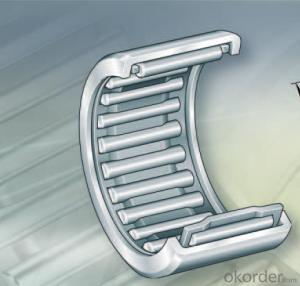

HK 1716 Drawn Cup Needle Roller Bearings HK Series

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 900000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Specifications:

Specification | Model No.: HK 1716 |

Brand Name: OEM | |

Size:17*23*16mm | |

Net weight: 0.016kg | |

Material: Chrome steel | |

Cage: Brass, Steel | |

Features: | 1) Precision: P6 P5 P4 P2 |

2) Noise level: Z1, Z2, Z3, Z4 | |

3) Vibration Level: V1, V2, V3, V4 | |

4) Clearance: C2, C3, C4 | |

5) Hardness: 58-63 HRC | |

6) Greese: As your requirement, such as SRL, PS2, Alvania R12 and so on. | |

Packing | 1.Industrial packing: box |

2.Commercial packing: box then into standard carton/wooden Box | |

3.According customer's requirement | |

Payment | T/T, L/C, Western Union |

Delivery time | About 3 to 5 working days |

Services | Warrantee: 1 year |

Samples: available | |

OEM: available | |

Free technical support and after-sales service |

HK Seal/close type Drawn cup needle roller bearings HK :

1. High accuracy, High speed

2. ISO 9001:2000

3. Can be customized according to your needs

4. Can provide small & miniature standard and non-standard ball berings

5. Reasonable price

6. Technology: low vibration, low noise, high precision and durability

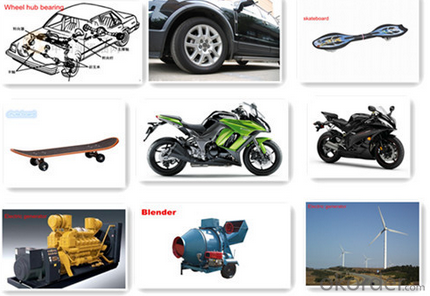

Product Applications:

Needle roller bearings are mainly used in car engines, transmissions, compressors, cranes, etc.

Our Advantages:

1. Excellent and high quality control

2. Prompt delivery

3. Competitive price

4. Small order accepted

5. Customers' drawing or samples accepted

6. OEM service

FAQ:

WHY CHOOSE US ???

1.More than 28 years export experience

2.Strict quality control

3.Delivery in time

4.OEM service are available with good price

5.Low MOQ

- Q: i want which provides us about bearings that means i have seminar on ISO standards--Roller elements bearings

- I have seminar too. So I want that which means seminar ISO standards Journal Bearings, so that makes it OK.

- Q: We have a 1990 Plymouth Voyager and we need to put on new wheel bearings (well my husband says the whole hub)..does anyone know how to go about this?

- heres what you do the 1st step: Get a screwdriver and hammer Step 2: positioned the screwdriver interior the process the bearing and wheel Step 3: positioned yet another wheel below the single you like the bearing is going in Step 4: Pound the real of the screwdriver with the hammer till the bearing is going each of ways in Step 5: Lather, rinse, repeat if nessecary

- Q: And if abec 5 is better. Should I put them in my penny board?

- ABEC is basically meaningless for skates or boards. It is a vibration (higher numbers may roll slower) for high speed machines that are running at speeds that would be around 200 mph on a board. The quality of the maker is more important and some abec 3 bearings may run faster than other abec 5 bearings. The durability of the bearings is also more up to the maker and is not covered by anything in the ABEC standards. Bones is known for making very fast running bearings (they, along with Twin Cam and Zero Drag, make bearings that violate the ABEC standards so they can roll better) but have a reputation that sneezing near them will cause them to rust.

- Q: I want to take care of my bearings and was wondering what the best lubricant for them was

- My favorite is Tri-Flow. Originally used for bike bearings, but works for skateboard bearings as well. Try a bike shop, skate shop or some hardware stores.

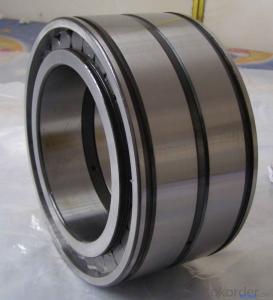

- Q: why combined needle roller bearings for sale is popular in the market? where are they can be used?

- They are particularly suitable for applications where other types of locating bearings occupy too much space, or where the axial loads are too heavy, the speeds are too high, or the lubricant is inadequate for simple thrust washers. So combined needle roller bearings for sale is welcomed. If you are interested in this field, you can get more information from: Changzhou Zhihua Bearings Co., Ltd. It is a professional combined needle roller bearings manufacturer.

- Q: what type of abecs, brand, ect. im tryin to build my own but i would like to know what good parts to put into it before i build it

- thank you for your time have a nice day

- Q: No stupid answers please. Im an ASE master mechanic and I'm looking to hear from experienced off roaders. I'm new to offroading. I'm driving an F250 460 Bigblock 4x4. I know my u joints breaking are normal but am I to expect the same from my tie rods and front manual locking hub wheel bearings once a month if not once a week (I stay up on my alignments). I just bounced my truck three times straight sideways (that's when I really felt the wheel bearings and tie rods go out) so I know I'm very abusive but they are...well were brand new. Is there something I should do as far as suspension or aftermarket parts. I've been doing my homework but any suggestions would help. Rear axle is 30 years old and still kicking major *!*, front end not so much. I do a lot of jumping and climbing. Any suggestions would help. I have an IFS dana 44 front axle. I don't really think of a center pivot axle as IFS and I always thought it looked crappy for offroading. Could it be I need a solid axle?

- no you should not be breaking wheel bearings and tie rods every couple weeks. I have done plenty of off-roading and have never busted a wheel bearing from it. unless you are jumping the truck several feet in the air and turning the steering wheel before it lands. You should not have this problem at all. either you are getting bad parts or they are being installed improperly. And as far as the IFS not being good enough I would not worry about that. The twin I-beam suspension is at least 1 of the best suspensions that you can get for off-roading (especially jumping) EDIT Yes you can beef up the tie rod ends but There is not a way to do the same for the wheel bearings that I know of. Basically if you want to treat the truck like that then you should expect to have to repair it daily. Also if the truck has independent front suspension then it does not have front leaf springs. I would think that a ASE certified mechanic could tell the difference between the 2 but I may be wrong

- Q: i heard people said it makes it stronger. but i dont know if they meant only to put the wheels inside to make the wheels stronger. because i dont want to break my bearings.thankz.

- No. It doesn't do anything to help the wheels. If you insist on trying, take the bearings out. If for some reason you insist on keeping those in there too, make sure you haven't clean them recently or have put lubricant or speed cream in there because it will freeze the bearings and probably create more water than you want in there. I don't recommend it at all, all it will do is make your wheels colder. Also I'm not being mean on the if you insists, just you wont know for yourself if you don't try so if you're like me and need to try something even though it probably wont work, I say that. Again though please don't, because this is one of these things I've tried =P

- Q: So, I guess I need to drop the subframe, crossmember and suspension.I can't get the oil pan out...If you know anything, help!

- Make sure to take the side bolts out of the oil pan. Believe there 12 oil pan bolts 6 side bolts. You can do the rod bearings in the car meaning take the cap off(Do only 1 at a time mark an arrow pointing to the front of the engine if there are no marks on it) But only do one at a time. Rotate the crank so the rod is a straight shot to you, take cap off. Push rod up enough to remove install new bearing. Make sure to put bearings in one way, only fit one way. After installing bearing onto rod, make sure it is flush pull down on the rod itself to seat it in place. Do not use the rod cap the bolts to seat it first. Then once the rod looks like it is in position, then place cap on toque to specs. Then rotate crank if possible to go to next one. Do the next one in line, dont skip around or you may loose track BUT!!!! If you are doing this for the knocking noise at engine start-up, its the piston slap is what is causing that noise it is normal per GM

- Q: I heard using mineral spirits is a good way to clean bearings, but I also heard some can end up damaging them

- The only way i can possibly see mineral spirits damaging a bearing when you clean it, is if you have rubber seals/protectors on the sides of the bearing, and if those are damaged you should replace the bearing. If it's just an open bearing, you can use, brake cleaner, lacquer thinner, diesel, gas or a degreaser to clean your bearings. Just make sure that whatever you use, the bearing is completely dry/free of it, before you repack the bearing, so it doesn't start breaking down the grease you just put in there. I like using brake cleaner and lacquer thinner because it dries fast and doesn't leave any residue.

Send your message to us

HK 1716 Drawn Cup Needle Roller Bearings HK Series

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 900000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords