High Voltage Frequency Drive 10KV 800KW VFD VSD

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Advanced Speed Sensorless Vector Control Algorithm:

Speed sensorless vector control, can have lockedrotorrunning and output 150% rated torque at 0 Hz;

Own patent technology parameter identification method,can have accurate rotation or resting generator parameters

self-learning;Convenient adjustment, easy operation, providing higher control accuracy and response speed;

Apply to winding control, load distribution of multimotor working under the same loads etc.

Rotational speed tracking function

Own patent technology rotational speed tracking algorithm; speediness and smoothness, zero impact tracking generator free rotation speed, only used for MHMD centrifuge, induced draft fan, electromobile etc.

Torque and speed control superior performance

Speed control accuracy can arrive positive and negative 1rpm under 100% torque. Without sensor vector control, torque

response<20ms. With sensor vector control, torque response<5ms.< span="">

Apply to over 10000 turns high speed numerical control main axis.

Decelerate and stop, high performance, 0.1s fast and accurate stopping.

Apply to loads for precision machine tool, synchronized operation, oil pump etc.

Protect Machine’s torque limitation

VTP6 Variable-frequency Drive can provide torque limitation.When torque exceed the maximum torque that machine can

bear, Variable-frequency Drive will limit the torque to its setting maximum torque and protect the equipment's safety

more properly on the premise that the machine develop to the best efficiency.

Reliable torque limitation (torque limitation value 150%),adapt to loads of crane, extruder, etc.

Speediness current-limiting function can avoid Variablefrequency Drive's frequently overcurrent warning. When current exceed current protection point, speediness current-limiting funtion can limit current quickly in current protection point.

In this way, it can protect the equipment's safey and avoid overcurrent warning caused by impact load or other disturbs.

High Starting torque

VTP6 Series AC Drive can provide 150% starting torque at 0.5Hz (sensorless vector control), and 180% zero-speed torque (sensor vector control);

Apply to big starting resistance, fast accelerating and decelerating occasions, and loads for crane, puddling machine, blender, double housing planer, injection molding machine, extruder etc.

1.Output Power:0.75kw-400KW

2.Rated Frequency :50hz

3.Output Frequency Range:0~300Hz(Vector control way)

4.Input Voltage Range:3 phase 380V±15%

5.Output Voltage Range:3 phase 380V±15%

6.Overload Capacity:G Type machine:150% Rotational current 60s;180% Rotational current 3s.

7.Control way: Open loop vector control(SVC) V/F control

8.Starting Torque: G type machine:0.5Hz/150%( SVC)

9.“High precision”, “high performance”, “high cost-effective”.

10.High control precision

11.Rapid torque response

12.High starting torque

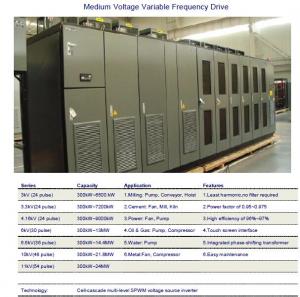

Specification

Model | A03/050~ | A03/100~ | A03/175 ~A03/220 | A03/220~A03/400 | A03/220~A03/610 |

Capacity(kVA) | 250~630 | 630~900 | 900~1150 | 1150~2000 | 2000~3125 |

Rated output current (A) | 50~100 | 100~175 | 175~220 | 220~400 | 400~610 |

Motor power (kW) | 200~400 | 400~710 | 710~900 | 900~1600 | 1600~2500 |

Input frequency | 45Hz~55Hz | ||||

Rted input voltage | 3000V±10% | ||||

Input power factor | 0.95 (>20%load) | ||||

Efficiency | 0.96 with rated load | ||||

Output frequency | 0.5Hz~120Hz | ||||

Frequency resolution | 0.01Hz | ||||

Overload capacity | 120% 1 min, 150% immediately | ||||

Analogue input | 0~10V/4~20mA | ||||

Analogue output | 0~10V/4~20mA | ||||

Acceleration/deceleration time | 0.1~3000s | ||||

Digital output/input | expanded according to requirement | ||||

Ambience temperature | 0~40°C | ||||

Storage/transport temperature | -40~70°C | ||||

Cooling | air cooling | ||||

Ambience humidity | <90% without condensation | ||||

Altitude | <1000 m | ||||

IP class | IP20 | ||||

Size(mm)(W×H×D) | 3300×2480×1200 | 4900×2480×1200 | 6000×2580×1300 | ||

Weight (kg) | 3000 ~5000 | 5000 ~7300 | 7300~9200 | ||

- Q: In the official website to buy ThinkPad notebook, to the power adapter?

- Hello, generally there will be a power adapter with Kazakhstan, unless there is a special note bare metal

- Q: 3.7KW inverter with 2.2KW 6-pole motor running to see the inverter shows the current is more than 4A, with the amount of clamp to 2.8A

- 2, upstairs brothers to answer the correct, the basic frequency is the following constant speed torque control, load changes little, the current change is not large.

- Q: What is the number of parameters of the motor frequency of the Siemens inverter?

- Siemens inverter motor pole number parameter code is r0313 motor pole pairs. Note that the number of pole pairs.

- Q: Can the laptop power adapter be generic?

- Not necessarily, the laptop power adapter has two interfaces for input and output. 1. Input interface is connected to the power outlet, generally divided into two holes and three holes, as well as round mouth and flat mouth of the points; 2. Output interface is connected to the computer side, size, length, diameter, diameter, the pin may have differences, common are: diameter 2.5MM, ordinary mouth, mainstream interface; OD 1.7MM, small mouth; MM, big mouth with a needle, round mouth with a needle and so on. 3. Different voltage, different brands of laptop power adapter voltage is not the same 4. Current is different, different brands of notebook computer power adapter current is not the same In summary, the laptop power adapter between the different types, basically not common

- Q: The inverter is running independently

- . Main working circuit (1) Operation circuit: the external speed, torque and other instructions with the detection circuit current and voltage signal comparison operation, determine the inverter output voltage, frequency. (2) voltage and current detection circuit: isolation with the main circuit potential detection voltage, current and so on. (3) drive circuit: drive the main circuit device circuit. It is isolated from the control circuit to turn on and off the main circuit device. (4) speed detection circuit: mounted on the asynchronous motor shaft speed detector (tg, plg, etc.) signal for the speed signal into the operation loop, according to the command and operation can make the motor running at the command speed. (5) protection circuit: the detection of the main circuit voltage, current, etc., when the overload or over-voltage and other abnormalities, in order to prevent the inverter and asynchronous motor damage

- Q: Delta VFD-F frequency converter how to adjust the number of poles

- Look at the 07 motor parameters, I VFD-F instructions need, then the mailbox sent

- Q: Inverter ACS355 If the speed is outside the allowable range, how to set the limit value

- Remember, 2001 this should be set to a negative number, set to a positive number of your speed will never be less than this value.

- Q: How to view your own laptop power adapter is how much tile?

- 1, the power adapter has a logo, you can find their own look, close to the paper or direct letterpress printed with the voltage, current and power. If there is no write power, the direct voltage multiplied by the current is the maximum power. 2, if the power adapter only identifies the output voltage is 20V, the output current is 4.5A, then we formula W (power) = V (voltage) xI (current) to calculate. Calculate the formula with a power to know the output power is 20 × 4.5 = 90W.

- Q: Do not the laptop directly connected to the power adapter?

- 4, but you can use the external 14 ~ 20V battery, connected to the matching power plug for the notebook power supply, the effect and the use of the same power adapter.

- Q: Speed of 3000 r / min three-phase motor how to change its speed

- The key lies in two points: 1, you ask the variable range is how much? 2, your motor had a few qualifying? If your motor is 6 outlet, and you only need to speed, plus your motor is also an asynchronous motor, and you do not have the requirements of the load; then congratulations, you can achieve "speed" You just put the motor wiring way to do a △ - Y or Y - △ conversion can be achieved. If the above conditions you have one or two can not meet, then your best way is to buy a drive to achieve the variable speed. Of course, you can also make some changes to the winding to achieve the so-called single-winding multi-speed operation (this change, but the need for a certain technical content).

Send your message to us

High Voltage Frequency Drive 10KV 800KW VFD VSD

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches