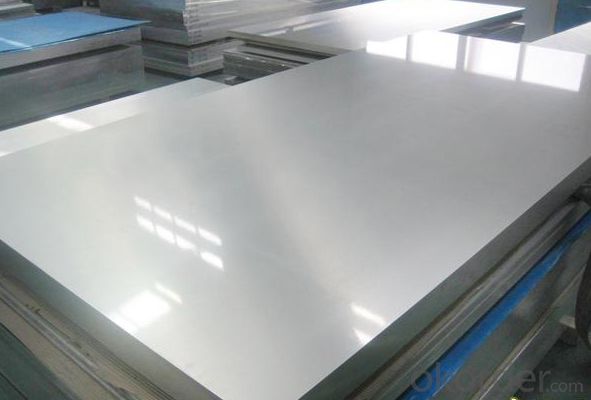

High Quality Aluminum Sheets for Photo Printing with Width up to 2620mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

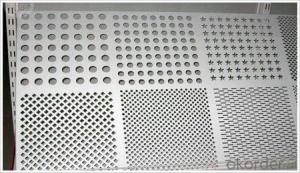

Pattern: orange peel, aluminum sheet5 bar,half a ball,diamond,compass shape

1.Orange peel aluminum sheet/coil

1)Alloy :1060 1100 1050 3003 3004 3105 5052

2)Temper :0 H114 H24 H32

3) Specification thickness:0.2mm-3.0mm

width:50mm-1300mm

Length: according your request

4)Application: Refrigeration. Air-conditioner. keep warm well such as pipe ,tank

5)Surface: No crack,canker, hole

2. aluminum sheet5 bar/coil

1)Alloy :1060 1100 1050 3003 3004 3105 5052 5754 5083 6061 6063 6082

2)Temper: O H114H194 T6

3) Specification: Thickness:1.0mm-10mm

Width:50mm-2000mm

Length: according your request

4)Application: the main function is anti-skidding,widely used in automobile manufacturing,shipbuilding,machine manufacturing,elerator,workshop

5)Surface: No crack,canker, hole

3.Compass shape aluminum sheet/coil

1)Alloy:1060 1100 1050 3003 3004 3105 5052 5754 5083 6061 6063 6082

2)Temper: O H114 H194 T6

3) Specification: thickness:1.0mm-10mm

width:50mm-2000mm

Length: according your request

4)Application: the main function is anti-skidding,widely used in automobile manufacturing,shipbuilding,machine manufacturing,elerator,workshop

5)Surface: No crack,canker, hole

4.Diamond aluminum sheet/coil

1)Alloy:1060 1100 1050 3003 3004 3105 5052 5754 5083 6061 6063 6082

2)Temper: O H114 H194 T6

3) Specification: Thickness:1.0mm-10mm

Width:50mm-2000mm

Length: according your request

4)Application: building industry,packing,decorative

5)Surface: No crack,canker, hole

4) Delivery time: 15-20 days after confirming order.

For all above:

1) Minimum order quantity: 5 tons per size.

2) The term of payment: T/T, irrevocable L/C at sight.

3) Packing: Export standard, waterproof wooden,craft,plywood pallet,etc.

- Q: What is the typical impact strength of aluminum sheets?

- The typical impact strength of aluminum sheets can vary depending on factors such as alloy composition, tempering, and thickness. However, generally, aluminum sheets have a moderate impact strength, making them suitable for many applications that require resistance to impact and denting.

- Q: ive been working with parts for a robot without gloves and ive manged to 3 cuts in my fingers, also my hands get covered with powdered aluminum from sanding the peices, can this be dangerous to my health?

- ALUMINUM DUSTS ARE CONSIDERED NUISANCE PARTICLUATES, WHICH HAVE LITTLE ADVERSE EFFECT ON LUNGS AND DO NOT PRODUCE SIGNIFICANT ORGANIC DISEASE OR TOXIC EFFECTS

- Q: Are aluminum sheets suitable for architectural facades?

- Yes, aluminum sheets are highly suitable for architectural facades. They offer numerous benefits such as durability, lightweight construction, corrosion resistance, and versatility in design. Aluminum sheets can be easily shaped and formed into various sizes and shapes, allowing for creative and unique architectural designs. Additionally, their ability to withstand harsh weather conditions makes them a reliable choice for long-lasting facades.

- Q: Is aluminum sheet resistant to UV rays?

- Yes, aluminum sheet is resistant to UV rays.

- Q: what is better for my 96 mustang gt. porting and polishing my stock heads or getting aluminum heads. also could i do a 3v conversion?

- Port and polish could give you loads of power depending on how big and clean you want to go. Aluminum heads are nice, they are very expensive and will only disperse heat faster. Although they can warp as well if they are under too much heat. If I had to choose, I would choose the port and polish with a roller rocker rail and a high flow electric water pump. I'm sorry but I'm not sure what a 3v is?

- Q: Can the aluminum sheets be used for manufacturing heat shields?

- Aluminum sheets are capable of being utilized in the production of heat shields. Renowned for its remarkable thermal conductivity and remarkable heat resistance, aluminum is extensively employed in multiple sectors, such as automotive and aerospace, for the manufacturing of heat shields. The reflective and heat dissipation properties of aluminum sheets enable them to effectively counteract heat, rendering them an optimal material for this specific purpose. Furthermore, aluminum possesses the advantages of being lightweight and corrosion-resistant, thus making it a sensible selection for heat shield production.

- Q: This question asks whether it is possible to utilize stamped or embossed aluminum sheets for a specific project.

- <p>Yes, you can use stamped or embossed aluminum sheets in your project. These sheets are known for their strength, durability, and lightweight properties, making them ideal for various applications such as construction, automotive, and aerospace. Stamped aluminum sheets are formed by pressing the material into a specific shape, while embossed sheets have a raised pattern. Both types offer design flexibility and can be customized to meet specific project requirements. Ensure that the aluminum sheets you select meet the necessary specifications for your project, such as thickness, strength, and finish.</p>

- Q: i have a aluminum bicycle the first time i painted it i painted over the original paint(didnt know any better). The second time i sanded it down with some paint left on it. Now this time im sanding it but im using 60grit it looks good to me is 60 grit to much.

- You screwed up. 60 grit should NEVER come in contact with aluminum... those scratches will never come out. NEVER have an aluminum frame sandblasted. You'll need to have it soda blasted or walnut shell blasted. You should be using 220 grit ALUMINUM OXIDE paper- it is white in color. My bet is that you are using garnet- the brown stuff, or maybe coated paper. You MUST use aluminum oxide. I have answered the question to paint a bike a hundred times. Just click on Discover and type in the words paint a bike without quotes. Theres your answer.

- Q: Is it possible to utilize aluminum sheets for the construction of outdoor advertising billboards?

- <p>Yes, aluminum sheets are commonly used for outdoor advertising billboards due to their durability, lightweight, and resistance to weather conditions. They are easy to install, maintain, and can be printed with high-quality graphics. Additionally, aluminum's corrosion resistance makes it a sustainable choice for long-term outdoor use.</p>

- Q: What are the different types of alloys used in aluminum sheets?

- There are several types of alloys used in aluminum sheets, including 1100, 3003, 5052, and 6061. These alloys have different properties and are chosen based on the specific application and desired characteristics of the aluminum sheet.

Send your message to us

High Quality Aluminum Sheets for Photo Printing with Width up to 2620mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords