High Quality AR Glass Fiber Chopped Strand- Zirconia 16.5%

- Loading Port:

- Shanghai Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1000Kgs m.t.

- Supply Capability:

- 100000 Tons Per Year m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of AR Glass Fiber Chopped Strand- Zirconia 16.5%:

AR glassfiber is one kind of concrete fiber used for spary up or mechanical continuous formed GRC, such as formwork roof board, decoration panel, garden feature. It has widely used in tunnel, mine shaft, protect slop, spray-up roving for reinforcement surface and tip of wall.

Technical Data of AR Glass Fiber Chopped Strand- Zirconia 16.5%:

PRODUCT NAME | AR- FIBERGLASS CHOPPED STRAND | |||

TEST CRITERION | JC/T572-2002 | |||

TEST ITEM | METERAGE UNIT | STANDARD | RESULT | CONCLUSION |

ZRO2CONTENT | % | ≥16.5 | 16.7 | MEASURE UP |

MOISTURE CONTENT | % | ≤0.2 | 0.1 | MEASURE UP |

TENSILEBREAKING STRENGTH | N/TEX | ≥0.25 | 0.3 | MEASURE UP |

CHOPPED LENGTH | MM | 12±1 | 12 | MEASURE UP |

LINEAR DENSITY | TEX | 98±8 | 99 | MEASURE UP |

COMBUSTIBLE MATTER CONTENT | % | 0.8-2.0 | 1.48 | MEASURE UP |

CONCLUSION | IN CONPLIANCE WITH JC/T572-2002 | |||

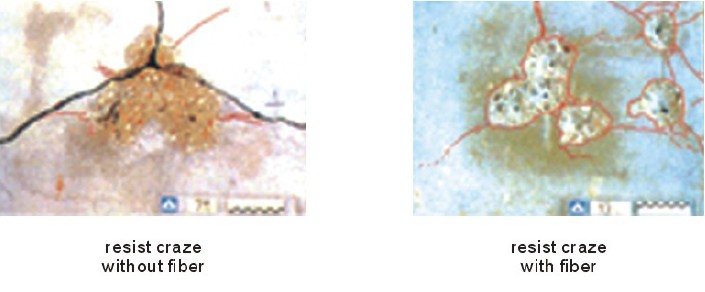

Crack Test:

- Q: What color is the cement they use to put a permanent crown on. When I was flossing the other day this hard white stuff came out from between my teeth where the crown is. Could that be cement, should I be worried? That tooth had a root canal and a crown and the crown is sensitive when I eat hard foods on it.

- Don't worry it's just the cement.Sometimes it gets on the gum line and it's just flaking off.Don't chew hard things on the side that you got your crown on.It takes some time for your gumline to adjust to the crown.

- Q: I spoke to a tile guy recently and he told me that only cement board is acceptable for use in bathrooms. He said that green board is not. Why do the sell the greenboard if you cannot use it in bathrooms or areas that will take moisture?

- Greenboard is moisture and mildew RESISTANT not proof. Many local buildings have banned the use of greenboard in high moisture areas due to the fact that they can and many times do break down in time (average 10 years) Cementboard, wire lath and plaster are much better and more permanent solutions. Good Luck

- Q: rubber cement or liquid glue? which one would work better for making a homade card. ill be glueing on small pieces of paper and ribbon to a larger sheet of paper

- Gorilla Glue is just right, but weight it down at the same time it dries. GG expands something like 30% and makes air bubbles when drying, so if it can be no longer weighted, the rubber piece will stick up and may ooze. Use sparingly!

- Q: In a CSI episode, a guy filled his letter box with cement because his letter box was getting destroyed every night. He had 4 destroyed, had enough and decided to fill the next one with cement. What happened was two guys drove past with a bat, the guy swung to hit the letter box but because it went wrong they crashed and died. The owner buried the letter box, replaced it but of course the CSI team figured it out...and he was arrested. What was the crime he committed? I mean, he had to pay for the replacements so why is he being punished for trying to protect his property? He didn't mean the boys any harm, he was just trying to save his letterbox...

- Cement Mailbox

- Q: On the gas tank of my motorcycles is edged rubber and edged thin steel. The edged rubber slides into the edge of the steel. Some of the rubber has come off the edge of the steel, and I was wondering how could I glue it. I thought of rubber cement, but I don't know. Also should I prime the steel by taking some light sandpaper to it? Thanks.

- For that application I recommend using contact cement. With a pencil, trace around the pad locations onto the gas tank. Apply contact cement carefully, within the lines on the gas tank. If the tank has been painted, lightly sand it (within the area to be glued) to make the area dull so it will accept the cement more readily. When this has been done, and the correct amount of time has passed, carefully position the pads on to the tank.

- Q: I want to do building business business sand cement stones. The (Need to add) What equipment needs to invest about how many predecessors advice about how business can do well.

- Forklift 50 good application, and now the transport equipment are relatively large, first of all better equipment ah. Excavators, venues, inventory, working capital, at least 100 million.

- Q: how many bags of portland cement do I need to build a slap of 40m by 30 m by 10cm?

- the concrete volume is = 40 x 30 x 0.10 = 120 m^3 of concrete each cubic meter of concrete require 6 bags of cement then total cement bags = 6 x 120 = 720 bags

- Q: Are there any paper cement that has no harmful odors ?Are odors or vapors from paper cement considered harmful ?

- can not understand your question

- Q: hi i know how cement is made. my main question is when do we use cement entirely? for instance, concrete is used to make roads etc. similarly, in constructing a 10 floor building, do we concrete in all the 10 floors or is concrete used only in foundation and pilings/pillars etc? is cement used only as a smoothing agent or as binding agent in making brick walls etc.thx

- you use concreted to cover a person in.. You use cement to make shoes for a person out of tide boxes then you throw them in the water...

- Q: Due to rising prices of building materials, which affected the progress of the project, need to make a report, such as how to write, and make a note, for example: cement prices nearly doubled

- As long as your ideas are correct, you can write it For reference only: XXXX Construction unit: According to the construction contract XX Article XX, cement unit price is now XXX yuan per ton, has exceeded the scope of the contract Please consider your unit practical difficulties, please give compensation for cement prices beyond the part of the cost Construction unit: XXX date

1. Manufacturer Overview

| Location | Shanxi, China |

| Year Established | 1982 |

| Annual Output Value | Above US$ 30 Million |

| Main Markets | 20.00% North America 20.00% South America 10.00% Eastern Europe 10.00% Southeast Asia 10.00% Northern Europe 10.00% South Asia 10.00% Western Europe 5.00% Africa 5.00% Mid East |

| Company Certifications | ISO9001:2000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai Port, China |

| Export Percentage | 41-50% |

| No.of Employees in Trade Department | 20-30 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 50,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Design Service Offered; Buyer Label Offered |

| Product Price Range | High; Average |

Send your message to us

High Quality AR Glass Fiber Chopped Strand- Zirconia 16.5%

- Loading Port:

- Shanghai Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1000Kgs m.t.

- Supply Capability:

- 100000 Tons Per Year m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords