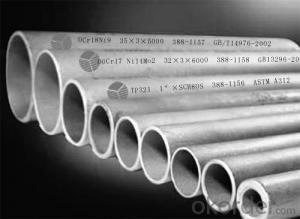

High Pressure Gas Cylinder Seamless Steel Pipe

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5mt m.t.

- Supply Capability:

- 5000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Seamless Steel Pipe

Application of High Pressure Gas Cylinder Seamless Steel Pipe

The company products including seamless steel gas cylinder

for industry and medical gas use. We can make cylinder

Standard of High Pressure Gas Cylinder Seamless Steel Pipe

DOT3AA, JIS8241, EN1964, GB5099

ISO9809,GB5099, KSB6210.

Certificate of High Pressure Gas Cylinder Seamless Steel Pipe

CCS,BV, LLODY'S, ABS.

Description of High Pressure Gas Cylinder Seamless Steel Pipe

Material | 34Mn2V/37Mn/30CrMo |

Nominal Diameter | 219/232/267/279/325(mm) |

Water Capacity | 20-80(L) |

Nominal Height | 815-1780(mm) |

Nominal Weight | 30.5-103(kg) |

Service Pressure | 15/20(MP) |

Wall Thickness | 4.7-7.0(mm) |

Packing of High Pressure Gas Cylinder Seamless Steel Pipe

Black paint or varnish ,plastic caps with the both ends

- Q: What type of steel pipe dance is used in general?

- The steel pipe fittings used in the pipe dance are made of smooth surface material, usually chrome or polished by steel or iron.

- Q: Can steel pipes be used for the construction of offshore platforms?

- Yes, steel pipes can be used for the construction of offshore platforms. Steel pipes are commonly used in offshore construction due to their high strength, durability, and resistance to corrosion in harsh marine environments. They are suitable for various applications, including the fabrication of jacket legs, risers, pile sleeves, and other structural components necessary for offshore platform construction.

- Q: How are steel pipes used in airport infrastructure?

- Steel pipes are used in airport infrastructure for a variety of applications such as constructing hangars, fuel distribution systems, water supply networks, and underground utility lines. They provide structural support, durability, and resistance to extreme weather conditions, making them essential for the smooth functioning and long-term reliability of airport facilities.

- Q: How do you calculate the pipe flow velocity coefficient for steel pipes?

- The Manning's equation is employed to determine the flow velocity in open channels and pipes, taking into consideration the hydraulic radius, slope, and roughness coefficient of the pipe. By applying this equation, the pipe flow velocity coefficient for steel pipes can be calculated. To ascertain the pipe flow velocity coefficient for steel pipes, the following steps should be followed: 1. Calculate the hydraulic radius (R) of the steel pipe by dividing the cross-sectional area (A) of the pipe by the wetted perimeter (P). The formula to use is R = A/P. 2. Determine the slope (S) of the pipe, which is the change in elevation divided by the length of the pipe. Usually, it is expressed as a ratio or a percentage. 3. Obtain the roughness coefficient (n) of the steel pipe, representing the internal roughness of the pipe. This information can be found in literature or pipe manufacturer specifications, often given in terms of the Manning's roughness coefficient. 4. Insert the values of hydraulic radius (R), slope (S), and roughness coefficient (n) into the Manning's equation: V = (1/n) * R^(2/3) * S^(1/2) where V signifies the flow velocity. 5. Solve the equation for V to calculate the pipe flow velocity coefficient for steel pipes. It is crucial to note that the calculated velocity coefficient may differ depending on specific pipe dimensions, flow conditions, and other factors. Therefore, it is advisable to consult relevant engineering standards or seek guidance from a hydraulic engineer to ensure accurate and reliable calculations for specific applications.

- Q: Are steel pipes suitable for industrial cooling systems?

- Indeed, steel pipes prove to be generally well suited for industrial cooling systems. Being a robust and long-lasting material, steel can endure the elevated pressures and temperature fluctuations commonly encountered in such systems. Furthermore, its exceptional resistance to corrosion renders it an ideal choice for utilization with water or other coolants. Moreover, steel pipes exhibit commendable thermal conductivity, facilitating efficient heat transfer during the cooling procedure. Additionally, these pipes are conveniently accessible and cost-effective, rendering them highly favored within industrial settings.

- Q: Can steel pipes be used for conveying compressed air?

- Yes, steel pipes can be used for conveying compressed air. Steel pipes are commonly used in applications where high pressure and durability are required, such as in industrial settings. Steel pipes have a high tensile strength and can withstand the high pressures generated by compressed air systems. Additionally, steel pipes are resistant to corrosion, which is important when dealing with moisture in compressed air. However, it is important to ensure that the steel pipes are properly sized and rated for the specific pressure and flow requirements of the compressed air system. Additionally, proper installation and maintenance practices should be followed to prevent any potential leaks or failures.

- Q: What is the difference between seamless steel pipe and welded pipe?

- The main molding process is different. Ordinary steel pipes, such as tap water pipes, are usually welded by bending flat plates, and you can find a seam on it;

- Q: How can two smooth steel pipes be joined? The size of the two pipe is different (except for welding)

- Butt fastener: used for connecting two steel pipe jointsThin-walled stainless steel pipe, the national standard consists of three parts, respectively on the thin stainless steel pipe connection, the sealing ring of raw materials of various specifications of O type thin wall stainless steel pipe diameter and wall thickness of pipe and rubber have clear requirements, in order to ensure the quality of the whole pipeline, pipeline safety and guarantee system durability. The connection mode is clamp type and ring type.

- Q: How are steel pipes used in the aerospace manufacturing industry?

- Steel pipes are commonly used in the aerospace manufacturing industry for various purposes such as hydraulic systems, fuel lines, and structural components. They offer excellent strength, durability, and resistance to high temperatures, making them ideal for carrying fluids and supporting the overall structure of aircraft.

- Q: How are steel pipes used in the construction of railway tracks?

- Steel pipes are commonly used in the construction of railway tracks as they provide a strong and durable foundation. These pipes are usually used as support structures for the tracks, serving as a base on which the rails are laid. They help to distribute the weight of the trains evenly, ensuring stability and reducing the risk of track failure. Additionally, steel pipes are used for drainage purposes, allowing water to flow freely and preventing damage to the tracks.

1. Manufacturer Overview

| Location | Zhejiang, China |

| Year Established | 2007 |

| Annual Output Value | Below US$1 Million |

| Main Markets | |

| Company Certifications | API;ISO9001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 300-500 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | 360,000 Squre meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | High Average |

Send your message to us

High Pressure Gas Cylinder Seamless Steel Pipe

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5mt m.t.

- Supply Capability:

- 5000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords