Fiberglass Mesh Fabric Roll for Construction e-glass Fiberglass Mesh

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

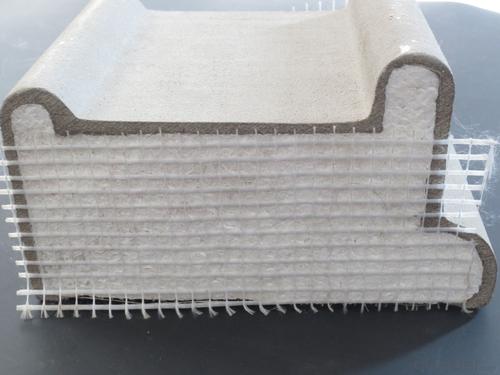

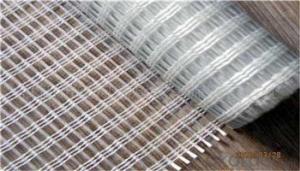

Alkali-resistant wall reinforced Fiberglass Mesh fiberglass manufacturer

Pass CE &ISO 9001

width can be 200cm

Firm mesh

The grid component

Fiberglass mesh is based on glass fiber woven fabric as substrate, the macromolecular

anti emulsion coating. It has good alkali resistance, flexibility and latitude to the high tensile

strength, with its good chemical stability, high strength, light weight, good dimensional

stability, strong impact resistance, pest control, fire protection, thermal insulation and

other features, welcomed by the user .

Use the grid cloth

Its widely used in: 1, wall reinforcing material; 2, reinforced cement products; 3, internal and

external wall insulation, 4, granite, marble, mosaic special mesh back paste network;

5, waterproof cloth, asphalt roofing; 6, reinforcing materials of plastics, rubber products;

7, fire board; 8, the grinding wheel base; 9, highway pavement with geogrid; 10, building

sealing tape etc.

- Q: Two, fat and PVC paste resin paste into the sizing, coated on glass fiber cloth, so that after baking, how do not shrink?

- Do not grind finer, the particles are too small at room temperature, often because of excessive solvent and paste viscosity high.

- Q: Can fiberglass fabrics be used for reinforcement in electronic devices?

- Yes, fiberglass fabrics can be used for reinforcement in electronic devices. Fiberglass fabrics are known for their high strength, durability, and electrical insulation properties, making them suitable for various applications in the electronics industry. These fabrics can be used to reinforce electronic components, such as circuit boards, to improve their mechanical strength and prevent damage from vibrations or impacts. Additionally, the electrical insulation properties of fiberglass fabrics make them ideal for reinforcing cables and wires, protecting them from abrasion and enhancing their overall performance and longevity. Overall, fiberglass fabrics provide an excellent solution for reinforcing electronic devices and components, ensuring their reliability and longevity in various operating conditions.

- Q: What are the different fiberglass fabric coatings for chemical resistance?

- There are several different fiberglass fabric coatings available for chemical resistance, including neoprene, polyurethane, vinyl, and silicone. These coatings provide a protective barrier against a wide range of chemicals, ensuring the durability and longevity of the fiberglass fabric in various applications.

- Q: Is fiberglass fabric resistant to ultraviolet radiation?

- Yes, fiberglass fabric is highly resistant to ultraviolet (UV) radiation. Fiberglass is made from glass fibers that are woven together to create a strong and durable fabric. This fabric is naturally resistant to UV radiation due to the properties of glass, which does not degrade or deteriorate when exposed to sunlight. This makes fiberglass fabric an excellent choice for outdoor applications, such as in the construction of awnings, canopies, and outdoor furniture, where protection against UV rays is essential. Additionally, fiberglass fabric can also be treated with special coatings or finishes that enhance its UV resistance, further increasing its longevity and performance in outdoor environments.

- Q: Asphalt + glass fiber cloth

- General underground pipeline corrosion protection, the past specifications are three oil two cloth

- Q: Can fiberglass fabric be used for making boats?

- Boats can indeed be made using fiberglass fabric. Fiberglass is a popular choice for constructing boats because of its strength, durability, and lightweight qualities. It is commonly used to build the hulls, decks, and other important parts of boats. By layering fiberglass fabric and combining it with resin, a sturdy and rigid composite material is created. This combination offers an excellent strength-to-weight ratio, making it perfect for boat construction. Furthermore, fiberglass is resistant to corrosion, rot, and UV damage, making it suitable for boats that will be exposed to harsh marine environments. All in all, fiberglass fabric is a versatile material that has successfully been used to construct various types of boats, including recreational boats, sailboats, and high-performance racing boats.

- Q: How does fiberglass fabric perform in cryogenic temperatures?

- Fiberglass fabric performs well in cryogenic temperatures as it has excellent thermal insulation properties and maintains its structural integrity even at extremely low temperatures. It is highly resistant to thermal shock and can withstand prolonged exposure to cryogenic environments without significant degradation.

- Q: Is fiberglass fabric resistant to chemicals in mining operations?

- Yes, fiberglass fabric is generally resistant to chemicals in mining operations. It is known for its excellent chemical resistance, making it suitable for use in environments where exposure to various chemicals is common.

- Q: How to deal with thermal cracking of exterior wall?

- Replacement of existing insulation materials and repair of cracks. After cracking, often cause leakage passage. The water insulation layer, thermal insulation performance, such as freeze-thaw damage. At this time, the impact of the scope of the heat preservation material replacement, re construction. Then, if the insulation layer and wall have been cracking, we should use glue, grouting (epoxy resin) and other practices to plug the gap. Insulation materials are loose, and reinforcement measures such as studs. Replacement of insulation materials and large surface materials are often not bonded, encryption reinforcement measures should be taken.

- Q: What is the moisture resistance of fiberglass fabric?

- Fiberglass fabric has high moisture resistance due to its inherent non-absorbent nature and the hydrophobic properties of the fiberglass material.

Send your message to us

Fiberglass Mesh Fabric Roll for Construction e-glass Fiberglass Mesh

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords