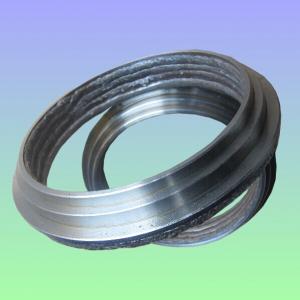

PM 230 Spectacle Wear Plate with Excellent Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Name: High Quatity PM 230 Spectacle Wear Plate

1. Specification

1. Material: Plate body S35C steel, tungsten carbide E5 grade ,

2. Lifetime: 30,000~80,000cbm

3. HRA≥86

4. Germany Welding rod used for hardfacing

5. tensile strength ≥ 2500 N/mm2

6. Application: trailer and trunk mounted Schwing Putzmeister Pump

Notes: total series of Concrete Pump Spectacle Wear Plate and Cutting Ring for different brand concrete pump (PUTZMEISTER, SCHWING, CIFA, SANY, ZOOMLION, IHI, KYOKUTO,Niigata Etc) available from us.

2. Application

Our High Quatity PM 230 Spectacle Wear Plate have been successfully exported to many countries from 1998, Our main markets as below: Middle East, Southeast Asia, America, Brazil, Italy, Russia, South Africa etc

Aiming at the largest concrete pump parts manufacturer, and reliable, professional supplier in China, we can supply concrete pump elbows, delivery pipes, casting or forging couplings, end rubber hoses, rubber pistons, tungsten wear plates, delivery cylinders, and other hydraulic parts, one stop service for your concrete pump parts and accessory business.

3. Package

Every 60pcs High Quatity PM 230 Spectacle Wear Plate put in one seaworthy wooden box, and 20 boxes in one 20feet container.

FAQ:

Q1: Why buy Materials & Equipment from us?

A1: All products have its ISO certifications, adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 10 to 30 workdays.

Q4: If we can produce some High Quatity PM 230 Spectacle Wear Plate according to customers request?

A4: Yes, we can produce High Quatity PM 230 Spectacle Wear Plate according to the difference country situations and different concrete pump to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5:We have overseas branches all-around of world, IF needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities &skilled personnel at site for training.

Image:

- Q: What is the function of a concrete pump hopper agitator shaft bearing?

- The primary function of the bearing on the agitator shaft of a concrete pump hopper is to offer support and facilitate smooth rotation. Typically constructed from strong materials like steel or bronze, the bearing is designed to endure substantial loads and vibrations. Its purpose is to minimize friction and prevent premature seizing or wear of the agitator shaft. Furthermore, the bearing aids in maintaining the alignment of the shaft, thereby ensuring efficient concrete mixing within the hopper. Overall, the bearing on the agitator shaft of a concrete pump hopper is essential for its reliable and consistent performance.

- Q: What is the function of a concrete pump hopper grate lever?

- The function of a concrete pump hopper grate lever is to control the opening and closing of the hopper grate on a concrete pump. The hopper grate is a metal grid that covers the hopper, which is the chamber where the concrete is loaded before being pumped. The lever allows the operator to easily manipulate the position of the grate, either opening it to allow concrete to flow into the hopper or closing it to prevent any debris or foreign objects from entering the pump system. This control is crucial for ensuring the smooth and efficient operation of the concrete pump, as any obstructions or contaminants in the hopper can potentially damage the pump or affect the quality of the pumped concrete. By using the hopper grate lever, the operator can maintain a steady flow of concrete into the pump and ensure that only clean and properly mixed concrete is being used. Additionally, the lever provides a safety measure, as it allows the operator to quickly close the grate in case of any emergencies or malfunctions. Overall, the concrete pump hopper grate lever plays a vital role in the proper functioning and maintenance of a concrete pump system.

- Q: How can one differentiate between genuine and counterfeit concrete pump spare parts?

- To differentiate between genuine and counterfeit concrete pump spare parts, one should consider several factors. Firstly, it is crucial to purchase spare parts from authorized and reputable dealers or manufacturers. Genuine parts are typically sold through official channels, ensuring their authenticity and quality. Secondly, one should carefully inspect the packaging and labeling of the spare parts. Genuine parts often have clear branding, product numbers, and proper packaging, while counterfeit parts may have inconsistent labeling or poor quality packaging. Additionally, examining the quality and durability of the spare parts is essential. Genuine parts are manufactured to meet strict standards and are more likely to be durable and reliable. Lastly, seeking professional advice or consulting with experts in the industry can provide valuable insights into identifying genuine concrete pump spare parts.

- Q: Can concrete pump spare parts be customized for specific pump models?

- Yes, concrete pump spare parts can be customized for specific pump models. Concrete pumps come in various sizes and designs, and each model may have unique specifications and requirements for its spare parts. To ensure compatibility and optimal performance, it is important to customize the spare parts according to the specific pump model. This customization can include dimensions, materials, and other technical specifications that are tailored to fit the particular pump model. By customizing the spare parts, it ensures a perfect fit and enhances the efficiency and longevity of the concrete pump. Additionally, customization allows for potential improvements or modifications to the original design, resulting in enhanced performance and durability of the pump. Therefore, it is crucial to work with reputable manufacturers or suppliers who can provide customized concrete pump spare parts for specific pump models.

- Q: What is the purpose of a concrete pump hydraulic accumulator bladder?

- The purpose of a concrete pump hydraulic accumulator bladder is to store and release hydraulic energy, resulting in smoother and more efficient operation of the concrete pump.

- Q: What are the different types of concrete pump hopper cylinders?

- There are primarily two types of concrete pump hopper cylinders: single-acting cylinders and double-acting cylinders. Single-acting cylinders have only one piston that pushes the concrete out of the hopper. On the other hand, double-acting cylinders have two pistons, one for pushing the concrete out and the other for bringing it back into the hopper.

- Q: When concrete is poured, how high can the concrete pump be put?

- General building pouring concrete, height of automobile pump for the arm length minus 20 meters (consider horizontal movement of pump truck, leaving the house distance consumed that is to say, the arm length) 40 meters long arm pump car is 20 meters high, 60 meters long arm pump car for the height of 40 meters

- Q: Are there any specific safety precautions while replacing concrete pump spare parts?

- There exists a variety of safety precautions that must be followed when replacing concrete pump spare parts. 1. Personal Protective Equipment (PPE) is of utmost importance and should be worn to safeguard against potential hazards. This includes safety goggles, gloves, a helmet, and steel-toed boots. 2. It is essential to adhere to proper lockout/tagout procedures prior to replacing any spare parts. This entails disconnecting and securing the power source to prevent accidental startup of the pump. 3. Before commencing the replacement process, inspect all tools and equipment for any indications of damage or defects. It is crucial to refrain from using faulty equipment, as it can pose significant safety risks. 4. When handling heavy spare parts, it is imperative to employ appropriate lifting techniques to prevent strain or injury. Ensure that proper assistance and equipment, such as cranes or forklifts, are available if necessary. 5. Maintain a clean and well-organized work area to prevent trips, slips, and falls. Remove any obstacles or debris that may jeopardize safety during the replacement process. 6. Only trained and authorized personnel should be involved in the replacement of concrete pump spare parts. They must possess a thorough understanding of the equipment and procedures to minimize the likelihood of accidents. 7. Always consult the manufacturer's guidelines and instructions when replacing spare parts. This will ensure that the process is executed safely and accurately. 8. It is vital to have a plan in place for potential emergencies, including fires or injuries. Make certain that fire extinguishers and first aid kits are easily accessible, and that all workers are familiar with their locations and usage. By adhering to these safety precautions, the risk of accidents, injuries, and damage can be significantly reduced when replacing concrete pump spare parts.

- Q: Can I get spare parts for concrete pump accessories like remote control systems?

- Yes, you can get spare parts for concrete pump accessories like remote control systems. Many manufacturers and suppliers of concrete pump accessories offer a range of spare parts for their products. These spare parts may include components for remote control systems such as buttons, switches, sensors, batteries, and transmitters. It is advisable to contact the manufacturer or supplier directly to inquire about the availability of spare parts for the specific model of remote control system you have. They will be able to provide you with the necessary information and assist you in obtaining the required spare parts.

- Q: How often should concrete pump remote control batteries be replaced?

- The replacement of concrete pump remote control batteries relies on several factors, including frequency of usage, battery quality, and environmental conditions. However, as a general rule, it is advisable to change the batteries every 6 to 12 months. This guarantees optimal functioning of the remote control and prevents unforeseen battery failures during crucial operations. Additionally, it is crucial to periodically assess battery performance and perform maintenance checks to ensure proper functionality.

Send your message to us

PM 230 Spectacle Wear Plate with Excellent Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords