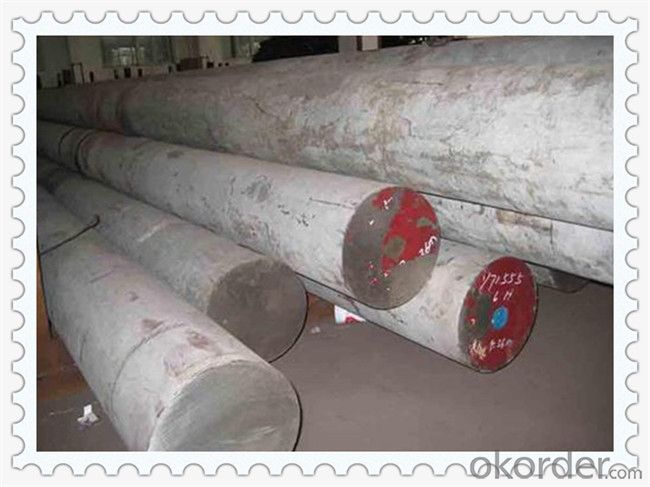

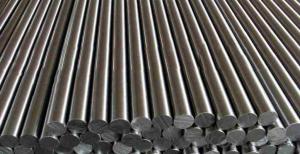

Hot Rolled Alloy Steel Round Bars

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Hot Rolled Alloy Steel Round Bars

1. Commodity: Round steel bar

3. Technical: Hot rolling

2. Length: Min. 5.8meter, according to requirement.

3. Diameter: 16mm-250mm

5. Packing: In Bundle or according to your requirements.

4. Standard: GB/T 3077-1999(42CrMo) ; JIS SCM440; DIN 42CrMo4 ; ASTM 4140 ; BS 708M40

No.1 Rolling Line / Billet Size 150*150mm

16 | 17 | 18 | 19 | 20 | 21 | 22 | 23 | 24 |

25 | 26 | 27 | 28 | 29 | 30 | 31 | 32 | 33 |

34 | 35 | 36 | 37 | 39 | 40 | 42 | 43 | 45.6 |

46 | 47 | 52 | 54 | 55 | 56 | 58 | 60 |

No.2 Rolling Line / Billet Size 180*220mm/ 260*300mm

62 | 63 | 64 | 65 | 66 | 67 | 68 | 69 | |

70 | 72 | 73 | 75 | 78 | 80 | 82 | 83 | 85 |

86 | 88 | 90 | 92 | 95 | 100 | 103 | 105 | 110 |

114 | 115 | 120 | 125 | 130 | 135 | 140 | 145 | 150 |

No.3 Rolling Line / Round Billet Size 350mm/450mm/600mm

90 | 95 | 100 | 105 | 110 | 115 | 120 | 125 | 130 |

140 | 150 | 160 | 170 | 180 | 190 | 200 | 210 | 220 |

230 | 240 | 250 |

- Q: What is the difference between a bright and a rough turned steel round bar?

- A bright turned steel round bar and a rough turned steel round bar differ primarily in their surface finish and the level of precision involved in their manufacturing processes. A bright turned steel round bar has a smooth, shiny surface finish. This is achieved by subjecting the bar to additional processes such as polishing or grinding after the initial turning operation. The bright surface finish gives the bar an aesthetically pleasing appearance and can also provide improved corrosion resistance. On the other hand, a rough turned steel round bar has a more textured surface finish. It is typically obtained directly from the turning operation without any additional processes to refine the surface. The rough surface finish may have visible tool marks and a slightly uneven texture. In terms of manufacturing precision, a bright turned steel round bar is typically more accurate and precise in terms of its dimensions and tolerances. The additional processes involved in achieving a bright surface finish also allow for tighter control over the bar's specifications. This makes bright turned bars suitable for applications where precise dimensions and tolerances are critical. In contrast, a rough turned steel round bar may have slightly looser tolerances due to the nature of the turning process and the lack of additional refining operations. However, the rough turned bars can still meet the requirements of many applications that do not require high precision. Overall, the choice between a bright and a rough turned steel round bar will depend on the specific application and the desired surface finish and precision.

- Q: Are steel round bars suitable for electrical conductivity?

- Steel round bars are not typically known for their electrical conductivity. Steel is a good conductor of heat but has relatively poor electrical conductivity compared to other metals such as copper or aluminum. This is because steel is primarily composed of iron, which is a poor conductor of electricity. However, the electrical conductivity of steel can be improved by adding certain alloying elements such as chromium or nickel. These alloying elements can enhance the electrical conductivity of steel, making it more suitable for specific applications where electrical conductivity is required. Nonetheless, if high electrical conductivity is a critical requirement, other materials like copper or aluminum are usually preferred over steel round bars.

- Q: What is hot rolling? What is called forging?

- By now most of the forging. The blank is placed in the fingerprint forging mold forging is that there is a free forging is the ancient drama often appear with a hammer blacksmith blacksmith

- Q: What are the advantages of using creep-resistant steel round bars?

- Using creep-resistant steel round bars in various applications has several advantages. Firstly, these bars offer exceptional resistance to high temperatures and prolonged stress exposure, making them ideal for high temperature environments such as power plants, boilers, and engines. Their ability to maintain their mechanical properties at elevated temperatures is a key advantage. Secondly, these round bars possess superior creep strength, allowing them to endure constant stress over extended periods without deformation or failure. This is particularly crucial in applications where components are subjected to continuous stress, such as pressure vessels or structural machinery. The high creep strength ensures the longevity and reliability of these components. Additionally, creep-resistant steel round bars exhibit excellent corrosion resistance. They are often alloyed with elements like chromium, molybdenum, or nickel, enhancing their ability to resist corrosion in harsh environments. This makes them suitable for industries like oil and gas, chemical processing, and marine applications where corrosion is a significant concern. Furthermore, these round bars possess favorable weldability, facilitating easy fabrication and assembly. They can be welded to other components without compromising their mechanical properties, making them versatile and cost-effective for construction projects. Moreover, these round bars offer dimensional stability and high hardness, guaranteeing that components maintain their shape and mechanical properties even under extreme conditions. This characteristic makes them suitable for applications requiring precision and accuracy, such as aerospace and automotive industries. In conclusion, the advantages of using creep-resistant steel round bars include their ability to withstand high temperatures, superior creep strength, corrosion resistance, weldability, dimensional stability, and high hardness. These advantages make them the preferred choice for various industries where reliability, longevity, and performance under harsh conditions are essential considerations.

- Q: What are the advantages of using nickel-molybdenum alloy steel round bars?

- Nickel-molybdenum alloy steel round bars offer numerous benefits: 1. They possess exceptional strength and durability, making them suitable for high-stress applications. They can withstand heavy loads and ensure long-lasting performance. 2. The addition of nickel enhances their resistance to corrosion, making them ideal for use in industries exposed to chemicals or moisture, such as oil and gas or marine applications. 3. These round bars exhibit excellent heat resistance, allowing them to maintain their mechanical strength and structural integrity in high-temperature environments. This makes them suitable for heat exchangers or power generation equipment. 4. They are easily machinable and can be customized according to project requirements. This versatility makes them adaptable to different applications. 5. They have good weldability, making them convenient for manufacturing processes and construction projects. They can be easily joined to other components or structures using standard welding techniques. 6. Despite their exceptional properties, nickel-molybdenum alloy steel round bars are relatively cost-effective compared to other high-performance alloys. This makes them a cost-efficient choice without compromising quality. In summary, nickel-molybdenum alloy steel round bars offer high strength, corrosion resistance, temperature resistance, machinability, weldability, and cost-effectiveness. These properties make them the preferred choice for various industries and applications that require superior performance and durability.

- Q: Can steel round bars be used for making fasteners or bolts?

- Certainly! The utilization of steel round bars is viable for the production of fasteners and bolts. Steel is widely employed as a material for these components due to its exceptional robustness, longevity, and resistance against corrosion. The round bars, crafted from steel, can be effortlessly manipulated and threaded, enabling the creation of an array of fasteners and bolts such as screws, nuts, and threaded rods. The selection of the precise steel grade hinges upon the specific application and desired strength properties. Nevertheless, it is imperative to bear in mind that the manufacturing process and stringent quality control are paramount in guaranteeing the dependability and performance of the end product.

- Q: How do steel round bars compare to concrete round bars?

- Steel round bars are typically stronger and more durable than concrete round bars. Steel has a higher tensile strength and can withstand greater loads and stresses. Concrete round bars, on the other hand, are more commonly used for their resistance to corrosion and fire. Both materials have their own advantages and applications, but steel round bars are generally preferred for their superior strength and versatility in various construction projects.

- Q: What are the typical price ranges for steel round bars?

- The price of steel round bars can differ depending on multiple factors, such as the steel type, diameter, length, and quantity purchased. Generally, common carbon steel grades can be priced between $1 and $5 per foot. However, specialty and high-grade steel round bars can have higher prices, ranging from $5 to $20 per foot or more. Moreover, larger diameter or longer length steel round bars may also be more expensive due to increased material and manufacturing costs. It is important to note that these price ranges are approximate and can vary depending on market conditions, supplier pricing, and other factors. To obtain an accurate price range, it is advisable to contact steel suppliers or distributors for specific quotes based on your requirements.

- Q: What are the different types of steel round bar surface finishes for improved lubricity?

- Some common types of steel round bar surface finishes for improved lubricity include chrome-plating, nickel-plating, and black oxide coating. These finishes help to reduce friction and enhance the performance of the steel round bar in various applications.

- Q: What are the different testing methods used for steel round bars?

- There are several testing methods used for steel round bars to ensure their quality and suitability for various applications. These methods include: 1. Visual Inspection: This is the initial step of testing, where the bars are visually examined for any visible defects, such as cracks, surface irregularities, or improper dimensions. 2. Dimensional checks: Steel round bars undergo dimensional checks to verify their diameter, length, and straightness. Precise measurements are essential to meet the specified requirements. 3. Ultrasonic Testing: Ultrasonic waves are passed through the round bars to detect internal defects, such as cracks, voids, or inclusions. This method helps identify potential weaknesses that may affect the structural integrity of the bars. 4. Magnetic Particle Inspection: This method uses a magnetic field and magnetic particles to detect surface and near-surface defects like cracks, seams, or laps. It is particularly useful in ferromagnetic materials such as steel. 5. Dye Penetrant Inspection: This technique involves applying a colored dye to the surface of the round bars and then wiping it off. The dye penetrates into any surface cracks or defects, making them visible under ultraviolet light. 6. Hardness Testing: This test measures the hardness of the steel round bars using methods like Rockwell or Brinell scales. It helps determine the material's ability to withstand external forces and ensures it meets the required hardness specifications. 7. Tensile Testing: Tensile strength testing is conducted to measure the maximum load a steel round bar can bear before it breaks. This test helps evaluate the material's strength and ductility. 8. Chemical Analysis: Chemical analysis is performed to determine the composition of the steel round bars, including the presence of elements like carbon, manganese, sulfur, phosphorus, and others. It ensures that the steel meets the required chemical composition standards. These testing methods are crucial in ensuring the quality, reliability, and compliance of steel round bars with industry standards and customer requirements. It is essential to perform a combination of these tests to ensure the overall quality and performance of the steel round bars in different applications.

Send your message to us

Hot Rolled Alloy Steel Round Bars

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords