HIGH QUALITY HOT ROLLED WIRE ROD SAE1008 SAE1018 SAE1006

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Specifications of Wire Rod SAE1008B:

Steel Grade: SAE1008B Standard: ASTM, GB

Diameter: 5.5mm, 6.5mm, 7mm,8mm,9mm,10mm,12mm,14mm

Type: Drawn Wire Alloy or Not: Alloy Brand Name: N-RIVER

Technique: Hot Rolled Place of Origin: China Mainland

Chemical Composition:

Please kindly find our chemistry of our material based on SAE1008B as below for your information

Grade | Chemical Composition (%) | |||||

C | Mn | S | P | Si | B | |

SAE1008B | 0.10max | 0.32max | 0.045max | 0.040max | 0.30max | 0.0008min |

Mechanical properties | ||||||

Yield strength(N/mm2) | Tensile strength(N/mm2) | Elongation (%) | ||||

≥195 | 350-380 | ≥32 | ||||

Usage and Applications of Wire Rod SAE1008B:

After hot-rolled the products shaped into coil and delivery as finished product, including round, square, rectangular, hexagonal and so on. Since most of the products are round, it is generally called wire rod. Carbon steel wire rod is widely used in construction and manufacturing. Carbon steel wire rod is mainly used for reinforcement of reinforced concrete and welded structure or reprocessed (roberts , nail, etc.) materials, especially used to produce wire drawing, welding electrode, nails, spring, electronic, precise machinery parts and so on.

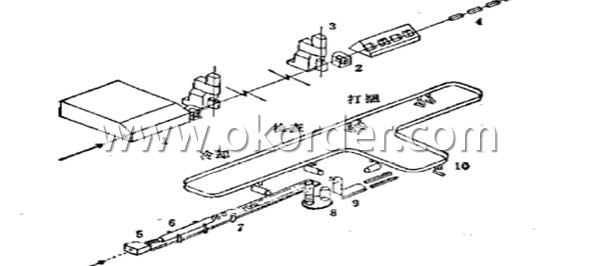

Production Process of Wire Rod SAE1008B:

1-Furnace 2-Roughing Mill 3-High-speed Finishing Mill 4-Water-cooled Device 5-Coiling Device

6-Cooling Device 7-Chain Conveyer 8-Spool Collecting Device 9-Spool Down Device 10-Hook Conveyer

Packaging & Delivery of Wire Rod SAE1008B:

Packaging Detail: products are packed in coil and then shipped by container or bulk vessel

Each coil weight: 2-3MT

Delivery Detail: within 45 days after received deposit or LC.

Label: to be specified by customer, generally, each bundle has 1-2 labels

Trade terms: CFR, CIF

Note:

1. Our products are produced according to national standard (GB), if not, supply according to national standards (GB) or agreement as customer required.

2. Other Grade and Standard carbon steel wire rod we can supply:

Grade: H08A, 30MnSi, 62B-82B

Standard: AISI, BS, JIS, DIN

The Minimum Order Quantity of these products is high, and need to be confirmed.

3. We can not only supply carbon steel wire rod; if you need anything about building materials, please contact us.

4. Please send us your detail specifications when inquire. We will reply to you as soon as possible. We sincerely hope we can establish a long stable business relationship.

- Q: How do steel angles contribute to the sustainability of transportation systems?

- Several ways contribute to the sustainability of transportation systems through the utilization of steel angles. To begin with, steel angles find wide use in constructing infrastructure, such as bridges, highways, and railway tracks. These structures boast a longer lifespan and necessitate fewer repairs and replacements compared to alternative materials. As a result, maintenance costs and resource consumption are reduced. Furthermore, steel angles possess exceptional durability and resistance to severe weather conditions. This quality ensures the longevity and safety of transportation systems. Consequently, the need for frequent repairs or replacements is minimized, thereby decreasing the overall environmental impact and carbon emissions associated with transportation infrastructure. In addition, steel angles possess a high strength-to-weight ratio, enabling the design of lighter and more fuel-efficient vehicles. Utilizing steel angles in the manufacturing process of automobiles, trains, and ships leads to reduced vehicle weight, thereby enhancing fuel efficiency and decreasing greenhouse gas emissions during operation. Moreover, steel angles can be easily recycled at the end of their lifecycle. Globally, steel is one of the most recycled materials, boasting a recycling rate of over 85%. By recycling steel angles, not only is the demand for virgin steel production reduced, but energy is also saved, and greenhouse gas emissions associated with extraction and manufacturing processes are decreased. Overall, the incorporation of steel angles in transportation systems promotes sustainability by fostering durability, decreasing maintenance needs, improving fuel efficiency, and enabling efficient recycling. These factors collectively contribute to minimizing the environmental impact and enhancing the long-term viability of transportation infrastructure.

- Q: Can steel angles be used for mezzanines or catwalks?

- Yes, steel angles can be used for mezzanines or catwalks. Steel angles are popular for these applications due to their strength and versatility. They provide structural support and can be easily bolted or welded together to create a sturdy framework for mezzanines or catwalks. Additionally, steel angles are available in various sizes and thicknesses, allowing for customization to meet specific design requirements. Overall, steel angles are a cost-effective and reliable choice for constructing mezzanines or catwalks in both commercial and industrial settings.

- Q: What is the maximum load capacity for a steel angle beam?

- The maximum load capacity for a steel angle beam depends on various factors such as the size and dimensions of the beam, the grade of steel used, and the specific application or intended use. Steel angle beams are commonly used in construction and structural applications for supporting loads, but the exact maximum load capacity can vary. It is important to consult engineering specifications, structural design codes, or consult with a structural engineer to determine the specific maximum load capacity for a steel angle beam in a particular scenario.

- Q: How do steel angles provide structural support?

- Steel angles provide structural support by distributing and transferring loads and forces in various structures. They are commonly used as braces or brackets to reinforce and stabilize beams, columns, and other members. The L-shaped design of steel angles allows them to resist bending and provide strength and rigidity to the structure. They can be bolted or welded to the main structural components, thereby increasing their load-carrying capacity and overall stability.

- Q: Can steel angles be used in stair construction?

- Yes, steel angles can be used in stair construction. Steel angles are commonly used as structural elements in staircases to provide support and stability. They can be used as stringers, which are the main load-bearing components of a staircase, or as brackets and supports for treads and handrails. Steel angles are known for their strength and durability, making them suitable for use in stair construction to ensure the safety and longevity of the staircase.

- Q: What does L50*4 angle mean in CAD?

- Angle called angle, the steel strip is perpendicular to each other on both sides into the corner. There are equal angles and unequal angles. The two sides of an equal angle steel are equal in width. The specifications are expressed in millimeters of edge width * edge width * edge thickness. Such as "30 x 30 x 3", that is 30 mm width equal angle, edge thickness of 3 mm.

- Q: What are the different types of steel angles used in signage structures?

- Signage structures commonly utilize various types of steel angles to provide structural support and stability. These angles ensure the signage remains secure and can endure different weather conditions. 1. Labeled as equal angles or L-shaped angles, these angles possess identical sides and are frequently employed in signage structures. They establish a robust and sturdy framework for the signage, enabling it to withstand external forces such as wind. 2. Unequal angles, as their name implies, feature sides of differing lengths. They are often utilized in signage structures where different sections of the signage necessitate varying levels of support. These angles can be customized to meet specific design requirements and enhance the stability of the signage. 3. Hollow Structural Sections (HSS) angles are steel angles with a hollow interior. Due to their lightweight nature and high strength-to-weight ratio, these angles are extensively used in signage structures. When constructing large and intricate signage structures, HSS angles are especially beneficial as they reduce overall weight and facilitate easier installation. 4. Corner angles are employed to fortify the corners of signage structures, providing additional support and preventing potential bending or warping. Typically crafted from thicker steel, these angles are designed to withstand significant stress and pressure. 5. Galvanized angles are steel angles coated with a layer of zinc to safeguard against rust and corrosion. They are commonly employed in outdoor signage structures exposed to moisture and other environmental elements. The galvanized coating guarantees the durability and longevity of the angles, hence extending the lifespan of the signage structure. Ultimately, the selection of steel angles for signage structures relies on factors such as signage size, design, expected load and stress, and environmental conditions. By choosing the appropriate type of steel angle, signage structures can be constructed to endure outdoor environments and provide enduring support for a variety of signage types.

- Q: What is the maximum length of a steel angle?

- The maximum length of a steel angle can vary depending on several factors such as the manufacturing process, the available raw materials, and the specific requirements of the project. However, in general, steel angles are typically available in standard lengths ranging from 20 feet to 40 feet. These lengths are commonly used for construction purposes and can be easily transported and installed on-site. It's important to note that customized lengths can also be fabricated based on specific project needs, but they may require additional time and cost. Therefore, it is recommended to consult with a steel supplier or manufacturer to determine the maximum length available for a steel angle based on the desired specifications.

- Q: How do you handle and install steel angles on a construction site?

- To handle and install steel angles on a construction site, it is important to follow a systematic process. First, ensure that all necessary safety precautions, such as wearing appropriate protective gear, are in place. Then, use appropriate lifting equipment, such as cranes or forklifts, to safely transport and position the steel angles at the desired location. Next, accurately measure and mark the positions where the angles will be secured. Use appropriate tools, such as drills or welding equipment, to fasten the angles securely to the structure, following the specifications and guidelines provided by engineers or construction plans. Finally, inspect the installation to ensure proper alignment, stability, and structural integrity.

- Q: What are the different types of corrosion that can affect steel angles?

- Steel angles can be affected by various types of corrosion, including: 1. Uniform corrosion: This common type of corrosion evenly deteriorates the entire surface of the steel angle. It usually occurs due to exposure to moisture and oxygen in the surrounding environment. 2. Pitting corrosion: Characterized by the formation of small pits or holes on the steel angle's surface, this type of corrosion happens when localized areas of the metal come into contact with more aggressive corrosive agents, such as chloride ions or acidic substances. 3. Galvanic corrosion: When two different metals are exposed to an electrolyte like water or saltwater, galvanic corrosion takes place. In this process, the more active metal (anode) corrodes while the less active metal (cathode) remains protected. 4. Crevice corrosion: Confined spaces or crevices where stagnant water or moisture accumulates can lead to crevice corrosion. The lack of oxygen and the concentration of corrosive agents can cause localized corrosion and degradation of the steel angle. 5. Filiform corrosion: This type of corrosion manifests as thread-like filaments on the steel angle's surface. It is typically triggered by the presence of moisture, oxygen, and contaminants like salts or organic compounds. 6. Stress corrosion cracking: Stress corrosion cracking occurs when a combination of tensile stress and a corrosive environment causes cracks to develop in the steel angle. This type of corrosion is particularly dangerous as it can result in sudden and catastrophic failure of the structure. It is important to acknowledge that the severity and probability of each corrosion type can vary depending on factors such as the environment, exposure to corrosive agents, and the quality of the steel angle. Regular inspections, maintenance, and appropriate protective coatings can help mitigate the impact of corrosion on steel angles.

Send your message to us

HIGH QUALITY HOT ROLLED WIRE ROD SAE1008 SAE1018 SAE1006

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords