a challenge. Specialized equipment, such as cranes or forklifts with sufficient lifting capacity, is necessary to move and position the coils without causing damage or injury. 3. Stackability: Storing steel coils in a secure and efficient manner requires careful consideration of their stackability. Coils must be stacked in a way that prevents deformation or damage to the lower coils, ensuring stability and minimizing the risk of toppling. 4. Corrosion prevention: Steel coils are susceptible to corrosion, especially when exposed to moisture or harsh environmental conditions. Implementing proper corrosion prevention measures, such as protective coatings or climate-controlled storage, is essential to maintain the quality and integrity of the coils. 5. Safety risks: Handling steel coils can be hazardous, as they can unexpectedly shift during transportation or storage. This poses a risk to workers involved in the handling process. Adequate training, appropriate personal protective equipment (PPE), and strict safety protocols are vital to minimize the potential for accidents or injuries. 6. Transportation challenges: Transporting steel coils from manufacturing facilities to storage facilities or end-users can be logistically complex. Coordinating the loading, securing, and unloading of the coils onto trucks or shipping containers requires careful planning and adherence to safety regulations. 7. Quality control: Steel coils must be stored and handled in a manner that maintains their quality. Mishandling or improper storage conditions can result in deformations, scratches, or other defects that can impact the performance and value of the steel. In conclusion, the challenges encountered in the storage and handling of steel coils necessitate attention to detail, appropriate equipment, and adherence to safety protocols to ensure the integrity of the product, the safety of workers, and the efficiency of operations.

- Q: Obviously this is an easy question for anyone who works with metal. However, I am currently writing a book and had an idea that had to do with these two metals. Is it possible for gold to be folded into steel while it is being forged? Do 3-metal alloys exist? If this is not possible with current metal-working techniques and technology, what would be needed to make it possible? And finally, what exactly would the mixing of these two yield? A weak metal? A brittle metal? How would it compare to iron or gunmetal? If you have no idea, please offer speculations. Thank you!

- Since steel is already an alloy (iron with other metals or carbon), you're not alloying gold with a a metal per se. It is possible, though, to alloy gold with steel. However, the creation of any alloy has a practical application behind it. For example, gold is alloyed with silver and copper because otherwise, the gold is too soft to stand up to the use it is intended for and needs to be hardened.

- Q: I wrote in my assignment that mild steel has a high carbon content (4%).This is why it has its strong and rigid properties.. is this correct?

- Steel is defined as an alloy of iron and carbon (often supplemented by further materials) with a carbon content between 0.01 % and 2.06 %. 4% is in the realm of cast iron, which isn't quite as rigid as steel. Mild steel contains 0.16 - 0.29% carbon. You're off by more then a decimal.

- Q: I downloaded broken steel, the notice of my level cap raising was shown, but after reaching the Jefferson Memorial (when you are supposed to activate the purifier) if I kill Colonel Autumn, then Lyons simply says that we must secure the area, and I can't complete the mission. If I let Autumn live, then she gets stuck in a loop saying Steel be with you over and over. Has anyone else experienced this/how can I fix this? I paid $10 for the expansion and I'm getting ripped off.

- Broken Steel alters the ending of the original Fallout 3 to allow continued play after the end of the main quest line. This means that when it is time to go into the reactor at the end of Take it Back!, you can still go in yourself or you can send one of three side characters. However, even if you go yourself, you do not die. Instead, you survive the ordeal and wake up two weeks later at the Citadel. If you allow the Purifier to explode, the game will still end. Elder Lyons will inform you that you and Sarah Lyons were knocked unconscious by an unknown energy spike. Sarah will still be in a coma

Send your message to us

Hot Dip Galvanized Steel Coil Good Quality Zinc Coated Astm A653

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 10000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords