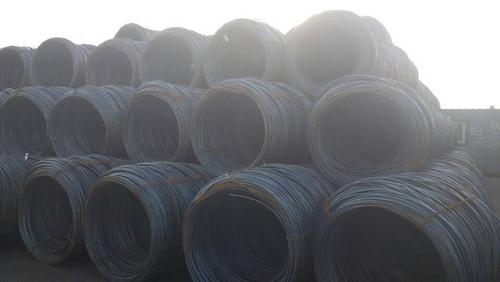

Steel Wire Rod with High Quality

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 5000MT m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Steel Wire Rod with High Quality at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to African, South American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Steel Wire Rod with High Quality are ideal for structural applications and are used in reinforcement of reinforced concrete and welded structure or reprocessed (Roberts, nails etc) materials, especially used to produce wire drawing, welding electrode, nails, spring, electronic, precise machinery parts and so on.

Product Advantages:

OKorder's Steel Wire Rod with High Quality are durable, strong, and wide variety of sizes.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Manufacture: Hot rolled

Grade: Q195 – 235

Size:5.5mm, 6.5mm, 8mm, 10mm, 12mm

Certificates: ISO, SGS, BV, CIQ

Packaging: Export packing, nude packing in coil

Coil weight:1.95-2.05MT

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will arrange production. The normal sizes with the normal grade can be produced within one month. The specific shipping date is dependent upon international and government factors, the delivery to international main port about 45-60days.

Images:

- Q: What are the factors that affect the corrosion resistance of steel wire rod?

- The factors that affect the corrosion resistance of steel wire rod include the composition of the steel, the presence of impurities or alloying elements, the surface condition of the wire rod, the environmental conditions such as humidity and temperature, and the presence of corrosive agents like water or chemicals. Additionally, the protection measures applied to the wire rod, such as coatings or galvanization, also play a significant role in enhancing its corrosion resistance.

- Q: What are the different transportation methods for steel wire rod?

- The different transportation methods for steel wire rod include trucking, rail transportation, and shipping via cargo vessels.

- Q: What are the common industry training programs for steel wire rod?

- Some common industry training programs for steel wire rod include courses on wire drawing techniques, quality control in wire rod manufacturing, safety protocols for handling and operating wire rod machinery, and metallurgical aspects related to wire rod production. These programs aim to equip individuals with the necessary knowledge and skills to effectively work with steel wire rod in various industrial applications.

- Q: What are the main factors affecting the product lifespan of steel wire rod?

- The main factors affecting the product lifespan of steel wire rod include the quality of the raw materials used, the manufacturing process, the environmental conditions it is exposed to, and the maintenance and handling practices during its usage.

- Q: How are steel wire rods used in the manufacturing of piano strings for musical instruments?

- Steel wire rods are used in the manufacturing of piano strings for musical instruments by being drawn through a series of dies to achieve the desired thickness and strength. These wire rods are then wound tightly around a core wire to create the piano string. The high tensile strength of steel wire makes it ideal for withstanding the tension required to produce the desired pitch and resonance in a piano.

- Q: What are the different types of wire ropes made from steel wire rod?

- The different types of wire ropes made from steel wire rod include galvanized wire ropes, stainless steel wire ropes, and non-rotating wire ropes.

- Q: How is steel wire rod used in the manufacturing of wire for suspension systems in buildings?

- Steel wire rod is a crucial component in the manufacturing of wire for suspension systems in buildings. It serves as the raw material from which the wire is produced. The steel wire rod undergoes a series of processes such as cleaning, drawing, and annealing to transform it into high-quality wire with specific properties like strength and flexibility. This wire is then utilized in the construction of suspension systems, providing support and stability to various building structures such as ceilings, bridges, and curtain walls.

- Q: What are the advantages of using steel wire rod in automotive applications?

- There are several advantages of using steel wire rod in automotive applications. Firstly, steel wire rod is known for its high strength and durability, making it capable of withstanding heavy loads and providing structural integrity to automotive components. Secondly, steel wire rod offers excellent flexibility, allowing it to be easily shaped and formed into various parts and components, thereby enhancing design and manufacturing possibilities. Additionally, steel wire rod has good corrosion resistance, ensuring that automotive parts remain protected and functional over an extended period of time. Lastly, steel wire rod is cost-effective and readily available, making it a popular choice in automotive applications.

- Q: How is steel wire rod used in the manufacturing of wire forms for household appliances?

- Steel wire rod is used in the manufacturing of wire forms for household appliances as it provides strength and durability to the final product. The wire rod is first drawn and shaped into the desired form, such as hooks or grids, which are then incorporated into various components of household appliances. The wire forms not only enhance the structural integrity of the appliances but also serve functional purposes, such as holding or supporting other parts. Overall, steel wire rod is crucial in creating reliable and efficient wire forms for household appliances.

- Q: What are the common applications of cold drawn steel wire rod?

- Cold drawn steel wire rod is commonly used in a variety of applications due to its unique properties and characteristics. Some of the common applications of cold drawn steel wire rod include: 1. Wire products manufacturing: Cold drawn steel wire rod is extensively used in the manufacturing of various types of wire products such as nails, screws, springs, cables, and wire mesh. The cold drawing process enhances the strength, ductility, and surface finish of the wire, making it ideal for these applications. 2. Automotive industry: Cold drawn steel wire rod is widely used in the automotive industry for the production of parts like suspension springs, seat springs, engine valve springs, and drive shafts. The high strength and excellent fatigue resistance of cold drawn steel wire make it suitable for these critical components. 3. Construction sector: Cold drawn steel wire rod is used in the construction sector for reinforcing concrete structures. The wire is commonly used in the form of welded wire mesh or as individual reinforcement bars. The cold drawing process improves the wire's tensile strength, making it suitable for withstanding high loads and providing structural stability. 4. Electrical industry: Cold drawn steel wire rod is utilized in the electrical industry for the production of electric cables, power transmission cables, and magnet wire. The wire's excellent electrical conductivity and mechanical properties make it suitable for these applications. 5. Manufacturing equipment: Cold drawn steel wire rod is used in the manufacturing of various equipment, such as machinery, tools, and equipment components. The wire's high strength, dimensional accuracy, and surface finish make it suitable for producing precise and reliable components. 6. Furniture manufacturing: Cold drawn steel wire rod is commonly used in the furniture industry for manufacturing springs used in mattresses, sofas, and chairs. The wire's excellent resilience and durability are essential for providing comfort and longevity to furniture products. 7. Agriculture sector: Cold drawn steel wire rod is extensively used in the agriculture sector for applications such as fencing, vineyard trellises, and animal enclosures. The wire's strength, corrosion resistance, and flexibility make it suitable for withstanding outdoor exposure and providing long-lasting support. In conclusion, cold drawn steel wire rod finds widespread applications in various industries due to its exceptional properties. These applications include wire products manufacturing, automotive industry, construction sector, electrical industry, manufacturing equipment, furniture manufacturing, and agriculture sector.

Send your message to us

Steel Wire Rod with High Quality

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 5000MT m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords