High Quality Stainless Steel Profile with Better Prices

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Introduction of High Quality Stainless Steel Profile:

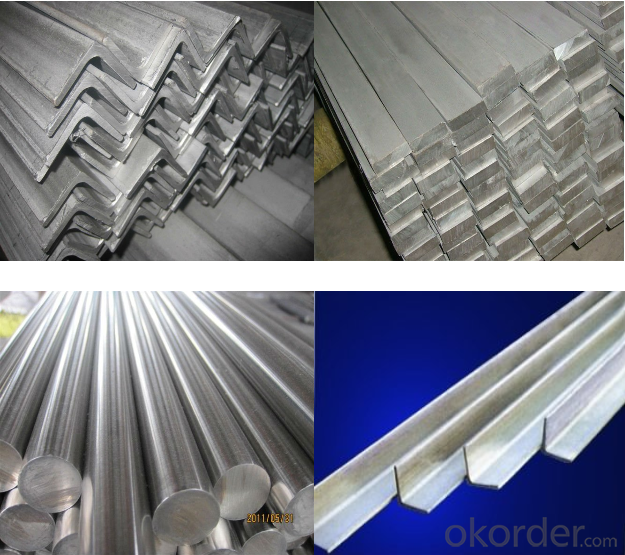

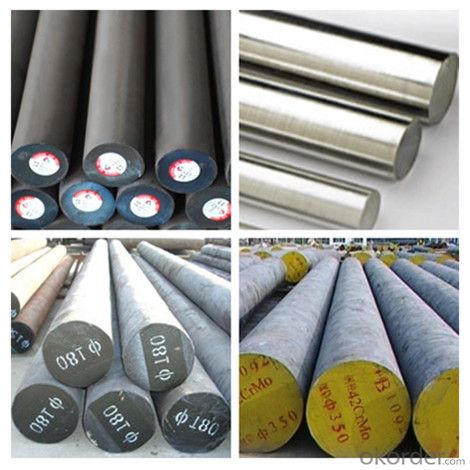

Our Stainless Steel products including the stainless steel sheet/plate, stainless steel coil, stainless steel rod/bar, stainless steel angle, stainless steel strip, stainless steel flat, carbon steel products and alloy steel materials. It also can supply the processing of surface, like No.4, BA, HL, SB, 8K, and so on.

Loading Quantity of High Quality Stainless Steel Profile: 25 Tons/20FCL.

Grade of High Quality Stainless Steel Profile: 201, 306, 316 Etc.

Delivery Time of High Quality Stainless Steel Profile: 20 days Per Container.

Application of High Quality Stainless Steel Profile:

| Finish | Thickness | Characteristics | Applications |

| No. 1 | 3.0mm~50.0mm | Finished by hot-rolling, annealing and pickling, characterized by white pickled surface | Chemical industry equipment, Industrial tanks |

| No. 2B | 0.3mm~6.0mm | Finished by heat treatment, pickling after cold rolling, followed by skin pass line to be more brighter and smooth surface | General Application Medical Instruments,Tableware |

| No. BA (Bright Annealed) | 0.5mm~2.0mm | Bright heat treatment after cold rolling | Kitchen utensil, kitchen ware,architectural purpose |

| No. 4 | 0.4mm~3.0mm | Polishing with No. 150 to No.180 mesh abrasivesThe most popular finishes | Milk & Food processing acilities, Hospital Equipment, Bath-tub |

| HL(Hair Line) | 0.4mm~3.0mm | Finished by continuous linear polishing | Architectural purposes, escalators, kitchen ware vehicles |

Packaging & Delivery of High Quality Stainless Steel Profile

| Packaging Detail: | standard seaworthy export package or as customers required |

| Delivery Detail: | Normally according to the order quantity or upon negotiation. |

Specification of High Quality Stainless Steel Profile:

1).Standard : GB,ASTM,AISI,JIS,SUS,EN

2).Material : 304,304L,304N,304LN,301,305,309S,310S,316,316L,316N,316LN,316Ti,

317,317L,321,347,201,202

3).Outside Diameter: From 4mm to 2500mm(1/8''inch-120''inch)

4).Wall Thickness : Sch5S-SchXXS(1mm-150mm)

5). Length : 3m,4m,5.8m,6m,12m or as required

6). Chemical composition:

7).Surface :Annealing ,polish,pickling,bright ,sand blast ,etc

8).Packing: 1.plastic cap with both ends 2.steel strip bundled package3.wooden case,wooden

pallet package4.container or bulk 5. as customers' requestment

9).Application:petroleum ,chemical industry,bolier ,heat exchange,high temperature

resistant transmission fluid pipe in power station,ship with pressure pipe,construction

and so on

FAQ

Q: CAN YOU PROVIDE MILL TEST CERTIFICATE?

A: YES! Mill Test Certificate for High Quality Stainless Steel Profile are available.

Q: CAN YOU MAKE DDQ (DEEP DRAWING QUALITY)?

A: YES. Our material has been widely used for producing Stainless Steel Pots and Stainless Steel Sinks, which have strict request for good deep drawing quality.

Q: HOW TO GET A SAMPLE?

A: FREE samples for High Quality Stainless Steel Profile are available for your checking and testing. And to get free samples, you need to send us you detailed receiving address (including post code) and your DHL/FedEx/UPS account for collecting samples, courier cost will be paid in your side.

- Q: What does "80 wire" stainless steel plate mean? How much more expensive than the average stainless steel plate?

- 80 silk is 0.8MM thick stainless steel plate, the price is almost the same

- Q: What's the difference between 304 stainless steel and 314?

- 304 stainless steel is a universal stainless steel material: 314 stainless steel; high temperature oxidation resistance and strong mechanical properties; high heat resistant stainless steel, and 314 austenitic stainless steel, high temperature oxidation resistance and creep resistance. 314 stainless steel used in furnace tube difference

- Q: What are the common uses of stainless steel sheets?

- Stainless steel sheets have a wide range of common uses due to their durability, corrosion resistance, and aesthetic appeal. Some of the most common applications of stainless steel sheets include kitchen appliances, automotive components, industrial equipment, construction materials, and decorative purposes.

- Q: What is the density of stainless steel sheets?

- The density of stainless steel sheets can vary depending on the specific grade and thickness of the sheet. However, on average, stainless steel sheets have a density of about 8,000 kilograms per cubic meter (kg/m³) or 8 grams per cubic centimeter (g/cm³). This high density is one of the reasons why stainless steel is known for its strength and durability.

- Q: How do you form stainless steel sheets into different shapes?

- Stainless steel sheets can be formed into different shapes through various processes such as bending, rolling, and welding. The specific method used depends on the desired shape and the thickness of the stainless steel sheet. Bending is a common method used to form stainless steel sheets into shapes such as cylinders or boxes. This process involves clamping the sheet between a punch and a die and applying force to create the desired bend. The angle and radius of the bend can be controlled by adjusting the pressure and the distance between the punch and die. Rolling is another technique employed to form stainless steel sheets into curved or cylindrical shapes. This process involves passing the sheet through a set of rollers, which gradually bend the material into the desired shape. The diameter and curvature of the final shape can be adjusted by changing the spacing and alignment of the rollers. For more complex shapes, welding is often used in conjunction with bending or rolling. In this process, multiple stainless steel sheets are joined together using heat and pressure to create the desired form. This allows for the creation of intricate shapes, such as cones or irregular geometries. In addition to these methods, specialized equipment such as hydraulic presses or hydroforming can also be utilized to form stainless steel sheets into different shapes. These techniques involve applying high pressure or fluid pressure to the sheet, resulting in deformation and the desired shape. It is important to note that forming stainless steel sheets requires skilled operators and precise machinery to ensure accuracy and quality. Additionally, the properties of the stainless steel, such as its thickness and composition, can also influence the feasibility and success of the forming process.

- Q: What are the different types of surface finishes for stainless steel sheets?

- Stainless steel sheets come in a variety of surface finishes, each with its own unique characteristics and appearances. Here are some of the most commonly used finishes: 1. The No.1 Finish, also known as hot rolled or annealed finish, is the most basic stainless steel finish. It has a rough, dull appearance with visible grain lines. This finish is typically used for industrial applications where aesthetics are not a priority. 2. The No.2B Finish is achieved by cold rolling the stainless steel sheet and then annealing it in a controlled atmosphere. This results in a bright, smooth finish with a semi-reflective appearance. It is often used for kitchen appliances, decorative trim, and architectural purposes. 3. The No.4 Finish is obtained by brushing the stainless steel sheet with abrasive materials, giving it a uniform, satin-like appearance. It is popular in commercial kitchens, elevator panels, and decorative applications that require a visually appealing and easy-to-clean surface. 4. The No.8 Mirror Finish is the most reflective surface finish available for stainless steel sheets. It involves polishing the surface to a mirror-like shine using progressively finer abrasives. This finish is commonly seen in decorative applications like architectural features, automotive trim, and jewelry. 5. The Hairline Finish is achieved by sanding the stainless steel sheet with fine abrasives in a consistent linear pattern. This creates a textured, brushed appearance and is often used for decorative purposes such as wall cladding, furniture, and signage. 6. The Bead Blasted Finish is achieved by bombarding the stainless steel sheet with small glass beads at high pressure, resulting in a uniform, matte texture. It is commonly used in architectural applications like column covers, elevator doors, and facade panels. These are just a few examples of the different surface finishes available for stainless steel sheets. Each finish offers its own visual effects, textures, and levels of reflectivity. The choice of finish depends on the desired aesthetic, functionality, and requirements of the application.

- Q: Are stainless steel sheets good for oil and gas equipment?

- Yes, stainless steel sheets are excellent for oil and gas equipment. Stainless steel is known for its exceptional resistance to corrosion, making it highly suitable for use in the oil and gas industry where exposure to harsh environments, chemicals, and high temperatures is common. Stainless steel sheets have superior strength and durability, ensuring they can withstand the demanding conditions in oil and gas equipment. Additionally, stainless steel sheets are easy to clean and maintain, which is crucial in industries that require strict hygiene standards. Their resistance to heat and pressure further enhances their suitability for oil and gas equipment. Overall, stainless steel sheets are a reliable and practical choice for the construction of oil and gas equipment, ensuring long-lasting performance and minimal maintenance requirements.

- Q: Can stainless steel sheets be used for architectural columns?

- Yes, stainless steel sheets can be used for architectural columns. Stainless steel is a highly durable and versatile material that offers excellent resistance to corrosion, making it suitable for both indoor and outdoor applications. The sleek and modern appearance of stainless steel also adds an aesthetic appeal to architectural designs. Additionally, stainless steel sheets can be customized to various sizes and shapes, allowing for flexibility in column design. Whether it is for residential, commercial, or industrial projects, stainless steel sheets are a popular choice for architectural columns due to their strength, longevity, and visual appeal.

- Q: How do stainless steel sheets compare to other types of metal sheets?

- Stainless steel sheets possess numerous advantages that distinguish them from alternative metal sheets. Firstly, stainless steel exhibits a high level of resistance to corrosion, rendering it an optimal selection for applications where durability and longevity are of utmost importance. Unlike other metals, stainless steel does not readily rust or stain, thereby guaranteeing the preservation of its appearance and functionality even in challenging environments. Secondly, stainless steel sheets are renowned for their strength and robustness. They possess a significant tensile strength, enabling them to endure heavy loads without undergoing bending or warping. This attribute renders stainless steel sheets suitable for a wide array of applications, including the construction, automotive, and manufacturing industries. Another notable advantage of stainless steel sheets lies in their hygienic properties. Stainless steel is non-porous and non-absorbent, facilitating easy cleaning and maintenance. Additionally, it exhibits resistance to bacterial growth, making it a favored choice for medical equipment, food processing facilities, and kitchen appliances. Furthermore, stainless steel sheets offer exceptional heat resistance. They can withstand high temperatures without compromising their structural integrity or developing any deformities, making them suitable for applications involving extreme heat or thermal cycling. Lastly, stainless steel sheets are available in a variety of finishes and textures, granting versatility in terms of design options. Whether one prefers a polished, brushed, or matte finish, stainless steel allows for customization to fulfill any aesthetic requirement. In conclusion, stainless steel sheets surpass other types of metal sheets due to their exceptional resistance to corrosion, strength, hygienic properties, heat resistance, and aesthetic versatility. These qualities establish stainless steel sheets as the preferred choice for numerous industries, ensuring durability, reliability, and longevity across various applications.

- Q: How do you prevent crevice corrosion on stainless steel sheets?

- To prevent crevice corrosion on stainless steel sheets, it is important to ensure proper cleaning and maintenance. Regularly inspect the sheets for any signs of damage or corrosion and promptly address any issues. Avoid leaving stagnant water or debris in crevices or gaps as they can promote corrosion. Applying protective coatings, such as paints or sealants, can also help prevent crevice corrosion. Additionally, using stainless steel grades that are more resistant to crevice corrosion, such as 316 or 317, can be beneficial in preventing this type of corrosion.

Send your message to us

High Quality Stainless Steel Profile with Better Prices

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords