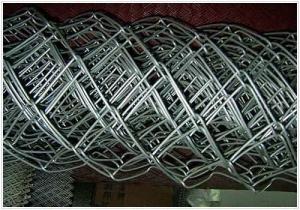

Good Quality Chain Link Fence

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Material: The low carbon steel , elec-galvanized steel wire, hot-dip galvanized steel wire, pvc coated wire, stainless steel wire etc.

Surface treatment: Elec-galvanized, hot-dip galvanized, pvc coated, powder coating etc.

Feature: The structure of this kind of wire mesh is strong, lasting and rust-resistant.Galvanized welded wire mesh is galvanized after welding.

Application: They are used in industry and agriculture building, transportation and mining for all such purposes as poultry houses, egg baskets, runway enclosures, draining rack, fruit drying screen, fence.

Welded wire mesh divides into stainless steel, hot dipped galvanized and electro galvanized.The adoption plates the zinc craft after welding,it is made from high-quality iron wire by automatic equipment .

The products have smooth mesh surface ,well-proportioned meshes ,strong welded points and bright luster.The mesh does not come loose even if cut in parts or being exerted force on parts .Compared with general iron wire,the products are better in respects of anti-corrosive and anti rust.

Welded Wire Mesh Use:used in the industry ,agriculture ,construction,transport and mining .Such as machine protection cover ,ranch fender ,garden fender ,window protection fender ,passage fender ,fowl cage ,egg basket and foodstuffs basket.

surface treated:Galvanized and PVC coated,stainless steel wire

Weaving and characteristics:

Hot dipped galvanizing after weaving

Weaving with hot dipped galvanized iron wireElectric galvanizing after weaving

Weaving with electric galvanized iron wirePVC coated welded wire mesh

- Q: How is steel wire mesh used in the energy industry?

- Steel wire mesh is widely used in the energy industry for a variety of applications. One prominent use of steel wire mesh in this sector is for filtration purposes. In oil and gas production, steel wire mesh filters are utilized to separate impurities and solid particles from fluids, ensuring the smooth operation of pipelines and machinery. These filters prevent clogging and damage to equipment, which ultimately helps to maintain the efficiency and reliability of energy production processes. Steel wire mesh is also commonly employed in power generation plants, particularly in boilers and condensers. These mesh screens are used to separate and retain solid particles, preventing them from entering turbines and other sensitive components. By doing so, steel wire mesh helps to enhance the efficiency and longevity of power generation equipment, reducing maintenance costs and downtime. Another important application of steel wire mesh in the energy industry is in the construction and reinforcement of structures. For instance, steel wire mesh is often embedded in concrete to provide additional strength and prevent cracking. This is particularly crucial in the construction of power transmission towers and substations, where the mesh acts as a reinforcement to withstand wind, seismic activity, and other external forces. Moreover, steel wire mesh is utilized in the energy industry for safety purposes. It is commonly used as a protective barrier around electrical equipment, transformers, and high-voltage areas to prevent accidental contact and mitigate the risk of electric shock. Additionally, steel wire mesh can be used as fencing around energy facilities to enhance security and restrict unauthorized access. In summary, steel wire mesh plays a vital role in the energy industry. Whether it is used for filtration, reinforcement, or safety purposes, its strength, durability, and versatility make it an indispensable material for various applications in this sector.

- Q: Can steel wire mesh be used as a safety barrier?

- Yes, steel wire mesh can be used as a safety barrier. Steel wire mesh is a versatile material that can provide effective protection in various applications. It is commonly used as a safety barrier in construction sites, industrial areas, and public spaces. The strength and durability of steel wire mesh make it an ideal choice for containing and preventing access to hazardous areas. It can effectively prevent unauthorized entry, control traffic, and protect people and property from potential dangers. Additionally, steel wire mesh is resistant to corrosion and can withstand harsh weather conditions, ensuring long-lasting performance as a safety barrier. Overall, steel wire mesh is a reliable and cost-effective solution for creating a secure and safe environment.

- Q: How flexible is steel wire mesh?

- Steel wire mesh is highly flexible due to the inherent properties of steel. It can be easily bent, twisted, or molded into various shapes without losing its strength or structural integrity.

- Q: How does steel wire mesh perform in terms of resistance to chemical exposure?

- Steel wire mesh generally demonstrates good resistance to chemical exposure. The material of steel is inherently durable and has a high resistance to corrosion, making it suitable for various industrial and commercial applications. When exposed to chemicals, steel wire mesh typically maintains its structural integrity and does not easily degrade or weaken. However, the exact performance of steel wire mesh in chemical environments can depend on the specific type of chemical, concentration, temperature, and duration of exposure. In some highly corrosive or aggressive chemical environments, additional protective coatings or materials may be required to enhance the resistance of steel wire mesh. It is important to consult with manufacturers or experts to determine the specific compatibility of steel wire mesh with different chemicals and to ensure that the appropriate materials are selected for the specific application.

- Q: What are the different spacing options available for steel wire mesh?

- The different spacing options available for steel wire mesh include various patterns such as square mesh, rectangular mesh, and diamond mesh. The spacing options can vary from tight configurations with small openings to larger openings for increased visibility and airflow.

- Q: Can steel wire mesh be used for creating decorative ceilings or screens?

- Yes, steel wire mesh can definitely be used for creating decorative ceilings or screens. Steel wire mesh is a versatile material that can be easily manipulated and shaped into various designs and patterns. It can be used to create visually appealing and unique ceilings or screens that add a modern and contemporary touch to any space. One of the advantages of using steel wire mesh for decorative purposes is its durability. Steel wire mesh is strong and resistant to wear, making it suitable for long-lasting installations. It can withstand different environmental conditions and is not easily affected by moisture or temperature changes. Furthermore, steel wire mesh offers a wide range of design possibilities. It can be woven or knitted into different patterns, allowing for the creation of intricate and eye-catching designs. Additionally, different wire thicknesses and coatings can be applied to achieve specific aesthetic effects, such as increased transparency or color variations. Steel wire mesh is also a popular choice for creating screens or dividers within a space. It can be used to partition areas while maintaining an open and airy feel. The transparency of the mesh allows for the passage of light and air, creating a sense of openness and connectivity. In summary, steel wire mesh is an excellent choice for creating decorative ceilings or screens. Its durability, versatility, and aesthetic possibilities make it a popular material for architects, designers, and homeowners looking to add a modern and unique touch to their spaces.

- Q: Can steel wire mesh be used for storage racks?

- Yes, steel wire mesh can be used for storage racks. It provides a sturdy and durable structure that allows for proper storage and organization of various items. The mesh design also allows for visibility and ventilation, making it suitable for storing items in warehouses, retail spaces, or even at home.

- Q: How does the material finish affect the appearance of steel wire mesh?

- The material finish plays a significant role in determining the appearance of steel wire mesh. The finish can affect various aspects such as color, texture, and overall aesthetics. One of the primary ways the material finish affects the appearance is through color. Different finishes can result in various colors, from the natural metallic silver of bare steel to a wide range of options like black, white, or other custom colors. This allows for customization to match specific design preferences or blend in with surrounding elements. The finish also influences the texture of the steel wire mesh. For instance, a galvanized finish creates a smooth and shiny surface, while a powder-coated finish can provide a matte or textured appearance. These variations in texture can add depth and visual interest to the mesh, making it more visually appealing. Moreover, the material finish can impact the overall aesthetics of the steel wire mesh. A polished or reflective finish can give the mesh a modern and sleek look, perfect for contemporary designs. Conversely, a rustic or aged finish can provide a more vintage or industrial appearance, suitable for traditional or rugged applications. Additionally, the material finish can affect the durability and longevity of the steel wire mesh. Certain finishes, such as galvanizing or powder coating, provide protection against corrosion and other environmental factors, ensuring the mesh retains its appearance over time. In conclusion, the material finish of steel wire mesh has a significant impact on its appearance. It determines the color, texture, and overall aesthetics, allowing for customization and enhancing the visual appeal. The choice of material finish also influences the durability and longevity of the mesh, ensuring it maintains its appearance for an extended period.

- Q: Can steel wire mesh be used for creating sunscreens or shades?

- Yes, steel wire mesh can be used for creating sunscreens or shades. It provides durability and strength, making it suitable for outdoor applications. Additionally, the mesh design allows for effective airflow while blocking out sunlight, making it an ideal material for sun protection.

- Q: How is steel wire mesh used in industrial settings?

- Steel wire mesh has a wide array of uses in various industrial settings. Filtration processes primarily depend on steel wire mesh as it acts as a filter medium to separate particles and contaminants from liquids and gases. By acting as a barrier, the mesh allows fluid to pass through while trapping unwanted debris, ensuring a cleaner and purer end product. Reinforcement and construction also heavily rely on steel wire mesh. It is extensively used to strengthen concrete structures like roads, bridges, and buildings. The mesh provides added strength and structural integrity, preventing cracks and enhancing durability. Moreover, it evenly distributes the load, minimizing the risk of structural failure. In terms of security, steel wire mesh is frequently employed in industrial settings. It is commonly utilized to create fences and enclosures, effectively restricting access to specific areas and safeguarding personnel and assets. The mesh's strength and rigidity make it an excellent barrier against unauthorized entry, vandalism, and theft. Material handling, sorting, and sieving operations in industrial manufacturing processes also make use of steel wire mesh. It is frequently used as conveyor belts or screens to transport or separate materials based on their size, shape, or composition. With the ability to withstand heavy loads, high temperatures, and harsh environments, steel wire mesh finds applications in various industries, including mining, food processing, and recycling. Additionally, steel wire mesh is employed for ventilation and heat dissipation purposes in industrial settings. It is commonly utilized as ventilation panels or screens, allowing the free flow of air while keeping unwanted objects out. This helps maintain optimal air quality, temperature, and humidity levels within industrial spaces, creating a healthier and more comfortable working environment. In conclusion, the versatility, strength, and durability of steel wire mesh make it an essential component in industrial settings. Its applications span from filtration and reinforcement to security, material handling, and ventilation. Consequently, steel wire mesh significantly contributes to improved efficiency, safety, and productivity across numerous industries.

Send your message to us

Good Quality Chain Link Fence

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords