High Quality Aluminum Profiles Sliding Screen Door Wafer with a Good Price

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

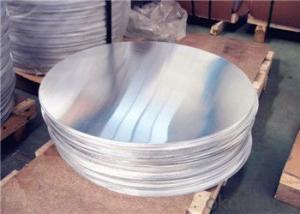

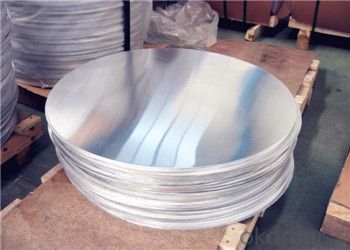

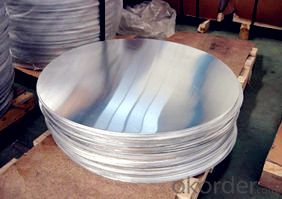

Aluminum Wafer

Aluminum Wafer Description

Aluminum wafers are widely used in electronics, cosmetic, medicine, culture and education and auto parts. Electrical appliances,heat preservation,machinery manufacturing,automotive, aerospace,military, mold,construction,printing and other industries. Such as kitchen utensils such as non-stick pan,pressure cookers and other hardware supplies such as shades,water heaters shell,is the largest amount of aluminum alloy strip deep processing of one of the products.

Aluminum Wafer Production Methods

Punch processing

1. Rough material cut (cut into a square)

2. Blank (punching into the Aluminum discs you want)

If it is a roll material, it is necessary to open the material.

Aluminum Wafer Alloy state

Main series: 1 series, 3 series, 5 series, 6 series, 8 series is in the majority.

State : O, H ;

Aluminum Wafer Packaging

Technical Features of Aluminum Wafers Production Line

1. NC automatic, the production line from the coil from the volume, until the whole roll material to complete the middle of the material does not require manual contact with any material, do not need any adjustment, fundamentally put an end to the ordinary punch punch production safety risks and Product quality hidden.

2. The line can use the coil directly to the wafer production, do not need to roll the material slitting and cross-cutting treatment, reducing the production process, reducing the cost of production and reduce the damage to the surface of the material may be produced Wafer to ensure that no oil, no scratches.

3. The line full use of the width of the coil, the use of high-precision servo motor drive system control, so that the wafer spacing and wafer to the material edge of the distance to a minimum, fundamentally reduce the amount of waste, raw material utilization rate of 80% the above.

4. The production rate can reach 40-55 per minute, to improve the production efficiency.

5.Due to the use of modular mold design, when the conversion of wafer production specifications, the conversion time can be reduced to 15 minutes or less. The diameter of the wafer that can be produced ranges from 85 mm to 750 mm.

6. Advanced open system, six heavy leveling machine, high rigidity of the mechanical presses, automatic palletizing system, to ensure that the wafer products of high quality.

Introduction of our company

Our company is one of the largest aluminum cookware producer in China, and we have produced aluminium circles over 20years, our aluminum circles could be good quality for cookware deep drawing and spinning dawing usage.

Also we are the professional Aluminium Strip manufacturer and Aluminum Circles manufacturers,mainly supply Aluminium Coil,Aluminum Circles,Aluminium discs,Aluminum Sheet,Aluminum Strip, Household Aluminum Foil,Aluminum Foil for Pharmaceutical Packaging,Aluminum Foil Tape,Aluminum Foil for Air Conditioner,Aluminum Foil for Container etc. series of aluminum products, sincerely welcome everyone to visit.

- Q: This question asks for a description of the various forms and dimensions of aluminum profiles that are typically utilized in the construction industry.

- <p>Aluminum profiles used in construction come in various shapes and sizes to cater to different structural needs. Common shapes include angles, channels, I-beams, H-beams, T-profiles, and rectangular or square tubes. Sizes vary based on the thickness of the aluminum and the dimensions of the profile, such as width, height, and length. For instance, an H-beam might have a depth ranging from 100mm to 900mm and a width from 50mm to 300mm. The selection of the right profile depends on the specific requirements of the construction project, such as load-bearing capacity, aesthetic considerations, and cost efficiency.</p>

- Q: Are there any materials for aluminum profiles?

- Aluminum material can be classified as follows:By purpose1. architectural aluminum profiles (divided into two types of doors and windows and curtain wall)2. radiator aluminum profiles.3. general industrial aluminum: mainly used in the manufacture of industrial production, such as automation equipment, covering the skeleton and the custom mold machinery and equipment according to their own requirements, such as assembly line conveyor belt, hoisting machine, glue machine, testing equipment, shelves and so on, the electrical machinery industry and clean room with.4, rail vehicle structure aluminum alloy profile: mainly used for rail vehicle body manufacturing.5, Mount Aluminum profiles, made of aluminum alloy frame, mounted a variety of exhibitions and decorative paintings.

- Q: I want to make my aluminum oxide, how much money is needed is a set of equipment? Please leave, thank you!

- The price of the equipment is not primary, mainly because of the technical requirements of oxidation. "This is not as simple as you think."

- Q: This question asks about the strength and suitability of aluminum profiles for outdoor applications.

- <p>Yes, aluminum profiles are strong enough for exterior use. They are lightweight, durable, and resistant to corrosion, making them ideal for outdoor applications. Aluminum profiles can withstand various weather conditions and maintain their strength over time. They are also low-maintenance, as they do not rust or rot, and can be easily cleaned. Additionally, aluminum profiles can be anodized or powder-coated for enhanced durability and resistance to UV rays, further ensuring their suitability for exterior use.</p>

- Q: Are aluminum profiles suitable for use in roofing systems in areas with high wind conditions?

- <p>Yes, aluminum profiles can be used for roofing systems in windy regions. Aluminum is a lightweight and durable material that can withstand high winds. It is often used in the construction of roofing systems because of its strength and resistance to corrosion. Additionally, aluminum profiles can be designed to meet specific wind load requirements, making them suitable for areas prone to strong winds. However, the design and installation of the roofing system must be done correctly to ensure it can handle the wind forces.</p>

- Q: What are the different types of surface protection for aluminum profiles?

- There are several types of surface protection for aluminum profiles, including anodizing, powder coating, painting, and laminating. Anodizing involves creating a durable oxide layer on the surface of the aluminum, providing corrosion and wear resistance. Powder coating involves applying a dry powder to the surface and then curing it with heat, creating a tough and decorative finish. Painting involves applying liquid paint to the surface, providing both protection and aesthetic appeal. Laminating involves applying a layer of protective film or sheet to the surface, offering scratch resistance and added durability.

- Q: This question asks for a list of various aluminum profiles that are utilized in the construction of building facades and cladding systems.

- <p>Aluminum profiles for facades and cladding systems come in various types, each serving specific purposes in construction. Common types include: 1. <strong>Aluminum Extrusions</strong>: Used for structural support and can be customized for specific design requirements. 2. <strong>Aluminum Channels</strong>: Often used for attaching panels or as a part of the support structure. 3. <strong>Aluminum Angles</strong>: Provide corner support and reinforcement. 4. <strong>Aluminum Flat Bars</strong>: Used for horizontal or vertical support in facade systems. 5. <strong>Aluminum Tubes</strong>: Can be used as a decorative element or for structural reinforcement. 6. <strong>Aluminum Louvers</strong>: Designed for sun shading and ventilation. 7. <strong>Aluminum Panels</strong>: Can be flat or profiled, used for the outer layer of the facade. 8. <strong>Aluminum Trims and Mouldings</strong>: Used for finishing and detailing around windows, doors, and edges. Each type is chosen based on the architectural design, structural requirements, and aesthetic preferences.</p>

- Q: Can aluminum profiles be used in display stand and podium manufacturing?

- Absolutely, display stands and podiums can certainly benefit from the utilization of aluminum profiles. The utilization of aluminum, as a versatile and robust material, offers a multitude of advantages for these particular applications. The lightweight yet sturdy nature of aluminum profiles renders them exceptionally suitable for the creation of both portable and resilient display stands and podiums. The capability to easily tailor and fabricate aluminum profiles in order to meet specific design prerequisites allows for a high degree of flexibility in the creation of distinctive and attention-grabbing display stands and podiums. Moreover, the remarkable corrosion resistance exhibited by aluminum profiles guarantees that the displays and podiums will maintain a pristine appearance and endure for an extended period, even when subjected to outdoor or high-traffic environments. In conclusion, opting to incorporate aluminum profiles in the manufacturing of display stands and podiums is a prudent decision owing to their versatility, strength, and durability.

- Q: How do aluminum profiles perform in wind-resistant structures?

- Aluminum profiles are known for their excellent performance in wind-resistant structures. Due to their inherent strength and durability, they are able to withstand high wind pressures and maintain structural integrity. The lightweight nature of aluminum makes it an ideal material for constructing wind-resistant structures as it reduces the overall load on the building without compromising its strength. Aluminum profiles have high tensile strength and are resistant to corrosion, making them suitable for withstanding harsh weather conditions, including strong winds. They also have a high stiffness-to-weight ratio, meaning they can effectively distribute the wind load and minimize deflection. This characteristic is essential in wind-resistant structures as it helps to prevent excessive movement and ensures the safety of the building and its occupants. Furthermore, aluminum profiles can be easily fabricated and customized, allowing for the creation of complex and innovative designs. This flexibility in design enables architects and engineers to optimize the aerodynamics of the structure, further enhancing its resistance to wind forces. Additionally, aluminum profiles can be combined with other materials, such as glass or composite panels, to create a more robust and efficient wind-resistant system. Overall, aluminum profiles are highly reliable and efficient in wind-resistant structures. Their strength, lightweight nature, corrosion resistance, and flexibility in design make them an excellent choice for constructing buildings that can withstand strong winds and ensure the safety and longevity of the structure.

- Q: Can aluminum profiles be used in load-bearing structures?

- Yes, aluminum profiles can be used in load-bearing structures. Aluminum is a lightweight and durable material that offers high strength-to-weight ratio, making it suitable for load-bearing applications. It is commonly used in construction, aerospace, and automotive industries where its strength and structural integrity are essential.

Send your message to us

High Quality Aluminum Profiles Sliding Screen Door Wafer with a Good Price

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords