Home Depot Aluminum Coil - Roller Coating Color Coating Aluminum Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Roller Coating Color Coating Aluminum Coil Description:

We can produce aluminum sheet,color aluminum sheet and coil. They are widely used in construction

and decoration, hardware and electric appliances manufacture, automobile manufacture and other

industrial and civil purposes, such as electronic capacitor, rice cooker, refrigerator, computer casting,

lamp shade, air-conditioner, cosmetics cover and box, air-conditioner radiator, inner container of

disinfecting cabinet, ceiling board, automobile motherboard, cover board and top board, etc.

Roller Coating Color Coating Aluminum Coil is free from Oil Stain, Dent, Inclusion, Scratches, Stain

, Oxide Discoloration, Breaks,Corrosion, Roll Marks, Dirt Streaks and other defect which will

interfere with use. Double-faced brushed and painted aluminum has a rough style and clear texture

, Brushed finish with short hairline, Precise color control and uniformity, fade free, resistant to scratch,

never flake or peel, sapphire level rigidity .

2.Main Features of Roller Coating Color Coating Aluminum Coil :

Plain Aluminum Coil

PE Coating Aluminum Coil

PVDF Coating Aluminum Coil

Embossed Aluminum Coil

Aluminum Stripe

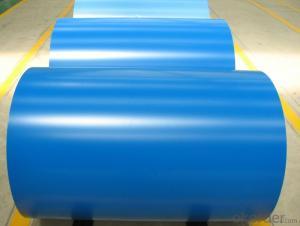

3. Roller Coating Color Coating Aluminum Coil Images:

4. Roller Coating Color Coating Aluminum Coil Specification:

| Alloy No. | Thickness (mm) | Width (mm) | Length (mm) | Temper | |

| A1050,A1060, A1070,A1100 | 0.2-100 | 20-2200 | 20-8000 | O,H12,H22,H14,H16,H18, H24,H26,etc | |

| 3A21,A3003,A3105,A3004 | 0.2-100 | 20-2200 | 20-8000 | O,H14,H18,H24,etc | |

| A5052 ,A5005,A5083,A5754 | 0.2-100 | 20-2200 | 20-8000 | O,H18,H24,H32,H34,H111,H112 ,etc | |

| A6061,A6082,A6063 | 0.2-200 | 20-2200 | 20-8000 | T4,T6, T651,etc | |

| A8011 | 0.2-100 | 20-2200 | 20-8000 | O,H12,H22,H14,H16,H18,H24,H26, etc | |

5.FAQ

Q1.How long have you been in this product?

A1:More than 10 years.

Q2. What's the minium quantity(MOQ)?

A2. 5 Metric tons

Q3. How long is shipping time?

A3. 7 (ready-made products)-25 days(OEM)

Q4. How do you guarantee the quality?

A4. 1. Cooperating and Exchaning experience with sevral quoted aluminum companies

2. Japanese and Swiss production line and skilled works (regular training and testing)

3. more than 10 years production experience.

Q5. Do you have after sale service?

A5. Yes. Any quality problem occurs within one year, pls take photoes,we will be responsible.

- Q: Aluminum metal reacts with hydrochloric acid, HCl, to form hydrogen gas (H2) and a solution of aluminum chloride. Write and balance the equation. Can someone help I just dont get this Al2 + 6HCl → 3H2 + 2AlCl3 Al2 + 2HCl → H2 + 2AlCl 2Al + 6HCl → 3H2 + 2AlCl3 Al + 2HCl → H2 + AlCl2 6Al + 2HCl → H2 + 2Al3Cl

- 2NH4Cl+Ca(OH)2-CaCl+2NH3+2H2O 18 Zn+2Cl-ZnCl2+H2 19 F2+2NaCl-2NaF+Cl2 20 CaO+SO2-CaSO3 21 2CaSO3+O2-2CaSO4 22 2HgO-2Hg+O2 23 CH3OH-CO+2H2 24 2KNO3-2KNO2+O2 you put the question in wrong section. Answer the others by yourself. I have given lots of examples there.

- Q: What will be the pros and cons of using each of these materials?One thing to keep in mind is that aluminum alloys are good conductors of electricity.

- Aluminum is strong and lighter, but not electrically safe. Fiberglass is safe for electrical work and strong, but susceptible to sun damage, and can give out due to cracking. Wood will wear out, and is also damaged by weather, but is safe with electricity.

- Q: Can aluminum coils be used in chemical processing plants?

- Indeed, chemical processing plants can utilize aluminum coils. Aluminum, a versatile and extensively employed substance across multiple industries, including chemical processing, boasts exceptional resistance to corrosion. Consequently, it proves apt for the manipulation and conveyance of diverse chemicals. The application of aluminum coils extends to heat exchangers, condensers, evaporators, and other chemical processing equipment. Moreover, aluminum coils boast a lightweight nature and exhibit high thermal conductivity, promoting efficient heat transfer and energy conservation. Nevertheless, it remains crucial to carefully evaluate the specific demands and compatibility of the chemicals being processed to ascertain the suitability of aluminum coils for the intended use.

- Q: This question asks for methods to determine whether an aluminum coil is safe for use.

- <p>To determine if your aluminum coil is safe to use, first, check for any visible signs of damage such as cracks, corrosion, or deformation. Ensure that the coil meets the required specifications for your application, including thickness, width, and alloy type. Verify the coil's compliance with safety standards and certifications relevant to your industry, such as ASTM or ISO standards. Test the coil's mechanical properties to ensure it has the necessary strength and ductility. Finally, consider the coil's history and usage; it should not have been exposed to extreme temperatures or corrosive environments that could compromise its integrity. Consulting with a materials expert or conducting a thorough inspection can provide further assurance of the coil's safety.</p>

- Q: What precautions should be taken when operating a welding torch on aluminum coils to ensure safety?

- <p>When using a welding torch with aluminum coils, it's crucial to follow safety measures to prevent accidents and ensure a safe working environment. Always wear appropriate personal protective equipment (PPE), including heat-resistant gloves, safety glasses, and a welding helmet. Ensure the work area is well-ventilated to avoid inhaling fumes. Use a backdraft hood or fume extraction system to capture and remove welding fumes. Keep the work area clean and free of flammable materials. Regularly inspect the torch for any damage or wear. Use the correct type of welding rod for aluminum and ensure the gas supply is compatible with aluminum welding. Never leave a lit torch unattended and always follow the manufacturer's guidelines for safe operation.</p>

- Q: This question asks for a comparison between single-coil and multi-coil aluminum tubes, highlighting their differences.

- <p>Single-coil aluminum tubes are made with a single layer of aluminum wound into a cylindrical shape, offering simplicity and ease of manufacturing. They are typically used in applications requiring basic heat exchange or formwork. In contrast, multi-coil aluminum tubes consist of multiple layers of aluminum wound together, which can provide greater strength and durability. They are often utilized in more demanding applications where higher pressure resistance and thermal efficiency are required, such as in high-performance heat exchangers or industrial processes. The multi-coil design also allows for better heat distribution and can handle more stress without deformation.</p>

- Q: wood aluminium windows?

- I would choose vinyl over aluminum, aluminum windows sweat in temp changes. We have installed vinyl windows in two different homes that we have lived in.

- Q: This question asks about the impact of aluminum coils on safety and health protection during welding processes.

- <p>Aluminum coils can significantly affect welding safety and health protection due to their unique properties. Aluminum is lighter than steel and conducts heat quickly, which can lead to faster heat transfer to the welder, increasing the risk of burns. Additionally, aluminum welding produces fumes that contain aluminum oxide, which can be harmful if inhaled over time, potentially causing respiratory issues or even neurological damage. Welders must use proper ventilation and respiratory protection to mitigate these risks. Moreover, aluminum's high reflectivity can cause intense light exposure, necessitating the use of appropriate eye protection to prevent eye injuries. Overall, aluminum welding requires specific safety measures to protect welders' health and safety.</p>

- Q: What are the safety considerations when working with aluminum coils?

- When working with aluminum coils, some safety considerations to take into account include wearing appropriate personal protective equipment such as gloves, safety glasses, and a respiratory mask to protect against any potential hazards. It is also important to handle the coils with care to prevent injuries from sharp edges or heavy lifting. Additionally, ensuring proper ventilation in the workspace and being aware of fire hazards associated with aluminum dust or shavings is crucial.

- Q: Can aluminum coils be used in solar panel systems?

- Solar panel systems can indeed utilize aluminum coils. Aluminum is commonly selected as the material for frames and supports in solar panels because of its favorable combination of lightness and strength. Its resistance to corrosion, durability, and impressive thermal conductivity make it an ideal choice for enduring severe weather conditions and efficiently dispersing heat generated by the panels. Furthermore, aluminum is highly recyclable, which aligns perfectly with the environmentally conscious nature of solar energy systems. In conclusion, incorporating aluminum coils into solar panel systems enhances their efficiency, lifespan, and eco-friendliness.

Send your message to us

Home Depot Aluminum Coil - Roller Coating Color Coating Aluminum Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords