High Tensile Strength Fiberglass Rail Track Reinforcement Geogrids with CE Certificate for Road Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 g/m²

- Supply Capability:

- 600000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

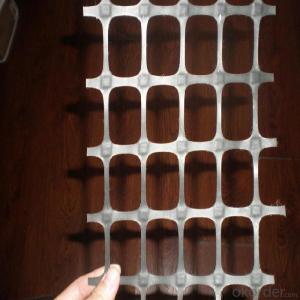

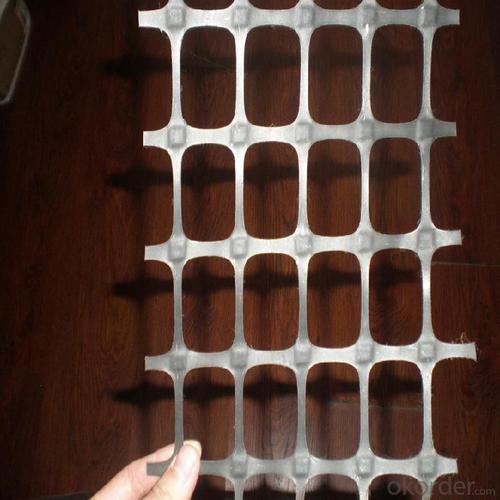

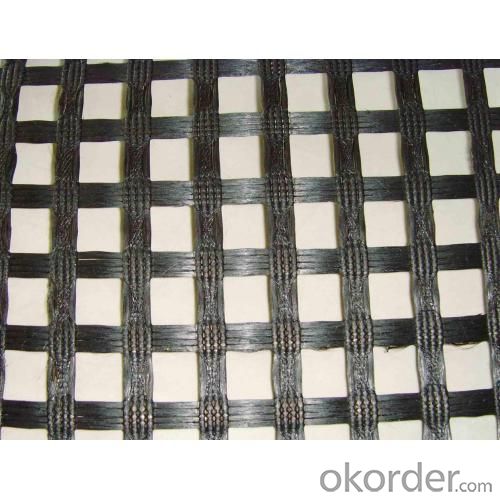

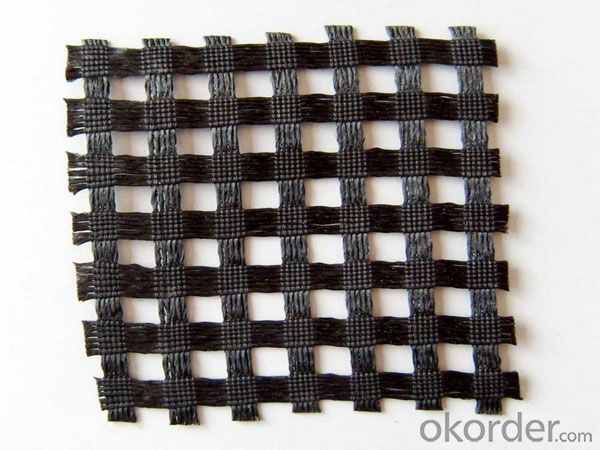

Structure of High Tensile Strength Fiberglass Geogrid Description:

High Tensile Strength Fiberglass Geogrid is a kind of reinforcement product, Both warp and weft directions are high tensile strength and low elongation. It can be used in the construction o railway, highway, bridge, wharf, etc., which require firm-quality construction materials for security purpose. Therefore basalt fiber geogrid is an ideal material for construction.

Main Features of High Tensile Strength Fiberglass Geogrid:

High strength, high modulus and low elongation.

Aging resistance and high tensile strength.

Pre-designed and easily combing with gravel and soil

Could replace steel-plastic geogrid in coal mine.

High Tensile Strength Fiberglass Geogrid Images

High Tensile Strength Fiberglass Geogrid Specification:

Index Properties | Units | MD Values | XMD Values |

Aperture Dimensions | mm(in) | 25(1.0) | 33(1.3) |

Minimun Rib Thickness | mm(in) | 1.27(0.05) | 1.27(0.05) |

Tensile Strength @2% Strain | KN/m(lb/ft) | 6.0(410) | 9.0(620) |

Tensile Strength @5% Strain | KN/m(lb/ft) | 11.8(810) | 19.6(1,340) |

Ultimate Tensile Strength | KN/m(lb/ft) | 19.2(1,310) | 28.8(1,970) |

Junction Efficiency | % | 93 | |

Flexural Stiffness | Mg-cm | 750,000 | |

Aperture Stability | m-N/deg | 0.65 | |

Resistance to Installation Damage | %SC/%SW/%GP | 95/93/90 | |

Resistance to Long Term Degradation | % | 100 | |

Resistance to UV Degradation | % | 100 |

FAQ

We have organized several common questions for our clients,may help you sincerely:

Q1: How about your company?

A1:Our company are one of the largest geosynthetic products supplier in the world.We have the products experience more than 20 years.Already export to USA/Germeny/Australia/Zambia/Brazil etc.more than 20 countries.Almost 10years.Our products including Geocell/Fiberglass Geogrid/Geomembrane/Geotextile/Geonet etc.

Q2.Does your products have good qualitity?

A2:Yes,we have do many big projects such as the 2008 Beijing Olympic BIRD NEST. Divert water from the south to the north project. And our products have CE certificate also.

Q3:How long can we receive the products after purchase?

A3:In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 15-20 working days can be delivery.

- Q: Are geogrids resistant to UV radiation?

- Yes, geogrids are typically designed to be resistant to UV radiation.

- Q: How do geogrids help in reducing the risk of soil compaction?

- Geogrids help in reducing the risk of soil compaction by providing reinforcement and stability to the soil structure. They distribute the load evenly and prevent excessive pressure on the soil, thus reducing the chances of compaction. Additionally, geogrids improve the soil's strength and prevent it from settling, which further helps in minimizing the risk of compaction.

- Q: Can geogrids be used in temporary retaining walls?

- Yes, geogrids can be used in temporary retaining walls. Geogrids are commonly used in various types of retaining walls, including temporary ones, to enhance stability and improve the overall strength of the structure. They provide reinforcement to the soil, reducing the risk of wall failure and ensuring the integrity of the retaining wall during its temporary use.

- Q: How do geogrids help with slope stabilization?

- Geogrids help with slope stabilization by providing reinforcement and increasing the stability of soil or rock slopes. They are placed within the slope to distribute the forces acting on it and prevent slope failure. The geogrids act as a barrier, reducing erosion and soil movement, while also enhancing the overall strength and load-bearing capacity of the slope.

- Q: What are the types of geogrid, respectively, what role?

- Glass fiber geogrid features:The product has the characteristics of high strength, low elongation, high temperature resistance, high modulus, light weight, good toughness, corrosion resistance, long service life, can be widely used in the old cement pavement and airport runway maintenance, dams, river, slope protection, bridge pavement engineering field enhancement processing, can give the pavement reinforcement and reinforcement to prevent rutting, fatigue crack of pavement, hot and cold crack and the expansion of reflection crack, and can disperse the bearing capacity of pavement and prolong the service life of the pavement, high tensile strength and low elongation, no long-term creep, high physical and chemical stability, thermal stability, fatigue cracking, rutting resistance, cracking resistance at low temperature delay, reduce the reflection crack.

- Q: Are geogrids suitable for use in soil reinforcement for bridge abutments?

- Yes, geogrids are suitable for use in soil reinforcement for bridge abutments. Geogrids offer a cost-effective solution to improve the strength and stability of soil, preventing erosion and settlement. They provide excellent tensile strength and interlocking capabilities to distribute loads, making them effective in reinforcing bridge abutments and enhancing their performance.

- Q: What are the names of geotextiles?

- ASTM 4439 standards in the definition of geotextiles are: a purely permeable geosynthetics composition of textiles. Materials used in soil, rock, soil, or other geotechnical engineering, and as part of a human - made project.

- Q: How to determine the number of geogrid detection method

- In the finished product cut at least 1 meters of the length of the geogrid, the radial shear of the 3, the zonal shear of the 3, and then tested, take its average value can be.

- Q: What are the long-term durability characteristics of geogrids?

- Geogrids have excellent long-term durability characteristics. They are typically made from high-strength materials such as polyester or polypropylene, which are resistant to degradation caused by UV exposure, chemical exposure, and biological factors. Geogrids also have high tensile strength, allowing them to withstand heavy loads and maintain their structural integrity over time. Additionally, they have low creep and deformation rates, meaning they can maintain their original shape and performance for an extended period. Overall, geogrids have proven to be highly durable and reliable for various applications in civil engineering and construction.

- Q: Geotextiles and geogrids to do the re inspection approach?

- In theory it is necessary

Send your message to us

High Tensile Strength Fiberglass Rail Track Reinforcement Geogrids with CE Certificate for Road Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 g/m²

- Supply Capability:

- 600000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords