High Silica Ceramic Fiberglass Casting Filter Plate

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

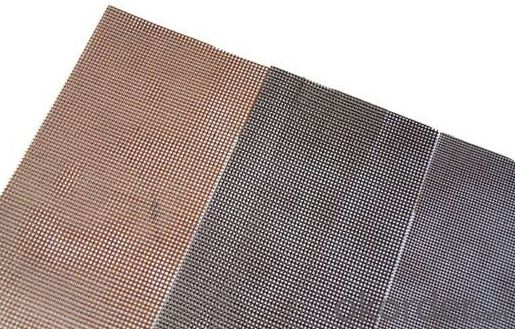

High silica fiberglass casting filter

high silica mesh casting filter can effectively remove slag,refractory particles and non-metallic inclusions from molten metals.It is developed as a low cost but with rather filtration efficiency

alternative to ceramic filters.Made from specially treated silica yarns,silica mesh filters are capable of

withstanding pouring temperatures up to 1620 Degree C.Silica mesh filters are ideal for in-mold filtration of gray, malleable,white,compacted graphite and ductile cast irons, as well as non-ferrous

aluminum and copper-based metal alloys and many types of small scale steel casting filtration.

ADVANTAGES:

• Low cost and easy to use

• Improves fluidity and metal distribution

• Removes micron sized inclusions and impurities

• Can be used with existing pattern equipment

• Eliminates inclusions created by ceramic chips

APPLICATIONS:

• Cut pieces for in mold filtration like sand casting,gravity casting,etc.

• Cut pieces for riser sleeves,bottom or across ports in walls

• Cut pieces to provide a weakened plane for riser knock-off

• Cup shapes for investment casting

SPECIFICATION:

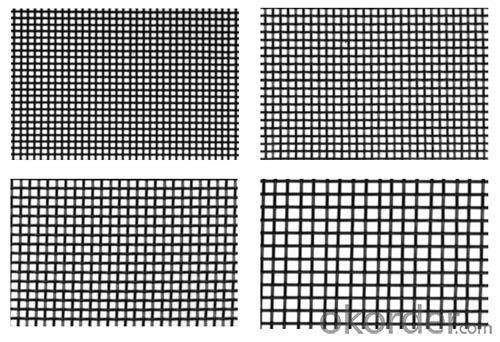

Model No. | SiO2% | Thickness | Mesh size | Max.Temp. | Open area | Max.work time |

HSFG-15 | ≥96 | 0.35mm | 1.5x1.5mm | 1450℃ | 55% | 10minutes |

HSFG-20 | ≥96 | 0.35mm | 2.0x2.0mm | 1450℃ | 60% | 10minutes |

HSFG-25 | ≥96 | 0.35mm | 2.5x2.5mm | 1450℃ | 70% | 10minutes |

HSFG-S15 | ≥96 | 0.98mm | 1.5x1.5mm | 1620℃ | 22% | 15seconds |

HSFG-S20 | ≥96 | 0.98mm | 2.0x2.0mm | 1620℃ | 26% | 15seconds |

HSFG-S25 | ≥96 | 0.98mm | 2.5x2.5mm | 1620℃ | 32% | 15seconds |

FILTERING TIPS:

• Copper alloys&leaded bronze:1.5x1.5mm mesh

• Gray Iron:1.5x1.5mm mesh

• Ductile Iron:2.0x2.0mm &2.5x2.5mm mesh

• Small scale steel:1.5x1.5mm mesh

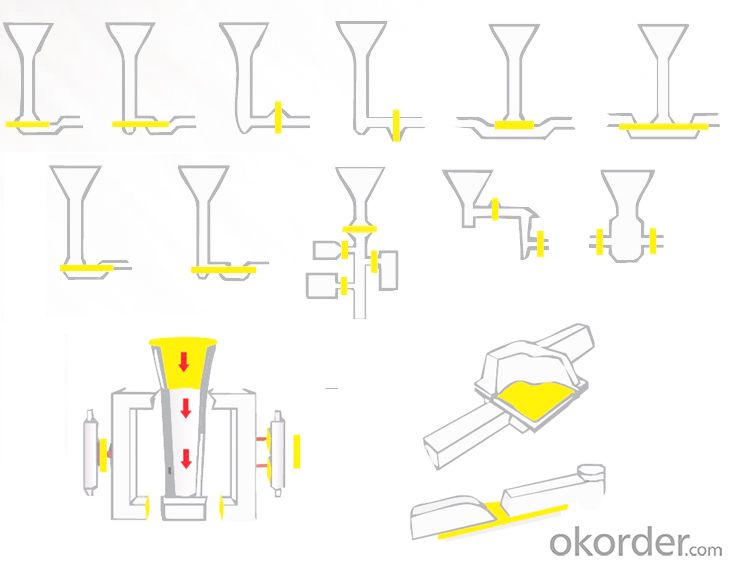

PLACEMENT POSITION:

*Cut pieces can be rectangular or round,size from 20mm to 900mm.

*Preformed cup filter OD can be 100/110/115/120mm or as per request.

- Q: The ceramic filter suddenly did not smoke, and later he was all right. What's the reason?

- How old the general ceramic filter suction main reason mud cake thickness is not much of a ceramic filter plate is different, because the ceramic filter backwash water, vacuum suction and nitrate are through the distribution valve, are often the same boat". See your description, you do not know the 5 line is about "5 disc or sideways 5 rows of ceramic plates, that is completely not suction or suction effect is poor, I hope to help you:

- Q: The ceramic filter plate is broken. What will happen to the vacuum pump?

- That's a good question. I hope my answer will help you.Ceramic filter ceramic plate broken, nothing more than ceramic plate plug and ceramic plate rupture, you should be the problem of ceramic plate rupture.

- Q: What happens when the pressure on the filter plate is uneven during backwashing?

- The working process of ceramic filter is: suction - drying - unloading - backwash - suction - drying - unloading - backwash...... In circulation, suction, the drying process is to make the slurry liquid by vacuum suction and capillary effect (usually water) through the filter media from the left, the filter cake on the filter medium (the two processes like device, through the pump) scraper discharge, discharge will complete a ceramic filter in the absorption cycle, slurry, drying process, some fine particles may enter the filter medium or stacked on the surface (a lot of pipeline internal filtration medium ceramic filter plate), these small particles will cause blockage of filter media lose permeability so that the filtering effect of variation, in order to reduce the possibility of blockage, ceramic filter will enter the backwash (this process is like a water jet device). Ceramic filter backwash is through the pressure of water, these small particles plug discharge ceramic filter board.

- Q: Why should filter core be used in backwash of ceramic filter?

- Ceramic filter recoil stage is with certain pressure of clean water from the inside out washing ceramic filter plate, the outer aperture ceramic filter plate from inside is gradually reduced, such as flushing water and unclean inside contain impurities that may block ceramic filter board, other structures in the recoil stage of pollution. Such as recoil, water is not clean, you must go through the water filter cartridge to filter again, the choice of filter core, the higher the accuracy of filtration, the more clean water, but the filter is more likely to plug, scrap. Of course, the water is clean and contains little solids. The filter core is not easy to plug and even water filters can be removed.

- Q: What is the reason that the ceramic filter does not absorb mineral powder?

- The recoil pressure is regulated by the pump loop valve and the pressure regulating valve. In order to avoid frequent fluctuations in pressure and pressure within a short period of time, a buffer cylinder with a stabilizing effect is provided in the backwash pipe.

- Q: Ceramic filter cleaning, sulfuric acid cleaning

- Ceramic filter medium is ceramic, ceramic generally resistant to strong acid, alkali, cleaning, it is best to use nitric acid, hydrochloric acid next, not recommended to use sulfuric acid.

- Q: What is the reason that ceramic filter does not absorb mineral powder?

- In order to avoid frequent fluctuations in pressure and pressure within a short period of time, a buffer cylinder with a stabilizing effect is provided in the backwash pipe.

- Q: The vacuum of ceramic filter is not enough

- Maybe the vacuum meter is broken. It doesn't show or show the data is different from the actual data.It could be the source of the vacuum, the vacuum pump failure.Pipeline leakage: vacuum system connecting pipes (metal pipes or rubber pipes) corrosion, aging and water leakage.Distributor head leakage: wear or poor sealing.Leakage of ceramic plate: rupture of ceramic plate.Other reasons.

- Q: What is the reason that the whole ceramic filter does not attract ore?

- After the joint cleaning, 0~2 hours of suction effect may be good, 2~4 may drop slightly, 4 hours later will become worse and worse, or even suck. This case should first check the backwash water pressure (instantaneous maximum pressure should not be less than 0.08MPa) is to meet the requirements, should also advance down (to ensure normal and ultrasonic cleaning combined with nitric acid dosage sufficient) and prolong the cleaning time.

- Q: How should the static and dynamic sealing points of the ceramic filter be leaking?

- When the ceramic filter works, the operation may be as follows: 1. The feed is injected and the pulp is injected into the tank of the ceramic filter. 2, mixing system, ceramic filter stirring rake back and forth mixing, driven by mixing reducer. 3, spindle rotation, material level reached a certain range, through the spindle speed machine to drive the ceramic filter disk rotation.

Send your message to us

High Silica Ceramic Fiberglass Casting Filter Plate

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches