High Voltage Frequency Drive 10KV 1000KW VFD

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

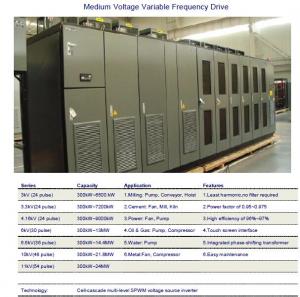

Variable Medium Voltage Frequency Drives Controller

General

Our products are widely used in various industries,such as electricity,water project,mining,oil&gas,chemistry,cement etc.They bring remarkable economic returns for users through optimizing motor control to save energy.

Application

Electricity,Metallurgy,Mining,Petroleum,Chemical engineering,Construction,Paper making, Water project ect.

Abundant Functions

Self-adjusted output voltage,Spinning load operation,Under-voltage ride through,DC breaking,Critical frequency skip,Auto turning,Slip compensation,Precharging,Synchronous transfer.

Specifications

select the product according to the user's technical requirements, applications, economic capability rather than stick features

Our Variable Frequency Drive is widely used for speed regulation, energy saving, soft start and intelligent control for pump, fan and compressor in the industry of thermal power plant, metallurgy, cement manufacturing, mining, chemicals, water supply and sewage disposal etc.

Product Scope:

3KV, 3.3KV Series:-200~1800KVA,mated motor 160KW~1500KW

6KV, 6.6KV Series:-400~5300KVA,mated motor 320KW~4500KW

10KV, 11KV Series:-380~8500KVA,mated motor 300KW~6800KW

Specification

Model | A03/050~ | A03/100~ | A03/175 ~A03/220 | A03/220~A03/400 | A03/220~A03/610 |

Capacity(kVA) | 250~630 | 630~900 | 900~1150 | 1150~2000 | 2000~3125 |

Rated output current (A) | 50~100 | 100~175 | 175~220 | 220~400 | 400~610 |

Motor power (kW) | 200~400 | 400~710 | 710~900 | 900~1600 | 1600~2500 |

Input frequency | 45Hz~55Hz | ||||

Rted input voltage | 3000V±10% | ||||

Input power factor | 0.95 (>20%load) | ||||

Efficiency | 0.96 with rated load | ||||

Output frequency | 0.5Hz~120Hz | ||||

Frequency resolution | 0.01Hz | ||||

Overload capacity | 120% 1 min, 150% immediately | ||||

Analogue input | 0~10V/4~20mA | ||||

Analogue output | 0~10V/4~20mA | ||||

Acceleration/deceleration time | 0.1~3000s | ||||

Digital output/input | expanded according to requirement | ||||

Ambience temperature | 0~40°C | ||||

Storage/transport temperature | -40~70°C | ||||

Cooling | air cooling | ||||

Ambience humidity | <90% without condensation | ||||

Altitude | <1000 m | ||||

IP class | IP20 | ||||

Size(mm)(W×H×D) | 3300×2480×1200 | 4900×2480×1200 | 6000×2580×1300 | ||

Weight (kg) | 3000 ~5000 | 5000 ~7300 | 7300~9200 | ||

- Q: How to choose the right inverter?

- 2, constant torque load Constant torque load equipment requires low frequency inverter torque, dynamic response speed. Inverter 0HZ vector state, to 150% of the torque, to meet the needs of various conditions. For example: a dredger owner bucket inverter system, is a constant torque load, dual motor, and the load overload time is long, so the inverter configuration configuration to enlarge the two models of the G-type machine, while the power supply for the device Machine power supply, the inverter must be configured to input AC reactor.

- Q: Can the laptop's power adapter be used for years?

- Most laptop power adapters can be used for 100 ~ 240V AC (50 / 60Hz). Basically, most of the notebook computers are external power supply, with a power cord and the host connection, which can reduce the size and weight of the host, only a very small number of models built in the host power.

- Q: The relationship between the power supply of the notebook and the battery

- 2, when the laptop turns on the power adapter, and the battery power is low, the charging circuit detects the battery power is lower than the set value, the power adapter will side of the host power supply, while the battery charge. After the charge is restored, it is restored to the power supply state directly from the adapter. Therefore, the relationship between the power supply of the notebook and the battery is that the battery is charged by the power adapter when the battery level is below the set value.

- Q: How is the notebook with a power adapter?

- Clear use: Home use and office with the laptop power adapter to buy a home (AC), the car with the laptop power adapter, to buy a car, you want to use the aircraft on the basis of the car with a The aircraft head on it. Home, car, plane, want to take into account, to buy a two-in-one, or three in one. But if you do not want a few bags of computer weight, you can put a home, put a car, the office put a, so you can not bring to bring, plug to plug, more convenient, you can also give people around

- Q: What is the laptop power adapter? Is it the battery?

- so that the book can be normal operation, or else you think the notebook is 220V Is the voltage at work?

- Q: What is the single axis of the inverter and multi-axis applications

- Inverter is mainly used for AC motor (asynchronous motor or synchronous motor) speed adjustment, is recognized as the AC motor the best and most promising speed control program, in addition to excellent speed performance, the inverter is also significant Energy-saving effect, is the enterprise technological transformation and product upgrading of the ideal speed control device. Since the introduction of China since the 80s of last century, the frequency converter as energy-saving applications and speed of process control more and more important automation equipment, has been rapid development and wide application.

- Q: How to choose the inverter

- I was doing the inverter, you choose the words, as long as 75KW can be selected, huh, huh, because the 1440 speed is fixed, the connection can be set in the inverter itself,

- Q: 11kw 6-pole motor can be used to adjust the inverter to 1800RPM?

- Frequency converter in the 5-50Hz is constant torque frequency, 50-100Hz is constant power frequency, to see what you want to get the effect

- Q: Which machines are used for the frequency converter

- Frequency converter is widely used in the speed regulation of AC motor.Varameter speed control technology is an important development direction of modern power transmission technology, with the development of power electronics technology, AC frequency conversion technology from theory to practice gradually mature. Inverter not only smooth speed, large range, high efficiency, start current is small, smooth operation, and energy saving effect is obvious. Therefore, the exchange frequency control has gradually replaced the traditional traditional slip speed, variable speed control, DC speed control system, more and more widely used in metallurgy, textile, printing and dyeing, smoke machine production lines and buildings, Water supply, air conditioning and other fields.

- Q: Three motors, if coupled with the governor speed, is it necessary to add the inverter?

- ?Fifth, the hydraulic coupler speed: hydraulic coupler is a hydraulic transmission device, generally composed of the pump wheel and turbine, when the pump wheel in the prime mover driven under the rotation, in which the liquid is driven by the blade and rotation, in the Under the action of centrifugal force along the outer ring of the pump wheel into the turbine, in the same turn to the turbine blades to thrust, to drive the production machinery operation. Through different hydraulic (lubricants and turbines) to achieve speed.

Send your message to us

High Voltage Frequency Drive 10KV 1000KW VFD

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords