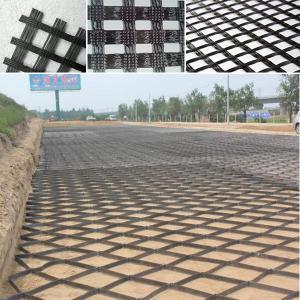

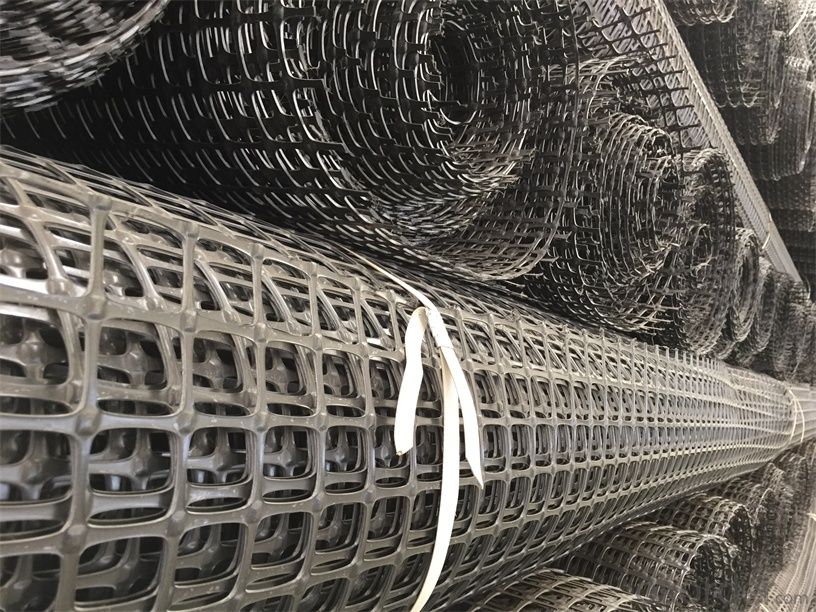

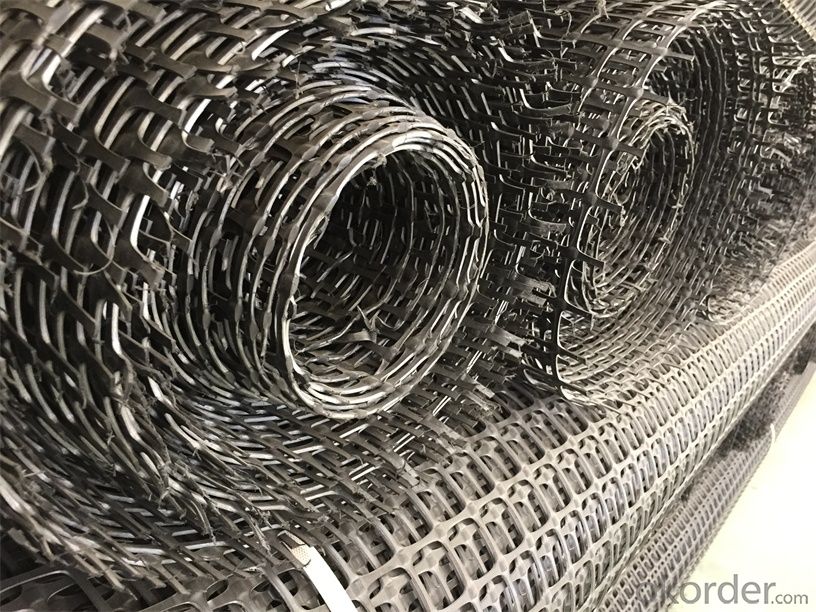

High Tensile Strength Warp Knitted PP Biaxial Geogrid for Soil Stabilisation

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 50000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiberglass Geogrid Introduction:

Fiberglass geogrid is a kind of planar mesh material using alkali-free fiberglass yarn as base body and then coated with high quality modified asphalt. It is warp knitted with oriental structure which gives full play of yarn strength and improves its mechanical property to make the product high tensile, tearing and creep-resistant. Moreover, the composite property of coating with asphalt makes full protection of the fiberglass matrix and greatly improves its wear and shear resistance. All the advantageous functions make the product have a good performance in pavement strengthening, track cracking and solving difficulties of strengthening the bituminous pavement.

Fiberglass Geogrid Features:

1. Light weight, high tensile strength, high modulus, low elongation and good toughness.

2. Corrosion resistance, no long-term creep, long life span.

3. Good physical and chemical stability and good thermal stability.

4. Resistant to fatigue cracking, high-temperature track and low temperature shrinkage cracking.

5. Delaying and decreasing crack reflection.

Specifications | PET20-20 | PET30-30 | PET40-40 | PET50-50 | PET80-80 | PET100-100 | PET120-120 |

Elongation(%) | 10%~15% | ||||||

Vert Tensile strength(KN/m) | 20 | 30 | 40 | 50 | 80 | 100 | 120 |

Horiz Tensile strength(KN/m) | 20 | 30 | 40 | 50 | 80 | 100 | 120 |

Grid(mm) | 12.5×12.5 20×20 24.5×24.5 | ||||||

Width(m) | 1—6 | ||||||

Fiberglass Geogrid Application:

1. Road surface asphalt overlay construction engineering; Asphalt layers

reinforcement.

2. Converting old cement concrete road into composite road; Restraining

reflection cracking caused by block shrinkage.

3. Road extension; Preventing and controlling the cracking caused by new

and old combination and uneven settlement.

4. Treatment of the conjunction between tunnel and bridge or foundation.

Packaging & Shipping:

FAQ:

1. How to order your geogrid ?

a) Tensile strength in warp & weft direction

b) Grid size

c) Roll Width and length

d) Quantity

2. What is the Payment term?

a) TT

b) LC AT SIGHT

c) cash

d) 30% contact value as deposit ,the blance 70% be paid after received the copy of bl .

3. Delivery time

a) 19-25 days after received your depsit .

4. What is MQQ ?

a) 2500 m2 as MQQ , we can also produce sample for you .

Welcome to send your inquiry to us, and if you have any question, we can also help you.

- Q: Can geogrids be used in environmental containment systems?

- Yes, geogrids can be used in environmental containment systems. They are often employed as reinforcement materials in various containment applications such as landfills, ponds, lagoons, and waste storage areas. Geogrids help enhance the stability and integrity of the containment system by providing structural support and preventing soil erosion. They are designed to withstand heavy loads and provide long-term durability, making them suitable for use in environmental containment systems.

- Q: Can geogrids be used in temporary construction access mats?

- Yes, geogrids can be used in temporary construction access mats. Geogrids are commonly used to improve the stability and load-bearing capacity of access mats, making them suitable for temporary construction sites. They help distribute the weight of heavy equipment and vehicles and prevent soil erosion, ensuring safe and efficient access for construction activities.

- Q: Can geogrids be used in temporary retaining structures?

- Yes, geogrids can be used in temporary retaining structures. Geogrids are commonly used to reinforce soil and provide stability in retaining walls and structures. They are versatile and can be used in both permanent and temporary applications, making them suitable for various construction and engineering projects.

- Q: What is the difference between a woven and a non-woven geogrid?

- A woven geogrid is made by weaving synthetic fibers together to create a strong and flexible grid structure. This type of geogrid has high tensile strength and is commonly used for soil stabilization and reinforcement. On the other hand, a non-woven geogrid is made by bonding synthetic fibers together without the use of weaving. It is typically a lower-cost option and is commonly used for filtration and separation applications. Overall, the main difference between the two is the manufacturing process and the intended use.

- Q: How to shop on the road surface of the two

- Each product has a link hole, we also have a professional link accessories. There are circular holes, there are flat holes.

- Q: Are geogrids resistant to extreme temperatures?

- Yes, geogrids are typically designed to be resistant to extreme temperatures. They are made from materials that can withstand a wide range of temperatures, ensuring their performance and durability in various environmental conditions.

- Q: I asked what the raw materials needed for the production were, for example, what the green mesh was made of

- The single belt is formed by the longitudinal and horizontal spacing or the clamping arrangement, and the welding joint is formed by adopting the welding technology of special strengthening bonding to weld the joint. The use of polyethylene production by Seiko weaving. Color usually green or blue.

- Q: What is the significance of each index

- The technical and quality indexes of geosynthetics should meet the design requirements. Storage and laying of GeosyntheticsProlonged exposure or exposure should be avoided during the process. It is strictly forbidden to contain strong acid in the direct contact with geosynthetics,Strongly alkaline substance.

- Q: What are the different types of geogrids available?

- There are several types of geogrids available, including uniaxial geogrids, biaxial geogrids, and triaxial geogrids. Uniaxial geogrids primarily provide strength in one direction, typically used for soil stabilization and reinforcement. Biaxial geogrids offer strength in both directions, commonly used for soil stabilization, retaining walls, and road construction. Triaxial geogrids provide strength in all three directions, ideal for reinforcement in heavy-duty applications like railway tracks and airport runways.

- Q: What is the principle of geogrid?

- Engineering application of steel plastic composite geogrid: can be used for roads, railways, road construction, embankment and abutment, pier, revetment, levees, dams, beach management, freight yard, slag yard, airport, stadium, green building, soft soil foundation reinforcement, retaining wall, slope protection and pavement anti inferior civil engineering. Features: 1, large strength, small creep, adapt to all kinds of soil environment, can fully meet the use of high grade highway retaining wall. 2, can effectively improve the reinforced bearing surface, occlusal function, interlocking greatly improve foundation bearing capacity, effectively restrain the soil lateral displacement of reinforced foundation, stable performance. 3, compared with the traditional grid has greater strength, strong bearing capacity, corrosion resistance, anti-aging, friction coefficient, perforated uniform, convenient construction, long service life and other characteristics. 4, more suitable for deep sea operations, embankment reinforcement, fundamentally solve the other materials to do a long time due to the erosion of the sea cage caused by low strength, poor corrosion resistance, short service life and other technical problems. 5, can effectively avoid the construction process by machine rolling, damage caused by the construction damage. The principle of Anhui geogrid

Send your message to us

High Tensile Strength Warp Knitted PP Biaxial Geogrid for Soil Stabilisation

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 50000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords