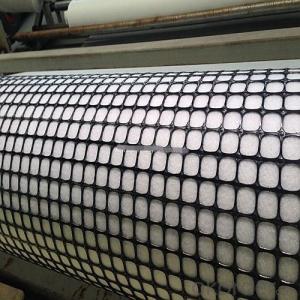

Uniaxial and Biaxial Geogrids Reinforced Composite Geotextile with Membrane and Nonwoven Geotextiles for Civil Engineering

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m

- Supply Capability:

- 50000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

composite geotextile with membrane,nonwoven Geotextiles In Civil Engineering

1) Weight:100gsm-1500gsm

2) width:Within 8m

3)le

composite geotextile with membrane,nonwoven Geotextiles In Civil Engineering

Product Description

Geotextiles also called geotextile fabrics, it’s permeable geosynthetics made of synthetic fibers through woven or needle punched.

Geotextiles including :needle punched nonwoven geotextile , filament woven geotextile , split yarm PP woven geotextile,composite geotextile + geomembrane,Geotextile Bags.

1) Staple fibers needle punched non woven geotextile

The geotextile is made of polypropylene staple fibers on cross-laying equipment and needle punched equipment.

It owns the advantages of acid and alkali resistance, erosion resistance, aging resistance, large strength, stable size, good filtrability etc.

2 ) Filament non woven geotextile

Filament geotextile has features as follows: High strength, good capacity of elongation and high biology tolerance, alkali tolerance, acidity tolerance, weather resistance good filtration and fine drainage capacity etc. Also it is of low cost, easy in construction and use effects.

3) Geotextile membrane:

1. One piece of geotextile and one piece of membrance :Wight:100~1000/m2 , Thickness : 0.1~1.5mm

2. Two piece of geotextile and one piece of membrance :Wight:80~600/m2 , Thickness : 0.2~1.5mm

3. One piece of geotextile and two piece of membrance : Wight:100~1000/m2 , Thickness : 0.1~0.8mm

4. multi-layers :Wight:100~1000/m2 , Thickness : 0.1~0.8mm

Flexibility is good,except of geotextile's isolation,drainage, reinforcement,protective functions,It is also impermeable.

Usage: Widely used in dam,traffic tunnel,road,airport,drainage,housing,environmental protection and other fields for waterproof protection,reinforcement etc.

- Q: Can geogrids be used in environmental containment systems?

- Yes, geogrids can be used in environmental containment systems. Geogrids are often used as reinforcement in these systems to prevent soil erosion and maintain the stability of containment structures, such as landfills or retention ponds. They enhance the overall strength and performance of the containment system, making them an effective solution for environmental protection.

- Q: Can geogrids be used in reinforcement of embankments?

- Yes, geogrids can be used in the reinforcement of embankments. Geogrids are commonly used in civil engineering projects to enhance the stability and strength of soil structures, such as embankments. They are designed to distribute loads and provide support, reducing the potential for settlement and slope failure. By incorporating geogrids into the embankment design, the overall performance and durability can be improved, making them a suitable choice for reinforcement.

- Q: What are the specifications for geogrid installation?

- The specifications for geogrid installation typically include factors such as the type and strength of the geogrid material, the required overlap or seam allowance, the recommended depth of installation, the recommended slope angle for placement, and any specific site preparation or soil compaction requirements. Other factors to consider may include the desired load-bearing capacity, the expected lifespan of the geogrid, and any additional reinforcement or anchoring methods necessary. It is important to consult the manufacturer's guidelines and any relevant engineering or construction standards for specific specifications and recommendations.

- Q: Are geogrids resistant to extreme temperatures?

- Yes, geogrids are generally resistant to extreme temperatures. They are designed to withstand hot and cold weather conditions without significant degradation, making them suitable for a wide range of environmental applications.

- Q: How do geogrids prevent cracking in asphalt pavements?

- Geogrids prevent cracking in asphalt pavements by distributing and reinforcing the load from traffic and reducing tensile stresses within the pavement. Additionally, they enhance the overall structural integrity and stability of the pavement by minimizing differential settlements and controlling reflective cracking.

- Q: Can geogrids be used in stormwater management systems?

- Yes, geogrids can be used in stormwater management systems. Geogrids are often utilized to reinforce and stabilize soil in stormwater management applications such as retaining walls, embankments, and erosion control measures. They can help improve the overall performance and longevity of stormwater management structures by enhancing soil stability and preventing erosion.

- Q: How do geogrids help in reducing the carbon footprint of a project?

- Geogrids help in reducing the carbon footprint of a project by providing reinforcement to soil, thereby reducing the need for excessive excavation and the use of concrete or other materials. This leads to a significant reduction in carbon emissions associated with production, transportation, and installation of such materials. Additionally, geogrids can enhance the stability and longevity of structures, reducing the need for maintenance and replacement, which further contributes to the reduction in carbon footprint.

- Q: Do geogrids provide reinforcement to geosynthetic asphalt liners in landfill covers?

- Yes, geogrids do provide reinforcement to geosynthetic asphalt liners in landfill covers.

- Q: Do geogrids increase the bearing capacity of soil?

- Yes, geogrids can increase the bearing capacity of soil. Geogrids are geosynthetic materials that are used to reinforce soil and improve its stability. By distributing the load more evenly, geogrids can enhance the load-bearing capacity of the soil, making it more suitable for construction or other heavy-duty applications.

- Q: How much is the overlap length of Geogrid

- The horizontal distribution of shear walls should be staggered staggered 500mm, lap length 1.2LaE.

Send your message to us

Uniaxial and Biaxial Geogrids Reinforced Composite Geotextile with Membrane and Nonwoven Geotextiles for Civil Engineering

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m

- Supply Capability:

- 50000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords