Carbon Steel Hot Rolled Wire Rod SAE1008 SAE1006 SAE1018

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Carbon Steel Hot Rolled Wire Rod SAE1008 SAE1006 SAE1018 at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Carbon Steel Hot Rolled Wire Rod SAE1008 SAE1006 SAE1018 are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Carbon Steel Hot Rolled Wire Rod SAE1008 SAE1006 SAE1018 are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Specifications of Wire Rod SAE1008B:

Steel Grade: SAE1008B Standard: ASTM, GB

Diameter: 5.5mm, 6.5mm, 7mm,8mm,9mm,10mm,12mm,14mm

Type: Drawn Wire Alloy or Not: Alloy Brand Name: N-RIVER

Technique: Hot Rolled Place of Origin: China Mainland

Chemical Composition:

Please kindly find our chemistry of our material based on SAE1008B as below for your information

Grade | Chemical Composition (%) | |||||

C | Mn | S | P | Si | B | |

SAE1008B | 0.10max | 0.32max | 0.045max | 0.040max | 0.30max | 0.0008min |

Mechanical properties | ||||||

Yield strength(N/mm2) | Tensile strength(N/mm2) | Elongation (%) | ||||

≥195 | 350-380 | ≥32 | ||||

Usage and Applications of Wire Rod SAE1008B:

After hot-rolled the products shaped into coil and delivery as finished product, including round, square, rectangular, hexagonal and so on. Since most of the products are round, it is generally called wire rod. Carbon steel wire rod is widely used in construction and manufacturing. Carbon steel wire rod is mainly used for reinforcement of reinforced concrete and welded structure or reprocessed (roberts , nail, etc.) materials, especially used to produce wire drawing, welding electrode, nails, spring, electronic, precise machinery parts and so on.

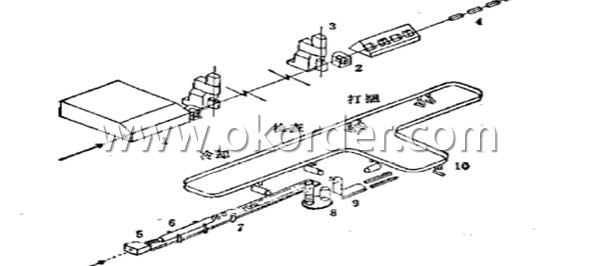

Production Process of Wire Rod SAE1008B:

1-Furnace 2-Roughing Mill 3-High-speed Finishing Mill 4-Water-cooled Device 5-Coiling Device

6-Cooling Device 7-Chain Conveyer 8-Spool Collecting Device 9-Spool Down Device 10-Hook Conveyer

Packaging & Delivery of Wire Rod SAE1008B:

Packaging Detail: products are packed in coil and then shipped by container or bulk vessel

Each coil weight: 2-3MT

Delivery Detail: within 45 days after received deposit or LC.

Label: to be specified by customer, generally, each bundle has 1-2 labels

Trade terms: CFR, CIF

Note:

1. Our products are produced according to national standard (GB), if not, supply according to national standards (GB) or agreement as customer required.

2. Other Grade and Standard carbon steel wire rod we can supply:

Grade: H08A, 30MnSi, 62B-82B

Standard: AISI, BS, JIS, DIN

The Minimum Order Quantity of these products is high, and need to be confirmed.

3. We can not only supply carbon steel wire rod; if you need anything about building materials, please contact us.

4. Please send us your detail specifications when inquire. We will reply to you as soon as possible. We sincerely hope we can establish a long stable business relationship.

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q4: What makes stainless steel stainless?

A4: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Q5: Can stainless steel rust?

A5: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

Images:

- Q: How are steel wire rods used in the manufacturing of bicycle spokes for strength and durability?

- Steel wire rods are used in the manufacturing of bicycle spokes because they provide strength and durability to support the weight and stress exerted on the spokes while riding. The high tensile strength of steel wire rods allows the spokes to withstand heavy loads and resist deformation, ensuring a reliable and long-lasting performance for the bicycle.

- Q: What are the different surface defects that can impact the corrosion resistance of steel wire rod?

- There are several surface defects that can impact the corrosion resistance of steel wire rod. These include pitting, scaling, scratches, cracks, and impurities. Pitting refers to small holes or depressions on the surface, which can create localized corrosion. Scaling is the formation of a rough, flaky layer on the surface due to oxidation. Scratches can provide crevices for corrosion to initiate and propagate. Cracks can compromise the integrity of the wire rod and allow corrosive agents to penetrate. Impurities, such as inclusions or foreign particles, can accelerate corrosion by creating galvanic cells or acting as initiation sites for corrosion. Overall, these surface defects can significantly reduce the corrosion resistance of steel wire rod.

- Q: How does the diameter of steel wire rod affect its strength?

- The diameter of a steel wire rod directly affects its strength. Generally, a larger diameter wire rod will have higher strength compared to a smaller diameter wire rod. This is because a larger diameter rod has a greater cross-sectional area, allowing it to withstand higher loads and stresses without breaking or deforming.

- Q: What are the different types of wire drawing dies used for steel wire rod?

- There are several types of wire drawing dies that are commonly used for steel wire rod. These include: 1. Single crystal natural diamond dies: These dies are made from a single crystal diamond and are known for their high hardness and wear resistance. They can be used for drawing high carbon steel wire rod as well as stainless steel wire rod. 2. Polycrystalline diamond (PCD) dies: PCD dies are made from multiple small diamond crystals that are bonded together. They offer good wear resistance and can be used for drawing steel wire rod with intermediate carbon content. 3. Tungsten carbide dies: Tungsten carbide is a hard and durable material that is often used for wire drawing dies. These dies can handle high carbon steel wire rod and are known for their ability to withstand high pressures and temperatures. 4. Natural diamond dies with carbide support: These dies have a natural diamond core with a carbide support structure. The diamond provides excellent wear resistance while the carbide support adds strength and stability. They are suitable for drawing steel wire rod with high carbon content. 5. PCD dies with carbide support: Similar to the above, these dies have a PCD core with a carbide support structure. They offer good wear resistance and can handle steel wire rod with intermediate carbon content. 6. Polycrystalline diamond composite (PDC) dies: PDC dies are made by sintering diamond particles with a binder material. They are known for their high wear resistance and are often used for drawing steel wire rod with low to medium carbon content. Each type of wire drawing die has its own advantages and is suitable for specific applications based on the carbon content and other properties of the steel wire rod being drawn.

- Q: How does the fatigue strength of steel wire rod vary with different diameters?

- Steel wire rod fatigue strength typically varies depending on its diameter. Generally, an increase in diameter leads to a decrease in fatigue strength. This occurs because larger diameter rods have a greater likelihood of containing defects or imperfections, such as inclusions or microstructural irregularities. These flaws act as stress concentrators, reducing the fatigue strength. Furthermore, larger diameter rods have a larger surface area, increasing the chances of surface defects or corrosion. These factors can negatively impact the fatigue strength. Additionally, larger diameter rods have lower bending stiffness, resulting in higher stresses and strains under cyclic loading, further reducing fatigue strength. Conversely, smaller diameter steel wire rods tend to have higher fatigue strength due to their reduced surface area and fewer chances of defects. Smaller diameter rods also have higher bending stiffness, which helps distribute the applied load more evenly, reducing localized stress concentrations and improving fatigue strength. However, it is important to note that other factors can influence the fatigue strength of steel wire rods, such as the specific type and quality of the steel, the manufacturing process, and the surface treatment. Therefore, when evaluating fatigue strength, it is necessary to consider these factors in addition to the diameter.

- Q: What are the different surface inspection methods for steel wire rod?

- There are several different surface inspection methods that can be used for steel wire rod. These methods are employed to ensure the quality and integrity of the surface of the wire rod. 1. Visual Inspection: This is the simplest and most basic method of surface inspection. It involves visually inspecting the surface of the wire rod for any visible defects such as scratches, dents, or corrosion. 2. Magnetic Particle Inspection: This method involves applying a magnetic field to the wire rod and then applying a magnetic particle solution on the surface. Any defects or cracks in the surface will cause the particles to cluster and become visible under UV light. 3. Eddy Current Testing: This non-destructive testing method involves inducing an electric current in the wire rod and measuring the resulting electromagnetic field. Any variations or anomalies in the electromagnetic field can indicate surface defects. 4. Ultrasonic Testing: This method uses high-frequency sound waves to penetrate the surface of the wire rod. The sound waves are reflected back when they encounter any surface defects or cracks, allowing for their detection. 5. Dye Penetrant Inspection: This method involves applying a liquid dye to the surface of the wire rod. The dye is then allowed to seep into any surface defects or cracks. After a certain period of time, the excess dye is removed, and a developer is applied to make the defects visible. 6. Laser Scanning: This advanced method utilizes laser technology to scan the surface of the wire rod. The laser detects any deviations from the normal surface profile, such as dents or scratches, and provides a detailed analysis of the surface condition. 7. X-ray Inspection: This method is used to inspect the internal and external surface of the wire rod. X-rays are passed through the wire rod, and any defects or anomalies are detected by the variations in the intensity of the X-ray beam. Each of these surface inspection methods has its own advantages and limitations. The choice of method depends on the specific requirements, the type of defects to be detected, and the level of accuracy needed for the inspection.

- Q: How is the cleanliness of steel wire rod assessed?

- Various methods and techniques are utilized to evaluate the cleanliness of steel wire rod, ensuring adherence to high-quality standards. One primary approach involves visual inspection, whereby well-trained personnel meticulously examine the wire rod's surface for visible defects such as scale, cracks, pits, or any other surface irregularities that may compromise its cleanliness. Another technique employed is magnetic particle testing, wherein the wire rod is placed within a magnetic field, and magnetic particles are applied to its surface. Any discontinuities or flaws in the material will attract and accumulate these particles, rendering them discernible under suitable lighting conditions. The assessment of steel wire rod cleanliness also involves the utilization of ultrasonic testing. This non-destructive testing method employs high-frequency sound waves to detect internal defects such as inclusions, voids, or other imperfections that may not be visually evident. Ultrasonic waves are propagated through the wire rod, and any alterations or reflections in the wave patterns can indicate the presence of defects. Chemical analysis represents another pivotal aspect of cleanliness assessment. Samples of the wire rod are extracted and subjected to chemical tests to determine their composition and impurity levels. This analysis enables the identification of contaminants like sulfur, phosphorus, or other elements that could impact the steel's cleanliness. In summary, a combination of visual inspection, magnetic particle testing, ultrasonic testing, and chemical analysis is typically employed to assess the cleanliness of steel wire rod. By implementing these methodologies, manufacturers can guarantee that the wire rod meets the requisite cleanliness standards, thereby ensuring its suitability for diverse applications.

- Q: What are the different types of steel wire rod annealing atmospheres?

- The different types of steel wire rod annealing atmospheres include hydrogen, nitrogen, and endothermic gas.

- Q: What are the standard dimensional accuracy requirements for steel wire rod?

- The dimensional accuracy requirements for steel wire rod vary depending on its specific application and industry standards. However, there are generally accepted tolerances that are adhered to during the manufacturing and production process. In terms of diameter, the dimensional accuracy requirement typically falls within a certain tolerance limit. For instance, a particular grade of steel wire rod may require the diameter to be within +/- 0.10 mm, allowing for a deviation of up to 0.10 mm from the specified value. This tolerance ensures consistency in size and enables proper fit and function in different applications. Likewise, for the length of the steel wire rod, a dimensional accuracy requirement is set to ensure uniformity and compatibility. The length tolerance may be specified as +/- a certain value, such as +/- 0.5% of the specified length. This tolerance ensures that the wire rod meets the desired length requirements and can be easily incorporated into various manufacturing processes. Furthermore, other dimensional parameters like straightness, surface finish, and ovality may also have specific requirements depending on the intended use of the steel wire rod. These requirements ensure efficient processing, forming, and utilization of the wire rod in different applications, while maintaining the desired quality and performance. It is important to highlight that the precise dimensional accuracy requirements for steel wire rod may vary depending on industry standards, customer specifications, and the intended application. Therefore, it is crucial to consult the relevant standards or communicate with the appropriate stakeholders to determine the exact dimensional accuracy requirements for a specific steel wire rod.

- Q: How is steel wire rod used in the construction of bridges and buildings?

- Due to its exceptional tensile strength and durability, steel wire rod is a common choice for constructing bridges and buildings. It serves as a reinforcement material, contributing to the creation of robust and structurally sound structures. Bridges often incorporate steel wire rod in the form of reinforced concrete. By embedding the steel wire rod within the concrete, it provides the necessary tensile strength to withstand heavy loads and prevent cracking or collapsing when under stress. This reinforcement is vital in ensuring the longevity and stability of the bridge, particularly in areas with high traffic or seismic activity. Similarly, buildings utilize steel wire rod in reinforced concrete columns, beams, and slabs. These components play a crucial role in supporting the weight of the building and distributing it evenly throughout the structure. By reinforcing these elements with steel wire rod, the building gains the strength and flexibility required to bear various loads, including live loads (such as furniture and people) and dead loads (such as the weight of the structure itself). Moreover, steel wire rod finds application in pre-stressed concrete techniques. This involves tensioning the steel wire rod before pouring the concrete, resulting in compression within the concrete. This compression counteracts the potential tensile forces that the structure may encounter, thereby improving its overall strength and minimizing the risk of cracking or deformation. In summary, the utilization of steel wire rod enhances the structural integrity, load-bearing capacity, and resistance to external forces in the construction of bridges and buildings. Its versatility and strength make it an ideal material for ensuring the safety and durability of these critical infrastructure projects.

Send your message to us

Carbon Steel Hot Rolled Wire Rod SAE1008 SAE1006 SAE1018

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords