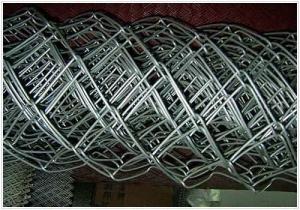

High Quality Chain Link Fence Panel

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Type: | Place of Origin: | Application: | Agriculture field, sport field, tennis | ||

| Model Number: | Frame Material: | Metal Type: | |||

| Pressure Treated Wood Type: | Frame Finishing: | Feature: | |||

| Material: | Surface treatment: | Roll Length: | |||

| Mesh/Opening: | Color: |

Packaging & Delivery

| Packaging Detail: | 1.woven bags of the above and bottom,high quality package or as customes requested 2.In roll ,water proof paper in side and our side with weave bag;carton;wooden case;pallet. 3. according to customers requirement. |

Galvanized Chain Link Fence | |||||

wire diameter mm | mesh size mm | roll length m | standard netting heights mm | standard post heights mm | |

1 | 5×5 | 10 | 500 | 1000 | |

1000 | 1500 | ||||

1.2 | 10×10 | 10 | 1250 | 2000 | |

20×20 | 1500 | 2000 | |||

1.4 | 20×20 | 10 | 2000 | 2500 | |

1.8 | 30×30 | 10 | 2500 | 3000 | |

2.5 | 40×40 | 10 | 3000 | 3500 | |

2.8 | 50×50 | 10 | 4000 | 4500 | |

3 | 50×50 | 10 | 5000 | 5500 | |

4 | 60×60 | 10 | 5000 | 5500 | |

|

|

|

|

| |

PVC Coated Chain Link Fence | |||||

Wire diameter mm | mesh size mm | roll length m | standard netting heights mm | standard post heights mm | |

1.8 | 20×20 | 10 | 500 | 1000 | |

1000 | 1500 | ||||

1250 | 2000 | ||||

1500 | 2000 | ||||

1.8 | 30×30 | 10 | 2000 | 2500 | |

2.5 | 40×40 | 10 | 2500 | 3000 | |

2.8 | 50×50 | 10 | 3000 | 3500 | |

3 | 60×60 | 10 | 4000 | 4500 | |

4.5 | 65×65 | 10 | 5000 | 5500 | |

- Q: How is steel wire mesh used in the textile industry?

- Steel wire mesh is commonly used in the textile industry for various applications. One of the main uses of steel wire mesh in this industry is as a support structure for fabric during the printing process. When fabric is being printed, it needs to be stretched tightly to ensure accurate and consistent printing results. Steel wire mesh, with its high tensile strength, provides the necessary support and stability to the fabric, allowing for precise and detailed printing. Additionally, steel wire mesh is used in the textile industry for fabric reinforcement. Fabrics that require extra strength and durability, such as those used in industrial applications or heavy-duty clothing, can be reinforced with steel wire mesh. By integrating the mesh into the fabric structure, it increases the overall strength and resistance to tearing or stretching, making the fabric suitable for demanding applications. Another way steel wire mesh is used in the textile industry is for filtration purposes. In textile manufacturing processes, there are often impurities or particles that need to be removed from the liquid or gas used. Steel wire mesh, with its fine and uniform openings, can act as an effective filter, allowing the liquid or gas to pass through while trapping the unwanted particles. This helps to ensure the quality and cleanliness of the textile materials being produced. Furthermore, steel wire mesh is also utilized as a protective barrier in the textile industry. It can be used to create enclosures or fencing to prevent access to sensitive areas or to safeguard machinery and equipment. This helps to enhance safety in the workplace and protect valuable assets from damage or theft. In summary, steel wire mesh plays a vital role in the textile industry. It is used as a support structure during the printing process, for fabric reinforcement, as a filtration medium, and for creating protective barriers. Its strength, durability, and versatility make it an essential component in various textile applications, contributing to the overall quality and functionality of textile products.

- Q: Can steel wire mesh be used for noise reduction?

- In certain applications, steel wire mesh proves to be effective in reducing noise. Acting as a barrier, the mesh aids in blocking or absorbing sound waves, thus diminishing the amount of noise that can pass through. This makes it a viable option for managing noise in diverse environments, such as industrial facilities, construction sites, or even residential areas near highways or airports. Steel wire mesh can be utilized as a stand-alone barrier or in conjunction with other noise reduction materials, including acoustic panels or insulation. The arrangement and thickness of the mesh depend on the desired level of noise reduction and the frequency range of the targeted sound. It is important to note that while steel wire mesh can effectively reduce noise, it may not entirely eliminate all sounds. Its effectiveness is influenced by factors such as wire thickness and density, mesh opening size, and installation method. Moreover, the overall effectiveness may vary based on the specific noise source and the surrounding environment. In summary, steel wire mesh serves as a valuable tool in minimizing noise levels in various situations. However, it is advisable to seek guidance from a professional or an acoustic engineer to determine the most suitable solution for your specific noise reduction requirements.

- Q: What is the maximum width of steel wire mesh available?

- The maximum width of steel wire mesh available can vary depending on the specific manufacturer and their capabilities. However, it is common to find steel wire mesh with widths ranging from 4 to 8 feet.

- Q: How is steel wire mesh used in reinforcement of slabs?

- Steel wire mesh is commonly used in the reinforcement of slabs to enhance their strength and durability. It is placed within the concrete mixture to provide additional support and prevent cracking. The mesh helps distribute the load evenly across the slab, reducing the risk of structural failure and improving its overall performance.

- Q: Can steel wire mesh be used for safety barriers?

- Yes, steel wire mesh can be used for safety barriers. Steel wire mesh is a durable and sturdy material that can effectively provide protection and enhance safety in various applications such as construction sites, highways, and industrial areas. It can be easily installed and offers visibility while preventing unauthorized access or potential hazards.

- Q: Can steel wire mesh be bent?

- Yes, steel wire mesh can be bent.

- Q: What are the different wire materials used in steel wire mesh?

- Some of the different wire materials used in steel wire mesh include carbon steel, stainless steel, galvanized steel, and aluminum.

- Q: How does the coating affect the resistance of steel wire mesh to chemicals?

- The coating on steel wire mesh acts as a protective barrier that can significantly enhance its resistance to chemicals. It prevents direct contact between the chemicals and the steel, reducing the risk of corrosion and degradation. The type and quality of the coating can determine its effectiveness against various chemicals, as some coatings are specifically designed to resist certain substances. Overall, a well-applied and durable coating can greatly improve the resistance of steel wire mesh to chemicals, allowing it to withstand harsh environments and prolong its lifespan.

- Q: Is steel wire mesh fire-resistant?

- Generally, steel wire mesh is acknowledged as being fire-resistant. The reason for this is that steel possesses a high melting point and does not easily ignite or combust. Steel wire mesh is widely utilized in various contexts that necessitate fire resistance, such as in construction, industrial environments, and fencing. It is capable of enduring high temperatures and is frequently employed as a protective barricade to hinder the propagation of fire or to confine flames. Nevertheless, it is crucial to take into consideration that the extent of fire resistance may differ depending on the specific kind and thickness of the steel wire mesh. It is always advisable to consult manufacturers or experts in the industry to ensure that the steel wire mesh satisfies the required fire resistance standards for a specific application.

- Q: What are the benefits of using steel wire mesh in the oil and gas industry?

- There are several benefits of using steel wire mesh in the oil and gas industry. Firstly, steel wire mesh offers high strength and durability, making it suitable for withstanding the harsh conditions and extreme temperatures typically found in oil and gas operations. Additionally, the mesh provides excellent corrosion resistance, ensuring a longer lifespan and reducing the need for frequent replacements. Steel wire mesh also offers excellent filtration capabilities, allowing for the removal of impurities and contaminants from fluids and gases, thus maintaining the quality and efficiency of the processes. Moreover, the mesh can be easily fabricated into various shapes and sizes, providing flexibility in design and installation. Overall, the use of steel wire mesh in the oil and gas industry enhances safety, efficiency, and cost-effectiveness in operations.

Send your message to us

High Quality Chain Link Fence Panel

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords