High Quality Aluminum Extrusion Profiles C Channel with a Good Price

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

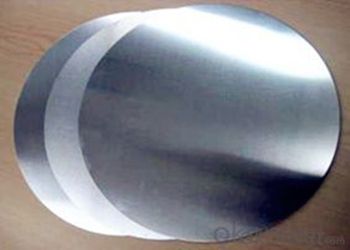

Aluminum Circles

Product introduction

Aluminum Circles are widely used in electronics, cosmetic, medicine, culture and education and auto parts. Electrical appliances, heat preservation, machinery manufacturing, automotive, aerospace,military, mold,construction,printing and other industries. Such as kitchen utensils such as non-stick pan,pressure cookers and other hardware supplies such as shades,water heaters shell,is the largest amount of aluminum alloy strip deep processing of one of the products.

Production methods

Punch processing

1. rough material cut (cut into a square) 2. Blank (punching into the Aluminum discs you want)

If it is a roll material, it is necessary to open the material.

Aluminum Circles Picture

Alloy state

Main series: 1 series, 3 series, 5 series, 6 series, 8 series is in the majority.

State : O, H ;

Introduction of our company

Our company is a professional Aluminium Coil Suppliers and Aluminum Circles manufacturers,mainly supply Aluminium Coil,Aluminum Circles,Aluminium discs,Aluminum Sheet,1100 Aluminum Sheet,1050 Aluminum Sheet,1060 Aluminum Sheet, Household Aluminum Foil,Aluminum Foil for Pharmaceutical Packaging,Aluminum Foil Tape,Aluminum Foil for Air Conditioner,Aluminum Foil for Container ,Aluminum Circles for Kitchenware,Aluminum Disc for Cookware,Aluminium Circle Sheet etc. series of aluminum products, sincerely welcome everyone to visit.

- Q: What type of aluminum alloy profile is used for high-rise balcony?

- Aluminum alloy doors and windows in the material, materials, there are 6 main areas, you can refer to:1, thickness: aluminum alloy sliding door has 70 series, 90 series of two, residential interior aluminum sliding door with 70 series can be. Series numbers indicate the mm mm of the thickness of the door frame. The aluminium alloy sliding window has 55 series, 60 series, 70 series, 90 series four kinds. According to the window size and selected a series of local wind pressure value set. The aluminium alloy sliding window used as a closed balcony shall be no less than 70 series.2, chromaticity: the same aluminum alloy profile color should be consistent, such as color difference is obvious, that is not appropriate to buy.3, strength: tensile strength should reach 157 mm per square meter Newton, the yield strength to reach 108 Newton per square millimeter. When buying, you can use your hand to bend the profile properly. After you let go, you should be able to return to the original condition.4, flatness: check the aluminum alloy profile surface should be no dent or drum out.5, oxidation: oxide film thickness should reach 10 microns. When you buy it, you can light it on the surface of the section to see if the oxide film on it can be wiped off.6, gloss: aluminum alloy doors and windows, to avoid the surface has open bubbles (white dots) and ash (black spots), as well as cracks, burrs, peeling and other obvious defects profiles.

- Q: Can aluminum profiles be used in the construction of data centers?

- Yes, aluminum profiles can be used in the construction of data centers. Aluminum profiles have several advantages that make them suitable for use in this industry. Firstly, aluminum is lightweight yet strong, making it an ideal material for constructing structures that need to support heavy loads. Data centers often house racks of servers and other equipment, so using aluminum profiles can provide the necessary strength without adding excessive weight. Secondly, aluminum profiles are highly customizable and can be easily fabricated to meet specific design requirements. This flexibility allows for efficient use of space within a data center, as the profiles can be tailored to fit the layout and dimensions of the facility. Additionally, aluminum is resistant to corrosion, which is crucial in a data center environment where equipment generates heat and humidity levels can be high. By using aluminum profiles, the risk of rust and corrosion is minimized, ensuring the longevity and reliability of the infrastructure. Furthermore, aluminum is a sustainable and recyclable material, which aligns with the growing demand for environmentally friendly construction practices. Using aluminum profiles in data center construction contributes to reducing the carbon footprint of the facility. In summary, aluminum profiles can indeed be used in the construction of data centers due to their strength, customization capabilities, resistance to corrosion, and sustainability.

- Q: Can aluminum profiles be used in electrical panel manufacturing?

- Yes, aluminum profiles can be used in electrical panel manufacturing. Aluminum is a lightweight and durable material that is highly conductive and resistant to corrosion, making it suitable for electrical applications. It is commonly used to construct the framework and housing of electrical panels due to its strength and ability to dissipate heat effectively.

- Q: What are the different packaging options for aluminum profiles?

- Some of the different packaging options for aluminum profiles include bundles or packs wrapped in plastic or stretch film, wooden crates or pallets, cardboard boxes, and custom-designed packaging solutions for specific profiles or customer requirements.

- Q: Are there any limitations or drawbacks to using aluminum profiles?

- Yes, there are some limitations and drawbacks to using aluminum profiles. Firstly, aluminum is a relatively soft metal compared to steel, which means it may not be as strong or durable in certain applications. Additionally, aluminum profiles can be more expensive than other materials such as wood or plastic. They also have lower resistance to high temperatures, which can lead to warping or deformation. Finally, aluminum profiles may require additional surface treatments or coatings to protect against corrosion in certain environments.

- Q: Are aluminum profiles suitable for use in electronics manufacturing?

- Yes, aluminum profiles are suitable for use in electronics manufacturing. Aluminum is a lightweight yet durable material that offers excellent thermal conductivity, making it ideal for dissipating heat generated by electronic components. Its high strength-to-weight ratio allows for the creation of sturdy and lightweight structures, which is advantageous in electronics manufacturing where weight reduction is often desired. Additionally, aluminum profiles can be easily machined, welded, and formed into various shapes, providing flexibility in design and customization. The corrosion resistance of aluminum also ensures longevity and reliability in electronic devices. Overall, the properties of aluminum make it a suitable choice for use in electronics manufacturing.

- Q: How are aluminum profiles joined together?

- Depending on the desired strength, functionality, and aesthetic appeal, various methods can be employed to join aluminum profiles. The most commonly utilized techniques include mechanical fastening, welding, and adhesive bonding. When it comes to ease of assembly and disassembly, mechanical fastening is a preferred option. Screws, bolts, nuts, rivets, and self-tapping screws are frequently employed to connect aluminum profiles, ensuring a stable and secure joint that allows for easy adjustment or dismantling. Welding, on the other hand, presents an effective means of joining aluminum profiles. Techniques such as TIG (Tungsten Inert Gas) or MIG (Metal Inert Gas) can be applied to melt and fuse the profiles together, resulting in a strong and permanent joint. Welding finds common usage in structural applications where high strength and rigidity are imperative. For a more visually appealing connection, adhesive bonding is often employed. Industrial-grade adhesives specifically formulated for aluminum bonding create a robust bond between the profiles. This method offers a seamless appearance, with no visible fasteners or weld marks. Adhesive bonding is commonly utilized in architectural applications, where a clean and sleek finish is desired. In certain instances, a combination of these methods may be employed to achieve the desired joint. For example, adhesive bonding can secure the profiles together, while mechanical fasteners provide additional strength and stability. Ultimately, the choice of joining method is contingent upon factors such as the application, required strength, accessibility, and desired appearance. Manufacturers and fabricators meticulously consider these factors to determine the most suitable method for joining aluminum profiles.

- Q: Will the aluminum profile be deformed at about 100 degrees?

- Of course, you only choose the quality of aluminum, as far as possible to choose the hardness of high bar, 5052, 5056, 6082, 7075 and so on are high strengthAluminium alloy。Our common 6063-T5 material, the door and window material is the material.

- Q: Are aluminum profiles suitable for automotive racks and carriers?

- Aluminum profiles, indeed, possess the appropriateness for automotive racks and carriers. Being both lightweight and robust, aluminum emerges as an optimal material for instances that prioritize weight reduction, such as automotive racks and carriers. The adaptability and flexibility of aluminum profiles enable their design and engineering to cater to specific requirements, facilitating customization. Besides, aluminum's resistance to corrosion guarantees the endurance and long-lasting nature of automotive racks and carriers, even in unfavorable weather conditions. Moreover, the notable strength-to-weight ratio of this material contributes to an enhanced fuel efficiency and reduced emissions. In summary, aluminum profiles furnish a dependable and efficient resolution for automotive racks and carriers.

- Q: RT: you! What are coated aluminum profiles? What's the surface treatment? What's the difference between grain transfer and wood grain transfer? Thank you first!!!

- Aluminum Alloy profiles the most common and most primitive (referred to as aluminum), is Aluminum Alloy itself color, silver white, but this state for a long time, Aluminum Alloy surface will be oxidized into a dark gray or black. In order to solve this problem, the most common practice in our country is to spray a layer of powder (high temperature treatment) on the surface, that is electrostatic powder spraying. Also, fluorocarbon electrophoresis processing processing, wood grain transfer, the transfer grain processing fidelity is not high, in order to understand this problem quickly, the market has a film processing, high fidelity, but because the process requirements must be done in the film before powder spraying treatment, coupled with higher requirement on the film itself (the country is more before foreign or joint ventures), so the production cost is higher, in a second tier city high-grade residential.

Send your message to us

High Quality Aluminum Extrusion Profiles C Channel with a Good Price

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords