High Voltage Frequency Drive 3.3KV 1000KW VFD

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

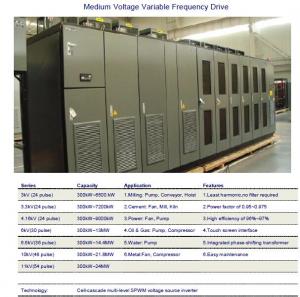

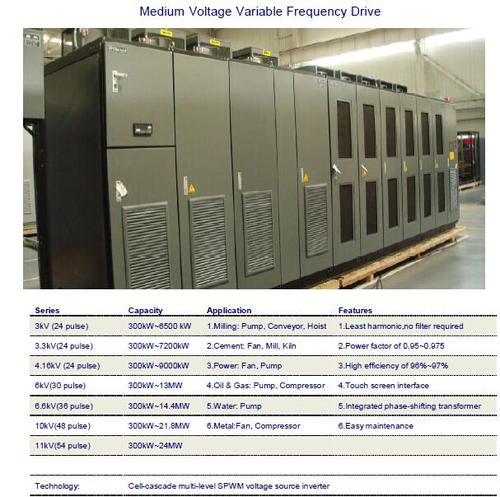

High Voltage 3KV ~11KV AC Driver Inverter

General

CNBM high Voltage Variable Frequency Drives are designed to be highly reliable with high-performance, yet easy to use.It can satisfy users' need for changing the speed of fans or pumps,as well as improve the productivity.

The series are compatible with all types of three-phase medium voltage asynchronous motors.

Advantages :

1. Voltage resource VFD, direct input of 3,3.3,4.16,6,606 and 10 kV,direct output of3,4.16, 6,6.6 and10 kV,no output transformer necessary. High input power factor, low harmonic current, no power factor corrective capacities and harmonic filters required.

2. Sinusoidal multi-level PWM output waveform, no output filter required, can be directly connected to standard induction motor,no harm to the insulation of the cable or the motor, low harmonics of the motor, reduction of vibration of the shafts or the vanes,with the maximal length of the output cable of 1000m.

3. Friendly human-machine interface.

4. Modular design of the power circuits simplifies maintenance routine.

Specification

Model | A03/050~ | A03/100~ | A03/175 ~A03/220 | A03/220~A03/400 | A03/220~A03/610 |

Capacity(kVA) | 250~630 | 630~900 | 900~1150 | 1150~2000 | 2000~3125 |

Rated output current (A) | 50~100 | 100~175 | 175~220 | 220~400 | 400~610 |

Motor power (kW) | 200~400 | 400~710 | 710~900 | 900~1600 | 1600~2500 |

Input frequency | 45Hz~55Hz | ||||

Rted input voltage | 3000V±10% | ||||

Input power factor | 0.95 (>20%load) | ||||

Efficiency | 0.96 with rated load | ||||

Output frequency | 0.5Hz~120Hz | ||||

Frequency resolution | 0.01Hz | ||||

Overload capacity | 120% 1 min, 150% immediately | ||||

Analogue input | 0~10V/4~20mA | ||||

Analogue output | 0~10V/4~20mA | ||||

Acceleration/deceleration time | 0.1~3000s | ||||

Digital output/input | expanded according to requirement | ||||

Ambience temperature | 0~40°C | ||||

Storage/transport temperature | -40~70°C | ||||

Cooling | air cooling | ||||

Ambience humidity | <90% without condensation | ||||

Altitude | <1000 m | ||||

IP class | IP20 | ||||

Size(mm)(W×H×D) | 3300×2480×1200 | 4900×2480×1200 | 6000×2580×1300 | ||

Weight (kg) | 3000 ~5000 | 5000 ~7300 | 7300~9200 | ||

- Q: The inverter control power is also the same, the pole is not the same as the motor 6 or 4 pole can be used?

- Can be used, their rated current is not the same, the need to use the inverter over-current overload protection and other parameters for the corresponding changes.

- Q: In the official website to buy ThinkPad notebook, to the power adapter?

- Tak City gifted, genuine low, 7 days unconditional return. 300 brand-name notebooks for you to choose.

- Q: What parts of the inverter composition

- Simply put, the inverter is mainly composed of rectifier (AC variable DC), filter, inverter (DC variable AC), brake unit, drive unit, detection unit micro-processing unit

- Q: The laptop power adapter is burned

- If the power adapter is burned, you should check the laptop's power outlet, if the socket short circuit will lead to the power adapter burned. Maintenance method is not a power adapter and only use the battery boot try, can not boot, then the laptop itself is a problem, to send maintenance department maintenance; if you can boot, you can confirm that the power outlet is short, can be opened Laptop case, swap a new power outlet to solve the problem.

- Q: Three-phase asynchronous AC motor speed control method

- First, variable pole alignment speed method This method is to change the way to change the stator winding red way to change the cage motor stator pole to achieve the purpose of speed, the characteristics are as follows: With a hard mechanical properties, good stability; No slip loss, high efficiency; Wiring is simple, easy to control, low prices; A level of speed, large difference, can not get smooth speed; Can be used with the regulator speed, electromagnetic slip clutch used to obtain a more efficient smooth speed control characteristics. This method is suitable for production machinery that does not need stepless speed regulation, such as metal cutting machine tools, lifts, lifting equipment, fans, pumps and so on.

- Q: Motor nameplate on the standard 2P, I set the number of motor pole in the inverter, is set 2 or 4 pole?

- 1,2P refers to the number of motor poles, so it is certainly even 2, if the inverter is set to determine the number of motor poles, please write 2P value, if 2P = 4, please write 4 3, look at the nameplate on the motor rated speed for how much, you can confirm the number of motor poles. (N = 60f / p) P: pole pairs

- Q: Does the teacher know the working principle of the inverter?

- Very basic questions, the principle of fine you go online search, everywhere, I do not like to copy someone else, I simply tell you about: Voltage type inverter Three-phase alternating current to the rectifier module, converted into DC, filter stored in the electrolytic capacitor, IGBT + and - from the electrolytic capacitor to take energy, by the DSP (or other controller) output PWM pulse control IGBT turn on and off, So the output AC, the AC and input AC waveform is very different, so that the inverter is also a source of interference. Current filter in the middle of the filter is the inductor non-capacitance, we are more commonly used on the market and the economic converter are mostly voltage-type inverter.

- Q: Abb inverter s510 with water circulation pump why the motor fever. The motor is 2 pole

- Check the inverter operating power factor, straight up the motor to see if it is overheating

- Q: Laptop power adapter how to detect?

- No load voltage, DELL plug more special, the middle needle no load measurement is no voltage, the outer ring outer house and the wall only 19.5V voltage

- Q: Siemens g120 inverter torque limit what is the meaning

- For example, you have 100kg of power, but you can send the power and you lift the weight of the object, if the object weight of 10kg, you can only use 10kg of power.

Send your message to us

High Voltage Frequency Drive 3.3KV 1000KW VFD

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords