High Quality of Cold Rolled Steel Coil from China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Cold Rolled Steel Description:

The raw material of cold rolled steel coil/sheet is high quality hot rolled product, and after pickling continuous rolling, degreasing, annealing,skin pass,slitting and cut to length line etc. Along with it many kinds of new technology and new process of global cold rolling production have been applied. Therefore the quality of the goods could be guaranteed. The product is widely used in outdoor and interior decoration, furnishing manufacturing, home appliance, automobile etc.

2.Main Features of the Cold Rolled Steel:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

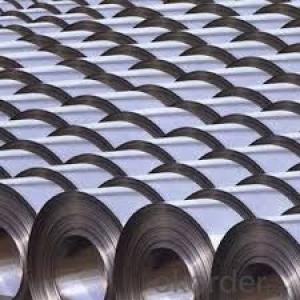

3.Cold Rolled Steel Images

4.Cold Rolled Steel Specification

Standard:AISI,ASTM,DIN,GB,JIS,JIS G3302 ASTM 653M EN10142

Grade: Q195~Q345

Thickness: 0.16mm~1.5mm,0.16-1.5mm

Width: 1250,600-1250mm

Coil weight:3-12 MT

Coil ID:508/610mm

Chemical composition:

C | Si | Mn | Cr | Ni | P | S |

0.150 | 0.476 | 11.231 | 12.50 | 0.900 | 0.039 | 0.010

|

5.FAQ of Cold Rolled Steel

We have organized several common questions for our clients,may help you sincerely:

1.How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

- Q: Are the steel sheets heat-resistant?

- Yes, steel sheets are heat-resistant. Steel is known for its high melting point, which makes it a suitable material for applications that involve exposure to high temperatures. It can withstand heat without warping or losing its structural integrity. However, the exact level of heat resistance may vary depending on the specific type of steel and its composition. Some steel alloys are specifically designed to have even higher heat resistance, making them suitable for use in industries such as aerospace, automotive, and construction, where high-temperature environments are common.

- Q: How do you repair damaged steel sheets?

- To repair damaged steel sheets, the process typically involves identifying the extent of the damage, cleaning the affected area, and then either welding or patching the damaged section. Welding is commonly used for minor damages, while patching with epoxy or steel patches is suitable for more significant damage. Additionally, proper surface preparation, such as sanding or grinding, is crucial before applying any repair method to ensure a successful and durable repair of the steel sheets.

- Q: How are steel sheets tested for quality and performance?

- Steel sheets are tested for quality and performance through various methods such as mechanical testing, chemical analysis, and visual inspection. Mechanical testing involves subjecting the steel sheets to stress, tension, and hardness tests to determine their strength and durability. Chemical analysis is conducted to assess the composition and purity of the steel, ensuring it meets the required standards. Visual inspection checks for any surface defects, such as cracks, scratches, or unevenness in the steel sheets. These comprehensive testing methods ensure that steel sheets meet the desired quality and performance criteria.

- Q: How are steel sheets stored to prevent damage?

- Steel sheets are typically stored in a dry and climate-controlled environment to prevent damage. They are stacked flat and evenly, with proper support between each sheet to avoid warping or bending. Additionally, protective coverings such as plastic sheets or cardboard are often used to shield the steel sheets from moisture, dust, and other potential sources of damage.

- Q: How do steel sheets handle bending or flexing?

- Steel sheets are highly malleable and can handle bending or flexing quite well. Due to their inherent strength and ductility, steel sheets can be easily bent or flexed without breaking or cracking, making them ideal for various applications in construction, manufacturing, and engineering industries.

- Q: Can steel sheets be used for storage tanks?

- Yes, steel sheets can be used for storage tanks. Steel is a strong, durable, and corrosion-resistant material, making it suitable for containing various materials and liquids in storage tanks.

- Q: How are steel sheets tested for hardness?

- Various methods are employed to test the hardness of steel sheets, with one of the most commonly used being the Rockwell hardness test. In this test, a known force is applied to the steel sheet's surface using a small indenter, typically a diamond or a hardened steel ball. The resulting depth of penetration is then measured and standardized to determine the hardness value. Another method utilized is the Brinell hardness test, which involves pressing a hardened steel ball into the steel sheet's surface under a specific load. The diameter of the resulting indentation is measured and used to calculate the hardness value. Furthermore, the Vickers hardness test employs a pyramid-shaped diamond indenter. Similar to the Rockwell test, this method measures the indentation produced, but instead of focusing on the depth of penetration, it determines the hardness value by measuring the diagonal length of the indentation. These hardness tests yield significant insights into the mechanical properties of steel sheets, including their resistance to deformation and wear. By ensuring that the steel sheets meet the required specifications, the test results enable their use in various applications where hardness plays a critical role.

- Q: Bathroom washing machine, galvanized steel and color steel which good?

- Infiltration of zinc is the function of zinc atoms to the steel parts, the steel plate has undergone a qualitative change, even if it does not scratch Yi Shengxiu

- Q: How do steel sheets perform in terms of abrasion resistance?

- Steel sheets generally have good abrasion resistance due to their hardness and durability. They can withstand friction and wear caused by rubbing or scraping against other surfaces, making them suitable for applications requiring resistance to wear, such as in construction, manufacturing, and automotive industries.

- Q: What are the different thickness options for steel sheets?

- The thickness options for steel sheets can vary depending on the specific requirements, but commonly available options range from thin gauges like 30 gauge (0.012 inches) to thicker ones such as 10 gauge (0.134 inches).

Send your message to us

High Quality of Cold Rolled Steel Coil from China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords