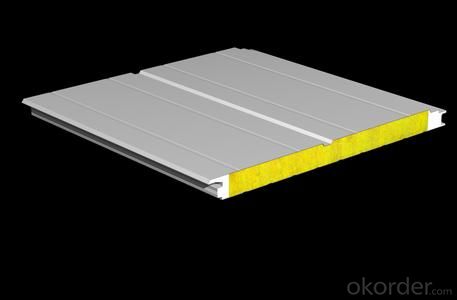

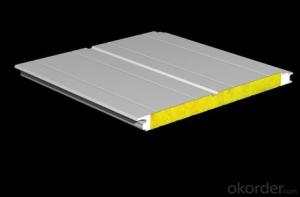

Coolroom Sandwich Panels - High Strength with Tight Connection PU Sandwich Panel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

High strength with tight connection pu sandwich panel

1. The advantages of PU sandwich panel:

1) Advanced equipment makes excellent products: Our factory chooses the world's most advanced Italy's third generation equipment, the whole equipment costs more than 8,000,000USD. It is fully controlled by computer robot, without any manual operation.

2) U.S. imported raw material: All raw materials are imported from the United States, global brand ranks No.1, with 100% zero defect, in order to make our customers feel relieved.

2. Main features of PU sandwich panel:

1) Good chemical resistance, waterproof & fire resistant,anti-corrosion, etc.

2) The colored steel sandwich panel usually use parallel clasp to install on site. It has the advantages of being easy to install, time efficient, material efficient, even more, high in strength, etc. It is especially applicable to suspended ceiling and partition systems, Installation is convenient and flexible without the large-size lifting devices so that the construction period is limited with the lower comprehensive costs.

3) The PU panels we offer are also used in making of the containers which are used mostly for the storing of the food items including Poultry, Fruits, vegetables etc.

3.Specifications of PU sandwich panel:

Steel Thickness | 0.3~0.6mm |

Panel thickness | 50/75/100/125/150/200 mm |

Effective width | (1) 950/mm ---for roof (2) 950/1150mm---for wall or ceiling |

Length | According to customer's request,less than 11.8m |

Materials | Inner is PU/Rockwool, two sides is Color steel tile |

Structure | three layers: (1)upper layer is steel sheet, (2)the inner layer is PU sandwich, (3)the bottom layer is also steel sheet |

Rockwool density | 30-50(kg/m³),etc |

color | blue,white grey or other colors . |

Parts | Steel line for easy connect one by one Film covering in order to protect the steel of panels |

Lifetime | 15~20 years |

Character | Light in weight, heat insulation, fireproof and waterproof,environmental |

Usage | various roofs and walls referring to the large size factory buildings,storages, exhibition halls, gymnasiums ,etc |

Packing | Packed by shipping Container or according to your demands |

4. Characters of PU sandwich panel:

•Heat insulation

•Durable-more than 30 years

•Good quality- ISO 9001:2000

•Waterproof and fireproof

•Light weight

•Cost-saving-the lowest price of sandwich panel

•Environment protection- highly recommend by the government

•Large span and most area saving

5. Application of PU sandwich panel:

Steel house, suburban housing, villa, kindergarten, model house for apartment, commercial building, remodeling of old structures, warehouse, steel structure house, workshop, work plant, airport, cold storage, mobile house, etc.

- Q: I have a temporary pavement, the roof for the Caigang sandwich panels, north and west for the pure glass wall, south of four large area of plastic windows, east brick wall, an area of 150 square feet, 5 meters high. Summer sun good time when the house hot, temperature 35 degrees or more. Ask how the decoration, so that the temperature can come down, the cheaper the better the cost. (The ceiling has no effect, the role of large or small, there is no other way) Thank you, high score waiting. More

- (Including: Fluorocarbon metal paint, fluorocarbon solid paint, real stone paint, imitation stone paint, granite, relief supporting, imitation brick texture, texture matching, etc) and insulation materials series (including: XPS , EPS, PUR, phenolic board, rock wool board, ultra-thin insulation board), for the old and new concrete, steel structure, real brick wall, hollow brick wall, brick wall wall, combined with the company to install patent, Construction of the wall installation TDD insulation decorative board is not only suitable for the new building exterior insulation and decoration, but also for the old building of low-carbon energy-saving decorative transformation, and not affected by regional differences

- Q: Air conditioning year after the addition of Calvary is not the reason for refrigeration

- It is said that the earth will produce a carcinogenic material, in the sixth floor above will not have an impact on people, you are not taking into account the life on the moon ah

- Q: Will the Yanmian sandwich panels do external wall insulation wall can paste tiles? Do A-class insulation of the external wall insulation materials can be posted what kind of it?

- Single row of scaffolding, that is, the entire frame by a row of pole composition; due to its small range (generally only used in decorative construction), poor stability, erection height is small, has gradually withdrawn from the construction market

- Q: Polyurethane sandwich panels in the polyurethane is what material, what are the benefits of industrial building materials should choose polyurethane?

- Extrusion board is different from the foam board, bulk density can not be arbitrarily changed, the technical units to do relatively light But not less than 30kg / cubic meter is generally 35kg / m3 or so manufacturers and manufacturers different

- Q: General color steel foam sandwich panels. How much a square is flat

- Plywood is made of three or more layers of 1mm thick veneer sheet made of hot pressing Plywood is generally divided into 3mm, 5mm, 9mm, 12mm, plywood buy plywood by multi-layer single The plates are arranged in a crisscross arrangement The outermost front panel is called a panel, and the back is called a backplane The inner board is called the core plate Ask the question? The They said that the use of the shoe cabinet, wardrobe with a sandwich panel answer:

- Q: What is the weight per unit area of 100 thick rock wool sandwich panels?

- The development of safe electricity technical measures and electrical fire prevention measures. ⒋ construction site temporary electricity safety technology files: ⑴ temporary electricity construction organization design and modify the construction organization design all the information. ⑵ technology to the end of information. ⑶ temporary electricity inspection inspection table. ⑷ grounding resistance measurement records. regular inspection (complex) look-up table (site monthly, the company once a quarter). ⑹ earthen worship of the cut of the irrigation pipe tax japonica maintenance work records. ⒌ installation, repair or removal of temporary electricity projects, must be completed by the electrician, electrical grade should be consistent with the degree of engineering and technical complexity to adapt. Second, the electrician: ⒈ electricians must go through professional and safety technical training, by the (city) labor department examination issued a certificate of operation, the prospective independent operation. ⒉ electrician should grasp the basic knowledge of electricity safety and all equipment performance. ⒊ before the job as required to wear personal protective equipment. slightly....

- Q: Can sandwich panels be used for noise barriers?

- Yes, sandwich panels can be used for noise barriers. Sandwich panels are typically made of two outer layers of rigid materials, such as metal or wood, with a layer of insulating material in between. This insulating layer helps to absorb and dampen sound waves, making sandwich panels an effective choice for noise barriers. The insulating material in sandwich panels can be made of various materials, such as mineral wool or polyurethane foam, which have excellent sound absorption properties. These materials are designed to trap and dissipate sound energy, preventing it from passing through the barrier and reducing the noise levels on the other side. Sandwich panels for noise barriers can be customized to meet specific noise reduction requirements. Different thicknesses and densities of the insulating layer can be used to achieve the desired level of sound insulation. Additionally, the outer layers can be designed to be reflective or absorptive, depending on the desired acoustic performance and aesthetic preferences. Sandwich panels offer several advantages for noise barrier applications. They are lightweight, making them easy to install and transport. They also have a high strength-to-weight ratio, providing structural integrity to withstand environmental factors such as wind and vibrations. Furthermore, sandwich panels can be designed to be durable and resistant to corrosion, ensuring long-lasting performance in outdoor environments. In conclusion, sandwich panels are a suitable choice for noise barriers due to their sound absorption properties, customization options, and durability. They can effectively reduce noise levels and provide a quieter environment for various applications, such as highways, factories, residential areas, and commercial buildings.

- Q: The general company to re-change the new version, the replacement is very troublesome. Our company's exterior wall decoration board convenient installation, thermal insulation, waterproof moisture, noise reduction noise are interested can consult. Polyurethane sandwich panels for the application of polyurethane sandwich panels

- . different fire rating: Yanmian sandwich panels for the A-level, EPS for the B3-class, polyurethane B1 level. . different insulation properties: the three polyurethane sandwich panels the best. . waterproof performance is different: the three polyurethane and EPS better than rock wool. . the density of different: rock wool bulk density is generally 120KG / cubic meter, EPS is generally . polyurethane is generally 40. In short, the overall performance of polyurethane sandwich panels for the best, is the best choice for steel structure, Have a number.

- Q: Sandwich board is the two sides are metal, the middle of the building materials is the problem of foam added: What is the use of more adhesive

- According to material classification: can be divided into inorganic insulation materials, organic insulation materials and composite insulation materials three types. Inorganic insulation materials are common: YT inorganic reactive wall insulation materials, rock wool board, glass beads insulation mortar, foam cement board, glass wool board and so on. Organic insulation materials are: molded polystyrene board, extruded polystyrene board, phenolic resin board, polyurethane plate and so on. According to the shape classification: can also be divided into plate, powder and so on. According to the fire rating: divided into A-class non-flammable type, B1 grade flame retardant, B2 grade combustible type. Inorganic insulation materials are A-class materials, organic insulation materials up to B1 level.

- Q: Consult the requirements of the flame retardant 0 standard from which the standard standard, and then ask the next level 0 flame retardant standard self-extinguishing time is how much. More

- Clamp material, and pressure ah, a little bit of deformation of the clamp will lead to the next time the use of water leakage; some clamp is sealed with rubber ring, pressure, the rubber ring is not fully restored, will lead to Leakage of water; some cases in the pressure, the pipeline to the development of the process of training, but also lead to tight hoop tightly

Send your message to us

Coolroom Sandwich Panels - High Strength with Tight Connection PU Sandwich Panel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords