High Quality Fiberglass Fabrics - E Glass Fiberglass Fabrics

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000kg kg

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

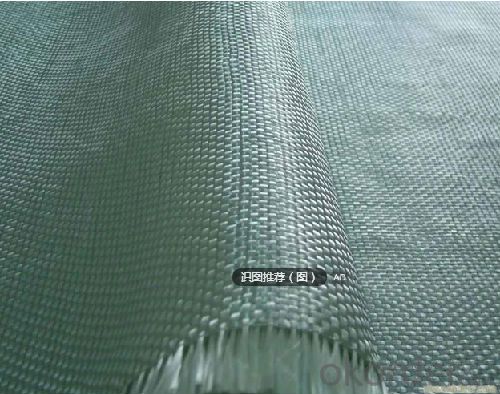

E Glass Fiber Fabrics are bidirectional fabric made by interweaving direct rovings.

E Glass Fiber Fabrics are compatible with unsaturated polyester, vinyl ester, epoxy and phenolic resins.

E Glass Fiber Fabrics are a high performance reinforcement widely used in hand lay up and robot processes to manufacture boats, vessels, plane and automotive parts, furniture and sports facilities.

Product Features:

● Warp and weft rovings aligned in a parallel and flat manner, resulting in uniform tension

● Densely aligned fibers, resulting in high dimensional stability and making handling easy

● Good moldability, fast and complete wet out in resins, resulting in high productivity

● Good mechanical properties and high strength of parts

Product Specifications:

Normal type | EWR800-1000 | Test Standard |

Apperance | Good | GB/T 18370-2001 |

Density(warpxweft)(end/cm) | 1.8 X 1.5 | GB/T 7689.2-2001 |

Tex (warpxweft) | 2400x2400 | ISO1889 |

Moisture content(%) | ≤0.10 | ISO3344 |

Loss on ignition(%) | 0.40-0.80 | ISO1887 |

Glass | E-glass | N/A |

FAQ:

1.What is the delivery time ?

15days after receiving the deposit

2.Are you a trading company or factory.

We are factory,and we have more than 10 years of experience.

- Q: Can fiberglass fabric be used for insulation in industrial ovens?

- Yes, fiberglass fabric can be used for insulation in industrial ovens. Fiberglass fabric has excellent thermal insulation properties and can withstand high temperatures, making it an ideal choice for insulating industrial ovens. It can effectively trap heat, preventing it from escaping the oven, and thus improving energy efficiency. Additionally, fiberglass fabric is durable, resistant to chemical and moisture exposure, and has low thermal conductivity, making it a reliable and long-lasting option for insulation in industrial ovens.

- Q: Can fiberglass fabric be used for making insulation tape?

- Insulation tape can indeed be made using fiberglass fabric. This fabric is renowned for its exceptional thermal insulation capabilities, thanks to its composition of woven glass fibers that can withstand high temperatures. These fabric tapes find widespread application across industries like electrical, automotive, and aerospace, serving to insulate and safeguard wires, cables, and pipes from heat and electrical currents. Typically, the fiberglass fabric is coated with a heat-resistant adhesive, enabling it to stick to different surfaces and establish a reliable insulation barrier. In conclusion, fiberglass fabric proves to be an appropriate option for manufacturing insulation tape due to its resistance to heat, durability, and versatility.

- Q: Is fiberglass fabric resistant to fading?

- Yes, fiberglass fabric is resistant to fading. Fiberglass is a synthetic material made from fine fibers of glass, which are highly resistant to fading caused by exposure to sunlight. These fibers are often coated with a protective layer that further enhances their resistance to fading. Additionally, fiberglass fabric is also resistant to many chemicals and does not easily deteriorate over time, making it a durable and long-lasting option for various applications.

- Q: Can fiberglass fabric be used for air ducts?

- Yes, fiberglass fabric can be used for air ducts. It is a common material used in HVAC systems for its insulation properties and durability. Fiberglass fabric helps to maintain temperature control and prevents air leakage in ductwork, making it suitable for air duct applications.

- Q: Can fiberglass fabric be used for heat-resistant aprons?

- Heat-resistant aprons can indeed be made using fiberglass fabric. Known for its exceptional heat resistance properties, fiberglass fabric is capable of withstanding high temperatures without melting or igniting. It finds extensive usage in industries where employees are exposed to intense heat or flames, like welding, foundries, and glass manufacturing. Due to its durability and effective insulation, fiberglass fabric is an excellent option for heat-resistant aprons. Furthermore, it is lightweight and flexible, ensuring ease of movement and comfort while providing the essential heat protection.

- Q: Is fiberglass fabric resistant to chemicals used in water treatment?

- Fiberglass fabric is generally resistant to the chemicals commonly used in water treatment. It is renowned for its exceptional chemical resistance and is frequently employed in a variety of industries, such as water treatment facilities. It can endure exposure to a vast range of chemicals, including chlorine, acids, alkalis, and other substances commonly utilized in water treatment procedures. This chemical resistance renders fiberglass fabric an ideal choice for applications where it may come into contact with these chemicals, ensuring durability and longevity. However, it is crucial to take into account the specific type and concentration of chemicals employed in water treatment when selecting the appropriate fiberglass fabric, as certain chemicals may necessitate additional protective measures.

- Q: Can fiberglass fabric be used for heat shields?

- Yes, fiberglass fabric can be used for heat shields. Fiberglass is known for its excellent thermal insulation properties, making it an ideal material for heat shields. It can withstand high temperatures without deforming or melting, which is crucial for protecting sensitive equipment or structures from heat damage. Additionally, fiberglass fabric is also lightweight, flexible, and can be easily molded or cut into desired shapes, allowing for easy installation in various applications where heat protection is required.

- Q: Can fiberglass fabrics be used for automotive applications?

- Certainly, automotive applications can indeed make use of fiberglass fabrics. Fiberglass fabrics possess notable characteristics such as high strength-to-weight ratio, durability, and resistance to heat and chemicals. These qualities render them appropriate for a variety of automotive uses like reinforcing body panels, constructing interior components, and creating structural reinforcements. By molding and shaping fiberglass fabrics, specific automotive parts can be easily accommodated, providing both strength and stability while simultaneously reducing weight. Moreover, the thermal insulation properties of fiberglass fabrics make them highly suitable for employment in automotive exhaust systems and engine compartments. All in all, fiberglass fabrics bring forth numerous advantages in terms of performance, durability, and design flexibility, thus proving their suitability for a wide array of automotive applications.

- Q: Difference and characteristics of fluorine glue glass fiber cloth and three yuan ethylene propylene glass fiber cloth

- Fluorine rubber and three yuan ethylene propylene adhesive tape are a new kind of high temperature and corrosion resistant fluorine polymer elastomer, which is a new type of multipurpose composite material coated with glass fiber.

- Q: How do you do fiberglass fabric on latex paint?

- A small area of their own to do the next experiment.

Send your message to us

High Quality Fiberglass Fabrics - E Glass Fiberglass Fabrics

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000kg kg

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords