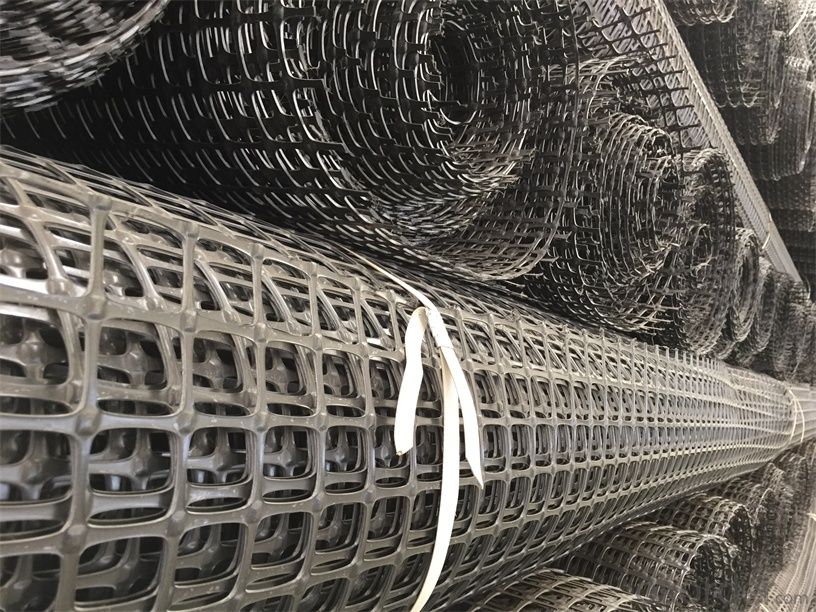

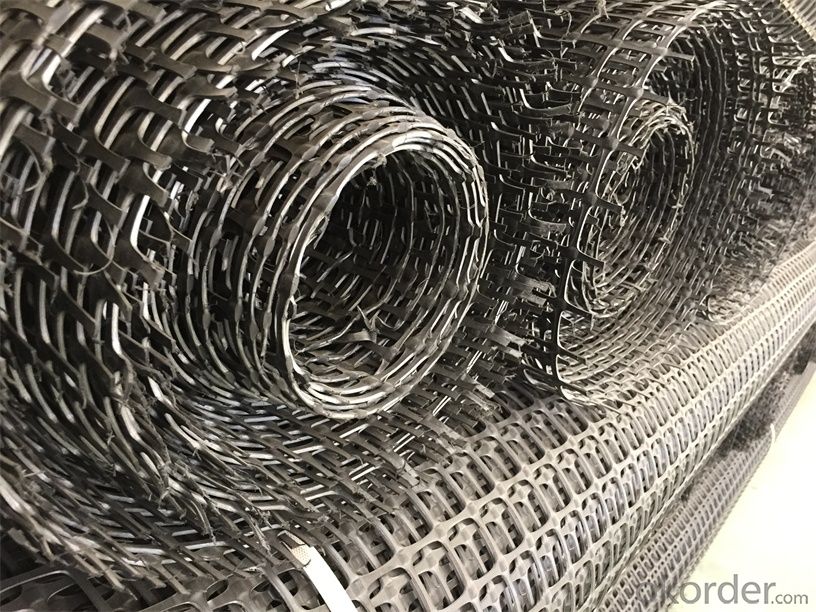

CMAX Velocity Slope Geogrids - High Tensile Strength Warp Knitted PP Geogrids

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 50000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiberglass Geogrid Introduction:

Fiberglass geogrid is a kind of planar mesh material using alkali-free fiberglass yarn as base body and then coated with high quality modified asphalt. It is warp knitted with oriental structure which gives full play of yarn strength and improves its mechanical property to make the product high tensile, tearing and creep-resistant. Moreover, the composite property of coating with asphalt makes full protection of the fiberglass matrix and greatly improves its wear and shear resistance. All the advantageous functions make the product have a good performance in pavement strengthening, track cracking and solving difficulties of strengthening the bituminous pavement.

Fiberglass Geogrid Features:

1. Light weight, high tensile strength, high modulus, low elongation and good toughness.

2. Corrosion resistance, no long-term creep, long life span.

3. Good physical and chemical stability and good thermal stability.

4. Resistant to fatigue cracking, high-temperature track and low temperature shrinkage cracking.

5. Delaying and decreasing crack reflection.

Specifications | PET20-20 | PET30-30 | PET40-40 | PET50-50 | PET80-80 | PET100-100 | PET120-120 |

Elongation(%) | 10%~15% | ||||||

Vert Tensile strength(KN/m) | 20 | 30 | 40 | 50 | 80 | 100 | 120 |

Horiz Tensile strength(KN/m) | 20 | 30 | 40 | 50 | 80 | 100 | 120 |

Grid(mm) | 12.5×12.5 20×20 24.5×24.5 | ||||||

Width(m) | 1—6 | ||||||

Fiberglass Geogrid Application:

1. Road surface asphalt overlay construction engineering; Asphalt layers

reinforcement.

2. Converting old cement concrete road into composite road; Restraining

reflection cracking caused by block shrinkage.

3. Road extension; Preventing and controlling the cracking caused by new

and old combination and uneven settlement.

4. Treatment of the conjunction between tunnel and bridge or foundation.

Packaging & Shipping:

FAQ:

1. How to order your geogrid ?

a) Tensile strength in warp & weft direction

b) Grid size

c) Roll Width and length

d) Quantity

2. What is the Payment term?

a) TT

b) LC AT SIGHT

c) cash

d) 30% contact value as deposit ,the blance 70% be paid after received the copy of bl .

3. Delivery time

a) 19-25 days after received your depsit .

4. What is MQQ ?

a) 2500 m2 as MQQ , we can also produce sample for you .

Welcome to send your inquiry to us, and if you have any question, we can also help you.

- Q: Can geogrids be used in temporary erosion control applications?

- Yes, geogrids can be used in temporary erosion control applications. Geogrids are often employed in these scenarios to stabilize soil and prevent erosion until more permanent erosion control measures can be implemented. They are effective in reinforcing and stabilizing the soil, reducing the likelihood of erosion, and providing temporary erosion control solutions.

- Q: Bi directional plastic geogrid is suitable for engineering

- Wharf cargo yard and other permanent bearing foundation reinforcement.Supply geogrid.

- Q: Geogrid and geotextile, the role is the same?

- Geogrid and geotextile are different

- Q: What are the advantages of using geogrids in ground improvement for seismic stability?

- Geogrids offer several advantages when used in ground improvement for seismic stability. Firstly, they provide reinforcement to the soil, improving its tensile strength and reducing the risk of soil liquefaction during an earthquake. This helps to prevent ground failure and ensures the stability of structures built on the improved ground. Additionally, geogrids can enhance the overall bearing capacity of the soil, allowing it to withstand the dynamic forces exerted during seismic events. Furthermore, these geosynthetic materials are easy to install, cost-effective, and have a long lifespan, making them a practical choice for seismic ground improvement projects.

- Q: What are the design considerations for geogrid-reinforced structures?

- Some design considerations for geogrid-reinforced structures include the selection of appropriate geogrid materials, determining the required strength and stiffness of the geogrid, analyzing the soil conditions and determining the appropriate placement of the geogrid within the structure, considering the compatibility of the geogrid with the surrounding materials, ensuring proper installation and construction techniques, and considering any potential long-term effects such as creep or degradation of the geogrid material.

- Q: Are geogrids effective in reducing soil erosion?

- Yes, geogrids are effective in reducing soil erosion. Geogrids are engineered materials that can be placed in soil to stabilize it and prevent erosion. They provide reinforcement to the soil, increasing its strength and resistance to erosion caused by wind, water, or other factors. By reducing soil erosion, geogrids help to maintain the integrity of slopes, embankments, and other structures, ultimately protecting the environment and promoting sustainable land use.

- Q: Can geogrids be used in temporary construction platforms?

- Yes, geogrids can be used in temporary construction platforms. Geogrids provide structural reinforcement and stabilization to the soil, making them suitable for supporting heavy loads and providing a stable working surface during temporary construction projects.

- Q: Are geogrids resistant to biodegradation?

- Yes, geogrids are typically resistant to biodegradation. Geogrids are made from synthetic materials such as polyester or polypropylene, which are designed to be durable and resistant to decay caused by biological organisms or environmental factors. This resistance to biodegradation makes geogrids suitable for long-term applications in civil engineering, soil stabilization, and erosion control.

- Q: Are geogrids suitable for reinforcing landfill liners?

- Yes, geogrids are suitable for reinforcing landfill liners. Geogrids are commonly used in landfill construction to enhance the stability and strength of liners, preventing soil erosion and improving overall performance. They provide additional reinforcement to the liner system, enhancing its durability and longevity. Geogrids also help to distribute loads and reduce settlement, ensuring the integrity of the landfill liner.

- Q: Can geogrids be used in reinforcement of bridge approach embankments over soft soils?

- Yes, geogrids can be used in the reinforcement of bridge approach embankments over soft soils. Geogrids are commonly employed in such applications to enhance the stability and strength of the embankment by distributing the loads and reducing settlement. They provide additional tensile strength and improve the overall performance of the embankment, making it a suitable solution for addressing the challenges posed by soft soils in bridge approach embankments.

Send your message to us

CMAX Velocity Slope Geogrids - High Tensile Strength Warp Knitted PP Geogrids

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 50000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords