High Tensile Strength Extruded Geogrids Geotextile Bags for Sale

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Products Description

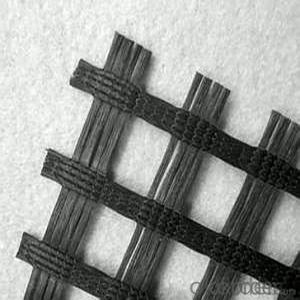

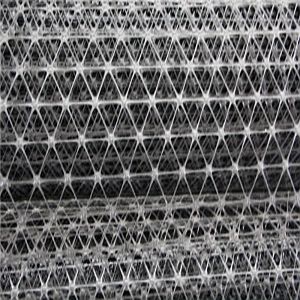

Extruded Geogrids are flat structures in polymer (usually high density polyethylene or polypropylene) that are extruded and then pulled: this may be done in one direction (mono-oriented geogrids), or in the two main directions (bi-oriented geogrids). They are used in soil and road paving reinforcement.

Bonded Geogrids are flat structures, where two or more series of strip elements made of polyester coated with polyethylene, are linked at regular intervals by means of bonding.

Woven Geogrids are flat structures in the shape of a net made of high module synthetic fibres, that may also be coated with a further protection layer, using synthetic material (usually PVC or other polymer).

Application

1. Roadbed reinforcement in highway, railway and municipal road, prevent road surface crack

2. Reinforcement and separation in dam and river, improve soft soil bearing capacity and stability.

fiberglass geogrid/glass fiber geogrid with CE certificate Introduction: Fiberglass geogrid is a kind of new favorable earthwork base material to strengthen the road surface and roadbed. This product is composed of fiberglass filaments that are coated with an inorganic sizing agent

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: Geotextile price, the number of square feet per square

- You have different specifications and different prices. The number of square feet per ton to see how much you do grams, the greater the weight, the less the square number. Huazhi geotextile material manufacturers to answer.

- Q: Are geotextiles resistant to UV radiation?

- Yes, geotextiles are generally resistant to UV radiation.

- Q: What is the difference between a hard pipe and a mesh plastic blind ditch?

- Different products, all play the role of drainage ditch need to wrap geotextered soft water pipe does not require geotextile package. Huazhi geotextile material answer

- Q: What are the environmental impacts of geotextile production?

- The environmental impacts of geotextile production primarily include energy consumption, greenhouse gas emissions, and waste generation. The production process requires significant amounts of energy, mainly derived from fossil fuels, leading to carbon dioxide emissions and contributing to climate change. Additionally, the extraction and processing of raw materials for geotextiles can result in habitat destruction and soil degradation. Furthermore, the production process generates waste, such as wastewater, air emissions, and solid waste, which can have adverse effects on local ecosystems if not properly managed.

- Q: Are geotextiles suitable for use in geotextile tube dewatering systems?

- Yes, geotextiles are suitable for use in geotextile tube dewatering systems. Geotextiles are commonly used in these systems to provide filtration and separation of water from solids. They allow water to pass through while retaining the solids, making them an effective solution for dewatering and sediment containment projects.

- Q: Geotextile price geotextile how much money a square meter

- Geotextile is a new type of building materials, raw materials are polyester, polypropylene, acrylic, nylon and other polymer polymer synthetic fiber. In accordance with the manufacturing method is divided into: there are two types of geotextile and non-woven geotextile. According to the use of anti-seepage, anti-filter, drainage, isolation, reinforcement, protection, sealing and so on a variety of functions, based on a variety of factors, the price is not the same, we would rather discuss with the price, Hongxiang new materials company Meng Xiangyu that sell products is not just look at profits, if only the simple pursuit of profit level, it is too easy, but if you want to assume the responsibility of the consumer, the quality of the project Responsibility, but need to spend a lot of effort. To this end, we do not count the cost, put a lot of manpower and resources to innovation, to transform, choose the best materials and the best modern equipment, put a lot of manpower, material resources to innovation, to create brand value, Can create the greatest green benefits. High-end quality and green is a commitment, we promise not to short-term interests, betray the future!

- Q: Can geotextiles be used in bridge abutment reinforcement?

- Yes, geotextiles can be used in bridge abutment reinforcement. Geotextiles are commonly employed in civil engineering projects, including bridge construction, to improve soil stability and provide erosion control. When used in bridge abutment reinforcement, geotextiles can help distribute loads, prevent soil erosion, and increase the overall stability and longevity of the structure.

- Q: How are geotextiles used in shoreline protection?

- Geotextiles are used in shoreline protection as a barrier against erosion. They are placed along the shoreline to prevent the loss of sediment and stabilize the soil. The geotextiles act as a filter, allowing water to pass through while retaining the soil particles. This helps to reduce wave impact, control water flow, and protect the shoreline from erosion caused by natural forces.

- Q: How do geotextiles help with moisture management in construction projects?

- Geotextiles help with moisture management in construction projects by acting as a barrier that allows water to pass through while preventing soil erosion. They can be used to separate different layers of soil or aggregates, preventing the mixing of fine and coarse materials and ensuring proper drainage. Additionally, geotextiles can help control groundwater by providing filtration and reducing the risk of water accumulation, ultimately enhancing the overall stability and durability of construction projects.

Send your message to us

High Tensile Strength Extruded Geogrids Geotextile Bags for Sale

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords